Answered step by step

Verified Expert Solution

Question

1 Approved Answer

can you explain this:Asap please! 1. bullwhip effect, order fulfillment (ETO, MTS) and the Figure. because i need to presenting. 15.11 INVENTORY MANAGEMENT Inventories are

can you explain this:Asap please!

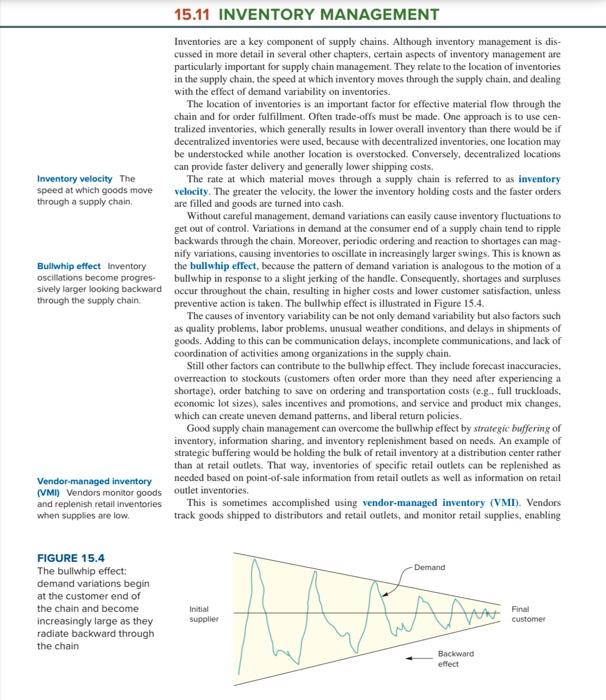

15.11 INVENTORY MANAGEMENT Inventories are a key component of supply chains. Although inventory management is dis- cussed in more detail in several other chapters, certain aspects of inventory management are particularly important for supply chain management. They relate to the location of inventories in the supply chain, the speed at which inventory moves through the supply chain, and dealing with the effect of demand variability on inventories. The location of inventories is an important factor for effective material flow through the chain and for order fulfillment. Often trade-offs must be made. One approach is to use cen- tralized inventories, which generally results in lower overall inventory than there would be if decentralized inventories were used, because with decentralized inventories, one location may be understocked while another location is overstocked. Conversely, decentralized locations can provide faster delivery and generally lower shipping costs, Inventory velocity The The rate at which material moves through a supply chain is referred to as inventory speed at which goods move velocity. The greater the velocity. the lower the inventory holding costs and the faster orders through a supply chain are filled and goods are turned into cash. Without careful management, demand variations can easily cause inventory fluctuations to get out of control. Variations in demand at the consumer end of a supply chain tend to ripple backwards through the chain. Moreover, periodic ordering and reaction to shortages can mag- nify variations, causing inventories to oscillate in increasingly larger swings. This is known as Bullwhip effect Inventory the bullwhip effect, because the pattern of demand variation is analogous to the motion of a Oscillations become progres bullwhip in response to a slight jerking of the handle. Consequently, shortages and surpluses sively larger looking backward occur throughout the chain, resulting in higher costs and lower customer satisfaction, unless through the supply chain preventive action is taken. The bullwhip effect is illustrated in Figure 15.4. The causes of inventory variability can be not only demand variability but also factors such as quality problems, labor problems. unusual weather conditions, and delays in shipments of goods. Adding to this can be communication delays, incomplete communications, and lack of coordination of activities among organizations in the supply chain. Still other factors can contribute to the bullwhip effect. They include forecast inaccuracies, overreaction to stockouts (customers often order more than they need after experiencing a shortage). order batching to save on ordering and transportation costs (e.g., full truckloads. economic lot sizes), sales incentives and promotions, and service and product mix changes, which can create uneven demand patterns, and liberal return policies. Good supply chain management can overcome the bullwhip effect by strategic buffering of inventory, information sharing, and inventory replenishment based on needs. An example of strategic buffering would be holding the bulk of retail inventory at a distribution center rather than at retail outlets. That way, inventories of specific retail outlets can be replenished as Vendor managed Inventory needed based on point-of-sale information from retail outlets as well as information on retail (VMI) Vendors monitor goods outlet inventories. and replenish retail inventories This is sometimes accomplished using vendor-managed inventory (VMI). Vendors when supplies are low track goods shipped to distributors and retail outlets, and monitor retail supplies, enabling Demand FIGURE 15.4 The bullwhip effect: demand variations begin at the customer end of the chain and become increasingly large as they radiate backward through the chain Initial Supplier Final customer Backward effect 15.12 ORDER FULFILLMENT Order fulfillment refers to the processes involved in responding to customer orders, Fulfill-Order fulfillment The pro- ment time can be an important criterion for customers. It is often a function of the degree of cesses involved in responding customization required. Here are some common approaches: to customer orders. Engineer-to-Order (ETO). With this approach, products are designed and built accord- ing to customer specifications. This approach is frequently used for large-scale construc- tion projects, custom homebuilding, home remodeling, and for products made in job shops. The fulfillment time can be relatively lengthy because of the nature of the proj- ect, as well as the presence of other jobs ahead of the new one. Make-to-Order (MTO). With this approach, a standard product design is used, but production of the final product is linked to the final customer's specifications. This approach is used by aircraft manufacturers such as Boeing. Fulfillment time is generally less than with ETO fulfillment, but still fairly long. Assemble-to-Order (ATO). With this approach, products are assembled to customer specifications from a stock of standard and modular components. Computer manufactur- ers such as Dell operate using this approach. Fulfillment times are fairly short, often a week or less. Make-to-Stock (MTS). With this approach, production is based on a forecast, and prod- ucts are sold to the customer from finished goods stock. This approach is used in depart- ment stores and supermarkets. The order fulfillment time is immediate. A variation of this is e-commerce, although goods have already been produced, there is a lag in fulfill- ment to allow for shipping. . 