Question

You work in a company that manufactures steel springs for car suspensions. These are made from quenched and tempered 1095 steel and require the hardness

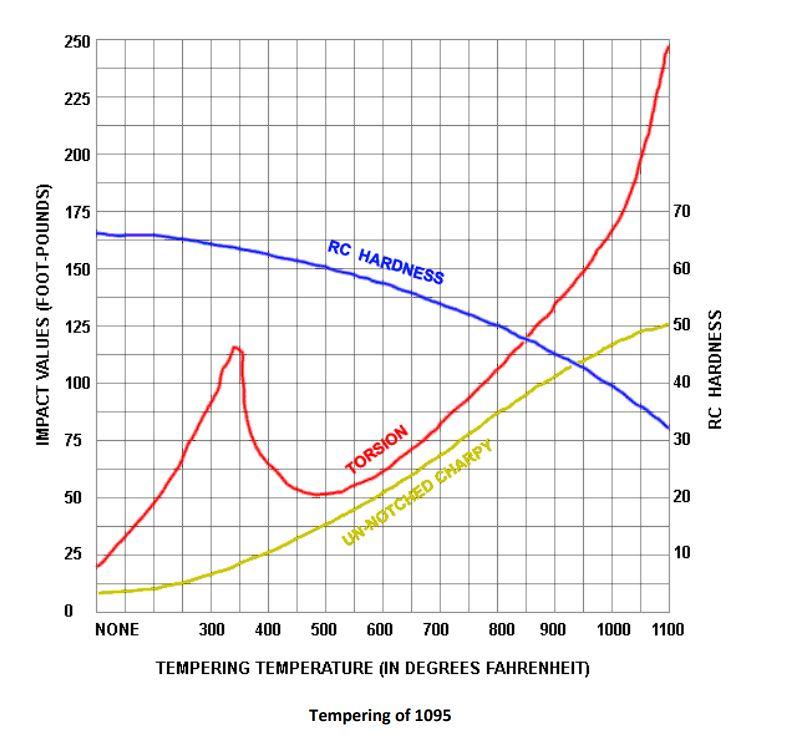

You work in a company that manufactures steel springs for car suspensions. These are made from quenched and tempered 1095 steel and require the hardness to be above 55 Rc and the unnotched impact energy to be greater than 70J. Inadvertently, the springs were painted the wrong color. In order to remove the paint, a worker heated the springs with a gas torch until they glowed orange and then cooled them in a bucket of water before repainting them. A significant number of these springs were failing in service.

(a) Explain what has happened to the material and why it is failing

(b) Can the properties of the material be restored to the correct values and if so, how.

(c) If the springs were instead made from precipitation-hardened aluminum, what would change in properties would occur (explain the changes from a microstructural point of view). Note assume that the springs are not melted by the gas torch.

IMPACT VALUES (FOOT-POUNDS) 250 225 200 175 150 125 100 75 50 25 0 NONE RC HARDNESS TORSION UN NOTCHED CHARPY 300 400 500 600 700 TEMPERING TEMPERATURE (IN DEGREES FAHRENHEIT) Tempering of 1095 800 70 60 50 40 30 20 10 900 1000 1100 RC HARDNESS

Step by Step Solution

There are 3 Steps involved in it

Step: 1

a The material failure is likely due to the process of quenching and tempering 1095 steel being disrupted by the heating and rapid cooling quenching in water When steel is heattreated it undergoes a s...

Get Instant Access to Expert-Tailored Solutions

See step-by-step solutions with expert insights and AI powered tools for academic success

Step: 2

Step: 3

Ace Your Homework with AI

Get the answers you need in no time with our AI-driven, step-by-step assistance

Get Started