Question

Case Brief This case study is based on a manufacturing company called FARR Ceramics, headquartered in Dhaka, its factory situated in Gazipur and is directly

Case Brief

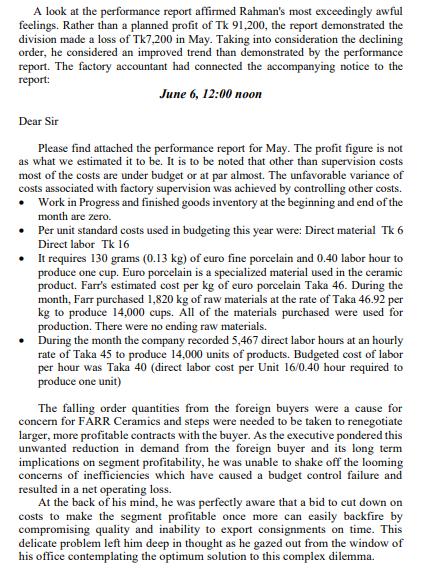

This case study is based on a manufacturing company called FARR Ceramics, headquartered in Dhaka, its factory situated in Gazipur and is directly monitored by the Dhaka head office. The case focuses on a particular order for a certain special type of ceramic cup exported periodically and the issues revolving around delivering orders and keeping costs related issues at bay. Also, the case provides an opportunity to prepare budgets based on real-life cost figures and thereby appreciating the intricate details of Management Accounting.

Learning Objective

After the end of the case, students will be able to

- Calculate per unit variable and fixed cost allocated to production.

- Calculate unit cost of production and shipping

- Prepare flexible budget

- Prepare a flexible budget performance report

- Evaluate a flexible budget performance report

- Compute direct material price and quantity variance

- Compute direct labour rate and efficiency variance

- Prepare a sensitivity analysis

Assignment Questions

- Use the budget data to calculate the per-unit fixed and variable cost allocated to production. What was the actual cost per unit of production and shipping?

- Draft a flexible budget based on the data provided.

- Prepare a flexible budget performance report.

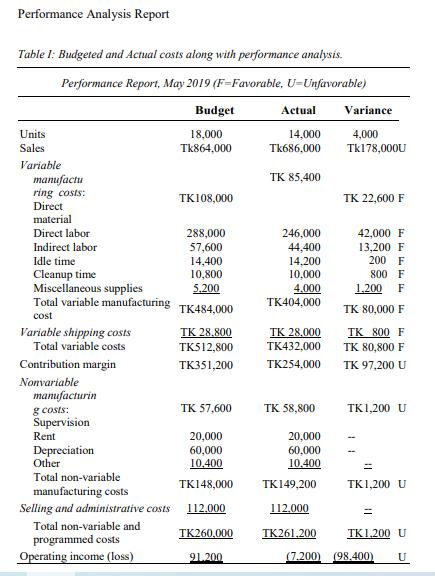

- The factory accountant’s performance analysis report has been presented to Mr. Rahman. Using Table I, comment on the findings. Suggest areas of improvement before it is sent to the head office of FARR ceramics that the manager may like to be reflected in this analysis. (Hints: it might be useful to look into the material price and quantity variances and labor rate and efficiency variances)

- What is the implication on non-variable manufacturing cost if the decline in order by Rosenthal continues? Prepare a sensitivity analysis considering the declining order trend and suggest FARR Ceramics’ possible ways of improving their current performance.

INTRODUCTION This case study is based on a manufacturing company called FARR Ceramics, headquartered in Dhaka, its factory situated in Gazipur and is directly monitored by the Dhaka head office. The case focuses on a particular order for a certain special type of ceramic cup exported periodically and the issues revolving around delivering orders and keeping costs related issues at bay. Also, the case provides an opportunity to prepare budgets based on real- life cost figures and thereby appreciating the intricate details of Management Accounting. PURPOSE The core objective of this case study is to develop analytical problem- solving capabilities within the realm of Management Accounting for the in class students. The case study provides an in-depth opportunity to evaluate how operational issues can affect the costing of orders and prepare budgets incorporating those inconsistencies. Furthermore, students learn to evaluate the impact of certain procedural changes on the costing and budgeting figures. CASE METHODOLOGY The case was designed by interviewing the managers on-site and looking at the prospectus of the company which had an ample amount of information for the particular order discussed in the case below. The production process was observed being physically present on-site and scrutinizing the intricate

Step by Step Solution

3.47 Rating (154 Votes )

There are 3 Steps involved in it

Step: 1

Question 1 Actual unit cost of production 3951 and shipping 2 2 Flexible Budget Units 14000 Sales 672000 Variable Manufacturing Costs Direct Material 84000 Direct Labor 224000 Indirect labor 44800 Idl...

Get Instant Access to Expert-Tailored Solutions

See step-by-step solutions with expert insights and AI powered tools for academic success

Step: 2

Step: 3

Ace Your Homework with AI

Get the answers you need in no time with our AI-driven, step-by-step assistance

Get Started