The CCCC wishes to optimize its initial supply chain design as it takes advantage of new legalization laws in Canada for cannabis products. It expects

The CCCC wishes to optimize its initial supply chain design as it takes advantage of new legalization laws in Canada for cannabis products. It expects to expand and modify their cannabis distribution in the future, but they wish to maximize their profitability initially prior to the new market hitting equilibrium.

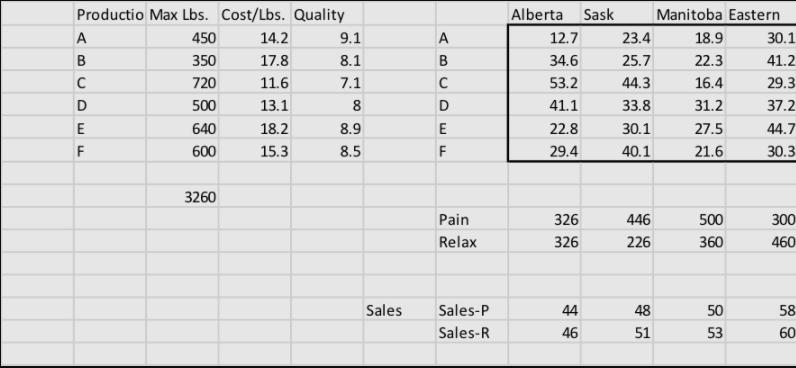

CCCC has 6 production facilities (Code named A,B,C,D,E and F) in which they can manufacture their two products: PAIN and RELAX. Raw cannabis is grown at various farms, and each production facility has been allocated the farm capacity (the specifics of this is not necessary for you to know). It has initial agreements reached with four distributors (Alberta, Sask, Manitoba, Eastern) that it will supply with the two products.

Each production facility has a maximum amount of products (in lbs.) that it can manufacture, characterized by the per pound cost, and the quality of the cannabis it expects to receive (on a 1-10 scale). Note that the maximum amount of lbs. used in production can be used in any combination between the two different products. (Your model will decide).

Each distributor has requested a maximum amount of each of the two products. Additionally, by legal contract, CCCC has to provide at least 50% of the maximum demand by product.

Also, to keep the production facilities happy, at least 70% of the estimated available cannabis must be shipped.

Two other items:

- Legal transport issues requires that no more than a total of 325 lbs. of cannabis can be shipped from any one production facility to any one distribution point. This 325 lb. limit includes both products combined.

- Quality: The quality of the products at each of the 4 distribution points must EACH average 8.3/lb. Thus, this will potentially impact how to production facilities supply the distribution points. Stated another way, all 8 combinations of products/distribution points must have a weighted quality average of at least 8.3.

CCCC wishes to determine how to optimally design its initial supply chain of sending two products from 6 production facilities to its 4 distribution points. All costs and revenues are measured on a per pound basis. Costs are production costs and shipping costs (see data provided). Revenues come from the amount of product reaching the distributors multiplied by their per pound sales price. The goal of your model is to maximize revenue less costs.

At the very end, when your model is working well, save the solution without integers and then force the variables to be integers. If it takes longer than 3 minutes, kill and save that solution. Summarize your solution with some sort of picture, graphic or discussion. Provide both solutions.

DATA

Revenues – See the Sales data for the two products at each distribution point.

Costs – Production cost (left table) and shipping cost (right table) – all per lb and all the same regardless of product.

Maximum production – shown on left – that is for both products combined.

Minimum production – must be 70% of Max by Production facility.

Maximum demand – Shown on right table – by product by distribution point.

Minimum demand is 50% of the maximum.

Don’t forget quality weighted average is by product by distribution point.

Legal transport is by production/distribution point pair – both products combined.

Productio Max Lbs. Cost/Lbs. Quality Alberta Sask Manitoba Eastern A 450 14.2 9.1 A 12.7 23.4 18.9 30.1 350 17.8 8.1 34.6 25.7 22.3 41.2 C 720 11.6 7.1 C 53.2 44.3 16.4 29.3 500 13.1 8 D 41.1 33.8 31.2 37.2 E 640 18.2 8.9 22.8 30.1 27.5 44.7 600 15.3 8.5 29.4 40.1 21.6 30.3 3260 Pain 326 446 500 300 Relax 326 226 360 460 Sales Sales-P 44 48 50 58 Sales-R 46 51 53 60

Step by Step Solution

3.52 Rating (179 Votes )

There are 3 Steps involved in it

Step: 1

See step-by-step solutions with expert insights and AI powered tools for academic success

Step: 2

Step: 3

Ace Your Homework with AI

Get the answers you need in no time with our AI-driven, step-by-step assistance

Get Started