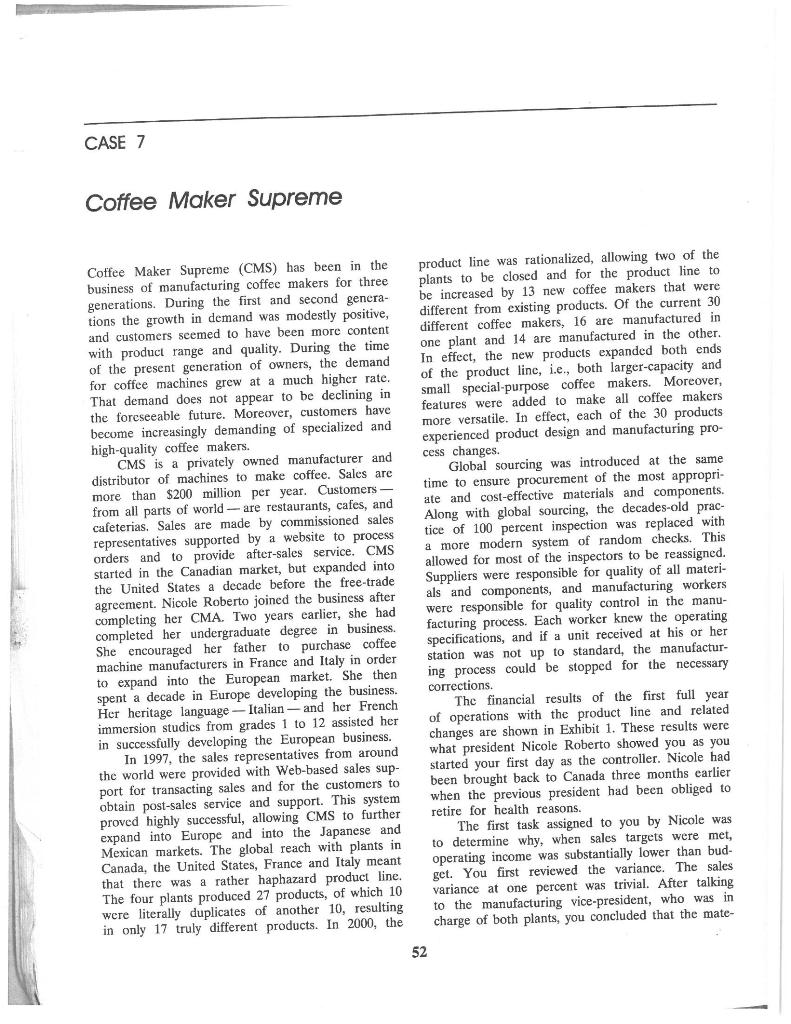

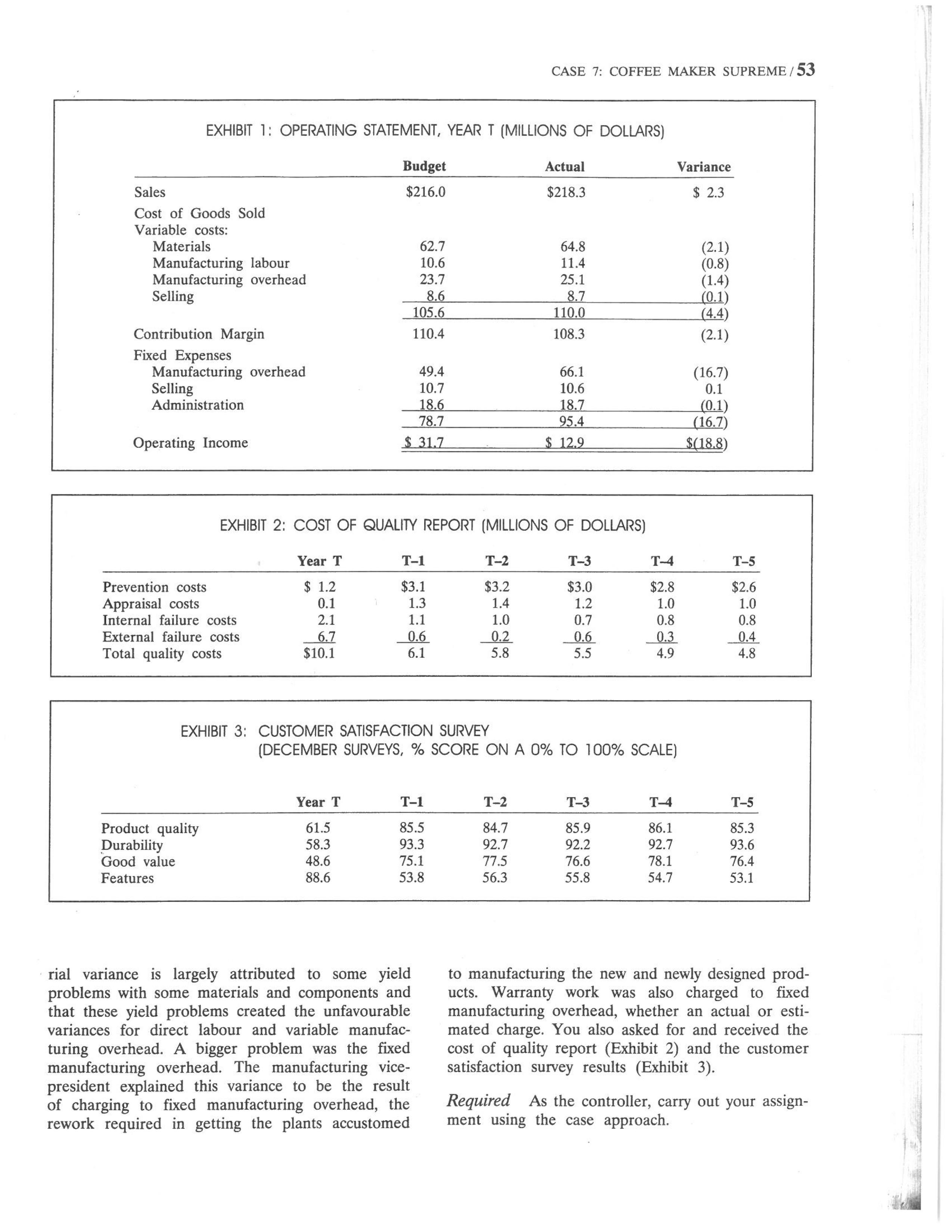

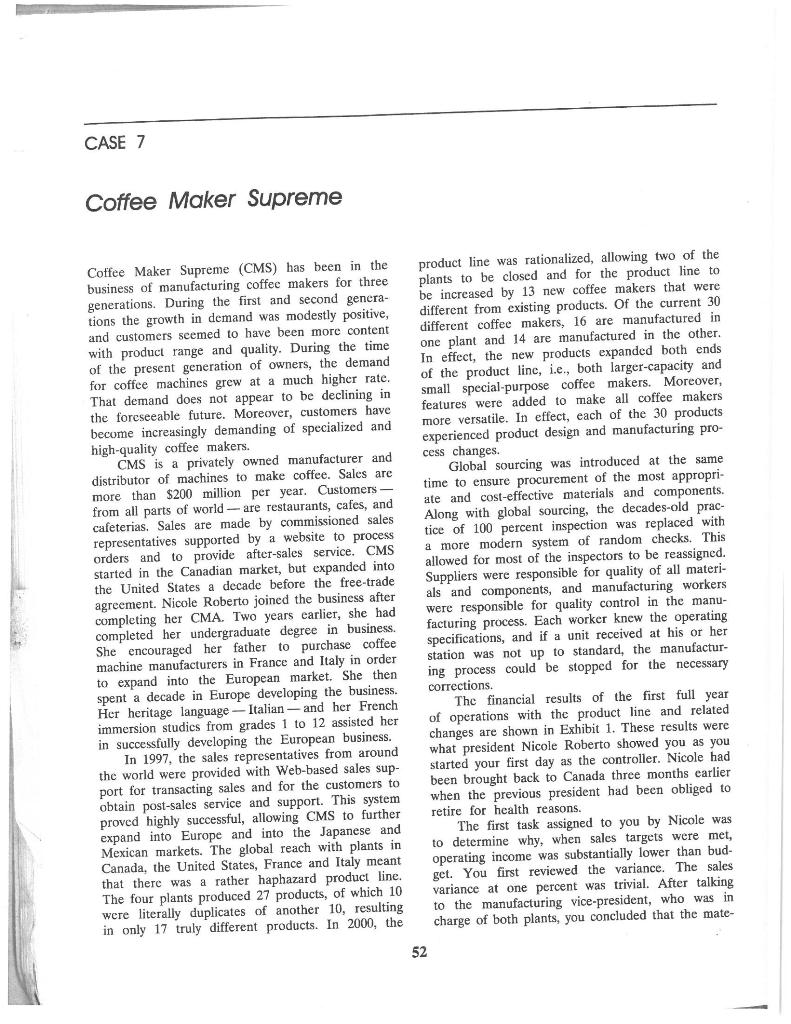

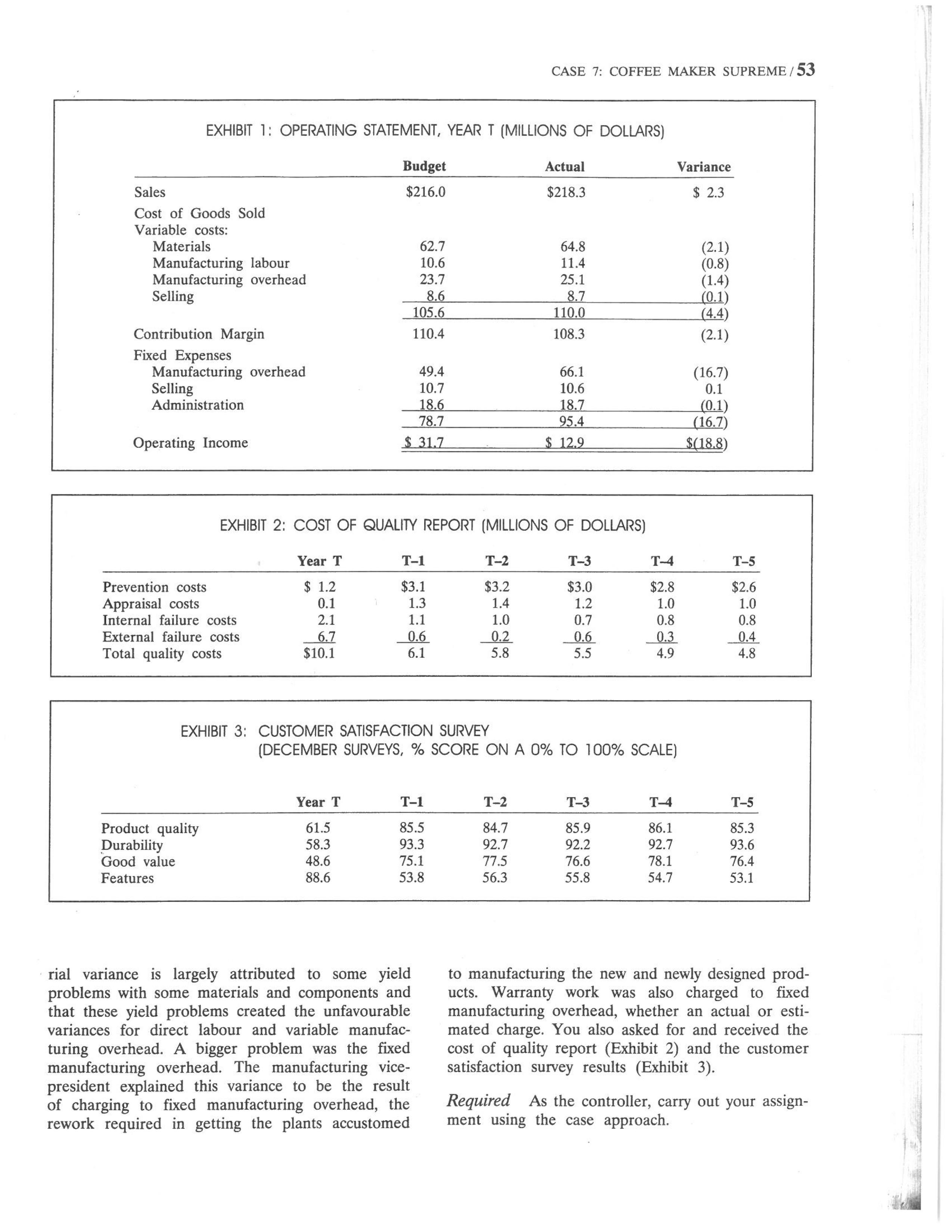

CASE 7 Coffee Maker Supreme ders Coffee Maker Supreme (CMS) has been in the business of manufacturing coffee makers for three generations. During the first and second genera- tions the growth in demand was modestly positive, and customers seemed to have been more content with product range and quality. During the time of the present generation of owners, the demand for coffee machines grew at a much higher rate. That demand does not appear to be declining in the foreseeable future. Moreover, customers have become increasingly demanding of specialized and high-quality coffee makers. CMS is a privately owned manufacturer and distributor of machines to make coffee. Sales are more than $200 million per year. Customers from all parts of world - are restaurants, cafes, and cafeterias. Sales are are made by commissioned sales supported by a website to process and to provide after-sales service. CMS started in the Canadian market, but expanded into the United States a decade before the free-trade agreement. Nicole Roberto joined the business after completing her CMA. Two years earlier, she had completed her undergraduate degree in business. She encouraged her father to purchase coffee machine manufacturers in France and Italy in order to expand into the European market. She then . spent a decade in Europe developing the business. Her heritage language Italian - and her French immersion studies from grades 1 to 12 assisted her in successfully developing the European business. In 1997, the sales representatives from around the world were provided with Web-based sales sup- port for transacting sales and for the customers to obtain post-sales service and support . This system proved highly successful, allowing CMS to further expand into Europe and into the Japanese and Mexican markets. The global reach with plants in Canada, the United States, France