Question

California Creamery, Inc. (CCI) owned and operated 14 retail ice cream stores spread throughout Southern California, from San Luis Obispo to San Diego. CCI's stores

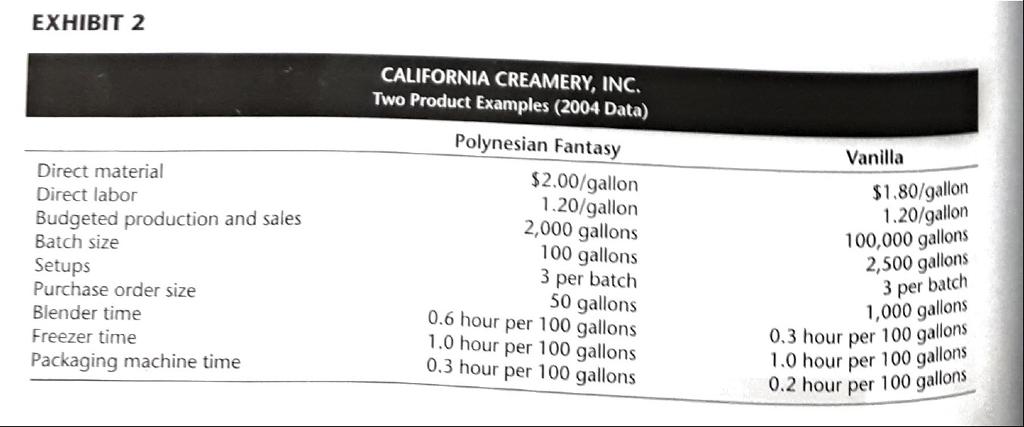

California Creamery, Inc. (CCI) owned and operated 14 retail ice cream stores spread throughout Southern California, from San Luis Obispo to San Diego. CCI's stores sold only the highest quality, ultra-premium ice cream. They offered 25 different ice cream flavors. Many of the CCI flavors were “exotic,” such as “Polynesian Fantasy,” “Mango-Lemon Supreme,” and “Multi-Nut Twist.” But CCI also sold a few traditional ice cream flavors, such as vanilla, chocolate, strawberry, and coffee. Some of the flavors were very popular, but a few of the exotic flavors sold in low volumes.

CCI produced its own ice cream. Originally the ice cream was produced in the garage of the company's founder, Will Forgey. But the company outgrew the garage, and Will had since leased a building to house CCI's production activities. As CCI had grown, Will had been able to afford more expensive, automated manufacturing equipment that blended the flavors and packaged the liquid ice cream in preparation for freezing. CCI's most significant production costs were for raw materials, particularly cream, sugar, and the special flavor ingredients, and for the acquisition, operation, and maintenance of the production equipment.

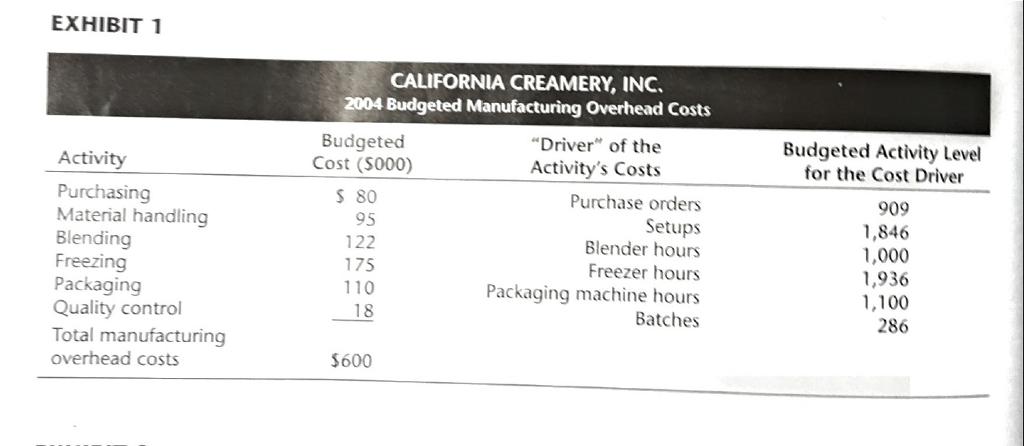

All of CCI's products were sold at the same retail price. Will set the prices to yield, roughly, a markup of 100% on average full production costs. CCI's 2004 budget included a manufacturing overhead of $600,000. To estimate product costs, Will spread this overhead cost to products based on a proportion of the direct labor used in the production process. CCI's total direct labor cost for 2004 was $300,000, so Will charged the overhead to products at a rate of 200% of direct labor costs.

One day in a casual conversation, Louise Fettinger, Will's neighbor and a controller of a small manufacturing company, suggested that Will's pricing policy was not very smart. Louise's intuition was that the costs of producing CCI's various flavors were very different. She thought those differences should be reflected in the prices charged, or CCI's profits would vary as the mix of products sold varied.

Question 1: State the problem of this case.

Question 2: Identify the case's objectives.

Question 3: Give alternative courses of action as regards to your statement of the problem (question 1 must be connected to your answers in question 3).

Question 4: Give recommendation.

Case questions (already answered, please do not answer)

1. Compute the full production cost (per gallon) of the Polynesian Fantasy and Vanilla products using:

a. Will's old costing method;

b. The new costing method (Louise's suggestion).

2. What are the effects, if any, of changing the company's costing method? Specifically, are the differences between the two costing methods material in terms of:

a. their effect on individual product costs?

b. their effect on total company profits? (Assume no changes in any operating decisions, such as prices and production volumes.)

If there are material differences, why do they exist? If there are no material differences, why do they not exist?

3. What should Will do now? Explain.

EXHIBIT 1 Activity Purchasing Material handling Blending Freezing Packaging Quality control Total manufacturing overhead costs CALIFORNIA CREAMERY, INC. 2004 Budgeted Manufacturing Overhead Costs Budgeted Cost (5000) $ 80 95 122 175 110 18 $600 "Driver" of the Activity's Costs Purchase orders Setups Blender hours Freezer hours Packaging machine hours Batches Budgeted Activity Level for the Cost Driver 909 1,846 1,000 1,936 1,100 286

Step by Step Solution

3.55 Rating (166 Votes )

There are 3 Steps involved in it

Step: 1

Get Instant Access to Expert-Tailored Solutions

See step-by-step solutions with expert insights and AI powered tools for academic success

Step: 2

Step: 3

Ace Your Homework with AI

Get the answers you need in no time with our AI-driven, step-by-step assistance

Get Started