15.11 INVENTORY MANAGEMENT Inventories are a key component of supply chains. Although inventory management is dis- cussed in more detail in several other chapters, certain aspects of inventory management are particularly important for supply chain management. They relate to the location of inventories in the supply chain, the speed at which inventory moves through the supply chain, and dealing with the effect of demand variability on inventories. The location of inventories is an important factor for effective material flow through the chain and for order fulfillment. Often trade-offs must be made. One approach is to use cen- tralized inventories, which generally results in lower overall inventory than there would be if decentralized inventories were used, because with decentralized inventories, one location may be understocked while another location is overstocked. Conversely, decentralized locations can provide faster delivery and generally lower shipping costs, Inventory velocity The The rate at which material moves through a supply chain is referred to as inventory speed at which goods move velocity. The greater the velocity. the lower the inventory holding costs and the faster orders through a supply chain are filled and goods are turned into cash. Without careful management, demand variations can easily cause inventory fluctuations to get out of control. Variations in demand at the consumer end of a supply chain tend to ripple backwards through the chain. Moreover, periodic ordering and reaction to shortages can mag- nify variations, causing inventories to oscillate in increasingly larger swings. This is known as Bullwhip effect Inventory the bullwhip effect, because the pattern of demand variation is analogous to the motion of a Oscillations become progres bullwhip in response to a slight jerking of the handle. Consequently, shortages and surpluses sively larger looking backward occur throughout the chain, resulting in higher costs and lower customer satisfaction, unless through the supply chain preventive action is taken. The bullwhip effect is illustrated in Figure 15.4. The causes of inventory variability can be not only demand variability but also factors such as quality problems, labor problems. unusual weather conditions, and delays in shipments of goods. Adding to this can be communication delays, incomplete communications, and lack of coordination of activities among organizations in the supply chain. Still other factors can contribute to the bullwhip effect. They include forecast inaccuracies, overreaction to stockouts (customers often order more than they need after experiencing a shortage). order batching to save on ordering and transportation costs (e.g., full truckloads. economic lot sizes), sales incentives and promotions, and service and product mix changes, which can create uneven demand patterns, and liberal return policies. Good supply chain management can overcome the bullwhip effect by strategic buffering of inventory, information sharing, and inventory replenishment based on needs. An example of strategic buffering would be holding the bulk of retail inventory at a distribution center rather than at retail outlets. That way, inventories of specific retail outlets can be replenished as Vendor managed Inventory needed based on point-of-sale information from retail outlets as well as information on retail (VMI) Vendors monitor goods outlet inventories. and replenish retail inventories This is sometimes accomplished using vendor-managed inventory (VMI). Vendors when supplies are low track goods shipped to distributors and retail outlets, and monitor retail supplies, enabling Demand FIGURE 15.4 The bullwhip effect: demand variations begin at the customer end of the chain and become increasingly large as they radiate backward through the chain Initial Supplier Final customer Backward effect 15.12 ORDER FULFILLMENT Order fulfillment refers to the processes involved in responding to customer orders, Fulfill-Order fulfillment The pro- ment time can be an important criterion for customers. It is often a function of the degree of cesses involved in responding customization required. Here are some common approaches: to customer orders. Engineer-to-Order (ETO). With this approach, products are designed and built accord- ing to customer specifications. This approach is frequently used for large-scale construc- tion projects, custom homebuilding, home remodeling, and for products made in job shops. The fulfillment time can be relatively lengthy because of the nature of the proj- ect, as well as the presence of other jobs ahead of the new one. Make-to-Order (MTO). With this approach, a standard product design is used, but production of the final product is linked to the final customer's specifications. This approach is used by aircraft manufacturers such as Boeing. Fulfillment time is generally less than with ETO fulfillment, but still fairly long. Assemble-to-Order (ATO). With this approach, products are assembled to customer specifications from a stock of standard and modular components. Computer manufactur- ers such as Dell operate using this approach. Fulfillment times are fairly short, often a week or less. Make-to-Stock (MTS). With this approach, production is based on a forecast, and prod- ucts are sold to the customer from finished goods stock. This approach is used in depart- ment stores and supermarkets. The order fulfillment time is immediate. A variation of this is e-commerce, although goods have already been produced, there is a lag in fulfill- ment to allow for shipping 1. bullwhip effect, order fulfillment (ETO, MTS)

and the Figure.

because i need to presenting.

Step by Step Solution

There are 3 Steps involved in it

Step: 1

Get Instant Access to Expert-Tailored Solutions

See step-by-step solutions with expert insights and AI powered tools for academic success

Step: 2

Step: 3

Ace Your Homework with AI

Get the answers you need in no time with our AI-driven, step-by-step assistance

Get Started