and Italy meant that there was a rather haphazard product line. The four plants produced 27 products, of which 10 were literally duplicates of another 10, resulting in only 17 truly different products. In 2000, the product line was rationalized, allowing two of the plants to be closed and for the product line to be increased by 13 new coffee makers that were different from existing products. Of the current 30 different coffee makers, 16 are manufactured in one plant and 14 are manufactured in the other. In effect, the new products expanded both ends of the product linc, i.e., both larger-capacity and small special-purpose coffee makers. Moreover, features were added to make all coffee makers more versatile. In effect, each of the 30 products experienced product design and manufacturing pro- cess changes. Global sourcing was introduced at the same time to ensure procurement of the most appropri ate and cost-effective materials and components. Along with global sourcing, the decades-old prac- tice of 100 percent inspection was replaced with a more modern system of random checks. This allowed for most of the inspectors to be reassigned. Suppliers were responsible for quality of all materi- als and components, and manufacturing workers were responsible for quality control in the manu- facturing process. Each worker knew the operating specifications, and if a unit received at his or her station was not up to standard, the manufactur- ing process could be stopped for the necessary The financial results of the first full year of operations with the product line and related changes are shown in Exhibit 1. These results were what president Nicole Roberto showed you as you started your first day the controller. Nicole had been brought back to Canada three months earlier when the previous president had been obliged to retire for health reasons. The first task assigned to you by Nicole was to determine why, when sales targets were met, operating income was substantially lower than bud- get. You first reviewed the variance. The sales variance at one percent was trivial. After talking to the manufacturing vice-president, who was in charge of both plants, you concluded that the mate- corrections. 