Answered step by step

Verified Expert Solution

Question

1 Approved Answer

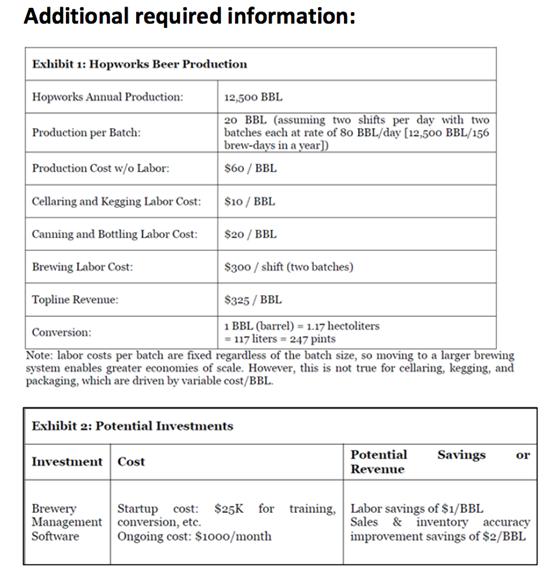

Calculate the present value of the annual savings when applying the new software during 6 years and 10 years. Additional required information: Exhibit 1: Hopworks

Calculate the present value of the annual savings when applying the new software during 6 years and 10 years.

Additional required information: Exhibit 1: Hopworks Beer Production Hopworks Annual Production: Production per Batch: Production Cost w/o Labor: Cellaring and Kegging Labor Cost: Canning and Bottling Labor Cost: Brewing Labor Cost: Topline Revenue: 12,500 BBL 20 BBL (assuming two shifts per day with two batches each at rate of 80 BBL/day [12,500 BBL/156 brew-days in a year]) $60/BBL Investment Cost $10/BBL $20/BBL Conversion: Note: labor costs per batch are fixed regardless of the batch size, so moving to a larger brewing system enables greater economies of scale. However, this is not true for cellaring, kegging, and packaging, which are driven by variable cost/BBL. Brewery Management conversion, etc. Software $300/shift (two batches) $325/BBL 1 BBL (barrel) = 1.17 hectoliters = 117 liters = 247 pints Exhibit 2: Potential Investments Potential Revenue Startup cost: $25K for training, Labor savings of $1/BBL Sales & inventory Ongoing cost: $1000/month Savings or accuracy improvement savings of $2/BBL

Step by Step Solution

★★★★★

3.34 Rating (157 Votes )

There are 3 Steps involved in it

Step: 1

The present value of the annual savings when applyi...

Get Instant Access to Expert-Tailored Solutions

See step-by-step solutions with expert insights and AI powered tools for academic success

Step: 2

Step: 3

Ace Your Homework with AI

Get the answers you need in no time with our AI-driven, step-by-step assistance

Get Started