Question: Can someone fill out this part using the information from the case study that is stated above? With its railroad access and presence of numerous

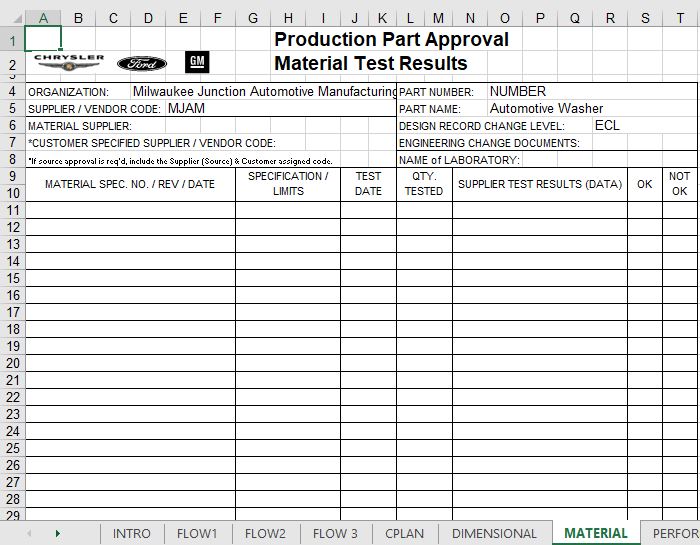

Can someone fill out this part using the information from the case study that is stated above?

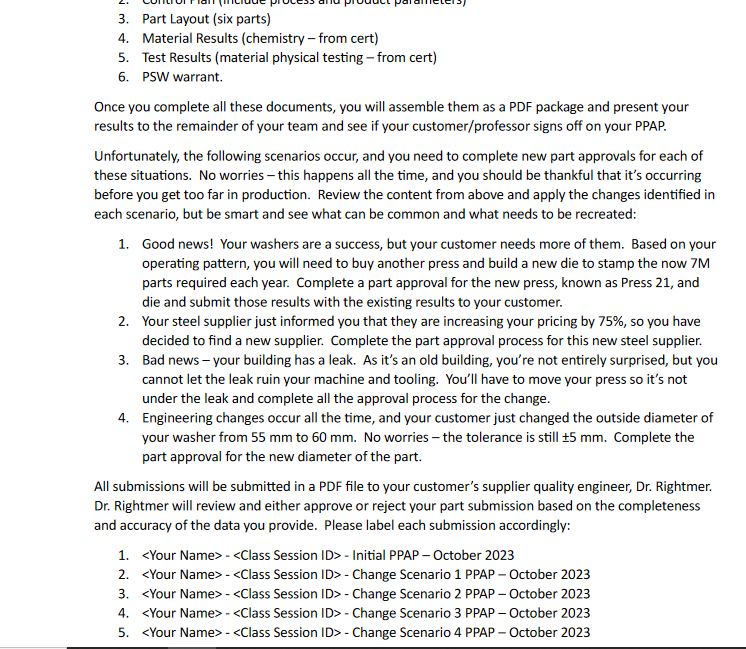

With its railroad access and presence of numerous automobile factories, Milwaukee Junction was considered the cradle of the automotive industry at the turn of the 20th century. Now, 100 years later, the automotive industry looks to make Milwaukee Junction the launchpad for its next century of growth and development. Instead of wooden horse carriages and body shops, electric vehicle components will be manufactured in this historic industrial hub. As Wayne State students, you understand Detroit and what it takes to thrive in the City of Champions and home of the automotive industry. The Milwaukee Junction Revitalization Project is not only significant to the next generation of automobiles, but the success of the facilities is critical to the resurgence of Detroit and Southeast Michigan. You've been selected to be part of the team that will stamp automotive washers in a reclaimed, historic automotive facility on Piquette Avenue. The plant will have 20 high speed stamping machines that will produce washers and special components for EV motor assemblies. The timing for this launch is almost as tight as the part tolerances, but it's nothing that is insurmountable. As mentioned before, your facility has 20 high speed presses, and you are responsible for launching a compound die that will be responsible for stamping 5M washers per year. The press, known as Press 20, will run at capacity, which includes appropriate time for die maintenance, and will be dedicated to this die for the entire year. To be clear, Press 20 does not have capacity for any more parts. To launch the product, you'll need to complete the following tasks to receive approval from your customer to begin production. All data you need will be taken from a preliminary part run, after which you will report the results to your customer. The following information will be used to complete your part approval. Part specifications: Outside Diameter: 55 mm 5 mm Inside Diameter: 20 mm 5 mm Material Thickness: 0.5 mm 0.1 mm Material Chemistry: See Material Cert Incoming Material: Coil Width: 60 mm Material Thickness: 0.5 mm Process Parameters: 100 strokes per minute

Step by Step Solution

There are 3 Steps involved in it

To complete the answer using the information from the case study address the specific requirements mentioned in the context Heres how you can approach ... View full answer

Get step-by-step solutions from verified subject matter experts