52 CASE 7: COFFEE MAKER SUPREME/53 EXHIBIT 1: OPERATING STATEMENT, YEAR T (MILLIONS OF DOLLARS) Budget Actual Variance $216.0 $218.3 $ 2.3 Sales Cost of Goods Sold Variable costs: Materials Manufacturing labour Manufacturing overhead Selling 62.7 10.6 23.7 8.6 105.6 64.8 11.4 25.1 8.7 110.0 108.3 (2.1) (0.8) (1.4) (0.1) (4.4) (2.1) 110.4 Contribution Margin Fixed Expenses Manufacturing overhead Selling Administration 49.4 10.7 18.6 78.7 66.1 10.6 18.7 95.4 $ 12.9 (16.7) 0.1 (0.1) (16.7) $(18.8) Operating Income $ 31.7 EXHIBIT 2: COST OF QUALITY REPORT (MILLIONS OF DOLLARS) Year T T-1 T-2 T-3 T-4 T-5 Prevention costs Appraisal costs Internal failure costs External failure costs Total quality costs $ 1.2 0.1 2.1 6.7 $10.1 $3.1 1.3 1.1 0.6 6.1 $3.2 1.4 1.0 0.2 5.8 $3.0 1.2 0.7 0.6 5.5 oleos $2.8 1.0 0.8 0.3 4.9 $2.6 1.0 0.8 0.4 4.8 EXHIBIT 3: CUSTOMER SATISFACTION SURVEY (DECEMBER SURVEYS, % SCORE ON A 0% TO 100% SCALE) Year T T-1 T-2 T-3 T-4 T-5 Product quality Durability Good value Features 61.5 58.3 48.6 88.6 85.5 93.3 75.1 53.8 84.7 92.7 77.5 56.3 85.9 92.2 76.6 55.8 86.1 92.7 78.1 54.7 85.3 93.6 76.4 53.1 rial variance is largely attributed to some yield problems with some materials and components and that these yield problems created the unfavourable variances for direct labour and variable manufac- turing overhead. A bigger problem was the fixed manufacturing overhead. The manufacturing vice- president explained this variance to be the result of charging to fixed manufacturing overhead, the rework required in getting the plants accustomed to manufacturing the new and newly designed prod- ucts. Warranty work was also charged to fixed manufacturing overhead, whether an actual or esti- mated charge. You also asked for and received the cost of quality report (Exhibit 2) and the customer satisfaction survey results (Exhibit 3). Required As the controller, carry out your assign- ment using the case approach. CASE 7 Coffee Maker Supreme ders Coffee Maker Supreme (CMS) has been in the business of manufacturing coffee makers for three generations. During the first and second genera- tions the growth in demand was modestly positive, and customers seemed to have been more content with product range and quality. During the time of the present generation of owners, the demand for coffee machines grew at a much higher rate. That demand does not appear to be declining in the foreseeable future. Moreover, customers have become increasingly demanding of specialized and high-quality coffee makers. CMS is a privately owned manufacturer and distributor of machines to make coffee. Sales are more than $200 million per year. Customers from all parts of world - are restaurants, cafes, and cafeterias. Sales are are made by commissioned sales supported by a website to process and to provide after-sales service. CMS started in the Canadian market, but expanded into the United States a decade before the free-trade agreement. Nicole Roberto joined the business after completing her CMA. Two years earlier, she had completed her undergraduate degree in business. She encouraged her father to purchase coffee machine manufacturers in France and Italy in order to expand into the European market. She then . spent a decade in Europe developing the business. Her heritage language Italian - and her French immersion studies from grades 1 to 12 assisted her in successfully developing the European business. In 1997, the sales representatives from around the world were provided with Web-based sales sup- port for transacting sales and for the customers to obtain post-sales service and support . This system proved highly successful, allowing CMS to further expand into Europe and into the Japanese and Mexican markets. The global reach with plants in Canada, the United States, France and Italy meant that there was a rather haphazard product line. The four plants produced 27 products, of which 10 were literally duplicates of another 10, resulting in only 17 truly different products. In 2000, the product line was rationalized, allowing two of the plants to be closed and for the product line to be increased by 13 new coffee makers that were different from existing products. Of the current 30 different coffee makers, 16 are manufactured in one plant and 14 are manufactured in the other. In effect, the new products expanded both ends of the product linc, i.e., both larger-capacity and small special-purpose coffee makers. Moreover, features were added to make all coffee makers more versatile. In effect, each of the 30 products experienced product design and manufacturing pro- cess changes. Global sourcing was introduced at the same time to ensure procurement of the most appropri ate and cost-effective materials and components. Along with global sourcing, the decades-old prac- tice of 100 percent inspection was replaced with a more modern system of random checks. This allowed for most of the inspectors to be reassigned. Suppliers were responsible for quality of all materi- als and components, and manufacturing workers were responsible for quality control in the manu- facturing process. Each worker knew the operating specifications, and if a unit received at his or her station was not up to standard, the manufactur- ing process could be stopped for the necessary The financial results of the first full year of operations with the product line and related changes are shown in Exhibit 1. These results were what president Nicole Roberto showed you as you started your first day the controller. Nicole had been brought back to Canada three months earlier when the previous president had been obliged to retire for health reasons. The first task assigned to you by Nicole was to determine why, when sales targets were met, operating income was substantially lower than bud- get. You first reviewed the variance. The sales variance at one percent was trivial. After talking to the manufacturing vice-president, who was in charge of both plants, you concluded that the mate- corrections. 52 CASE 7: COFFEE MAKER SUPREME/53 EXHIBIT 1: OPERATING STATEMENT, YEAR T (MILLIONS OF DOLLARS) Budget Actual Variance $216.0 $218.3 $ 2.3 Sales Cost of Goods Sold Variable costs: Materials Manufacturing labour Manufacturing overhead Selling 62.7 10.6 23.7 8.6 105.6 64.8 11.4 25.1 8.7 110.0 108.3 (2.1) (0.8) (1.4) (0.1) (4.4) (2.1) 110.4 Contribution Margin Fixed Expenses Manufacturing overhead Selling Administration 49.4 10.7 18.6 78.7 66.1 10.6 18.7 95.4 $ 12.9 (16.7) 0.1 (0.1) (16.7) $(18.8) Operating Income $ 31.7 EXHIBIT 2: COST OF QUALITY REPORT (MILLIONS OF DOLLARS) Year T T-1 T-2 T-3 T-4 T-5 Prevention costs Appraisal costs Internal failure costs External failure costs Total quality costs $ 1.2 0.1 2.1 6.7 $10.1 $3.1 1.3 1.1 0.6 6.1 $3.2 1.4 1.0 0.2 5.8 $3.0 1.2 0.7 0.6 5.5 oleos $2.8 1.0 0.8 0.3 4.9 $2.6 1.0 0.8 0.4 4.8 EXHIBIT 3: CUSTOMER SATISFACTION SURVEY (DECEMBER SURVEYS, % SCORE ON A 0% TO 100% SCALE) Year T T-1 T-2 T-3 T-4 T-5 Product quality Durability Good value Features 61.5 58.3 48.6 88.6 85.5 93.3 75.1 53.8 84.7 92.7 77.5 56.3 85.9 92.2 76.6 55.8 86.1 92.7 78.1 54.7 85.3 93.6 76.4 53.1 rial variance is largely attributed to some yield problems with some materials and components and that these yield problems created the unfavourable variances for direct labour and variable manufac- turing overhead. A bigger problem was the fixed manufacturing overhead. The manufacturing vice- president explained this variance to be the result of charging to fixed manufacturing overhead, the rework required in getting the plants accustomed to manufacturing the new and newly designed prod- ucts. Warranty work was also charged to fixed manufacturing overhead, whether an actual or esti- mated charge. You also asked for and received the cost of quality report (Exhibit 2) and the customer satisfaction survey results (Exhibit 3). Required As the controller, carry out your assign- ment using the case approach