Question

In the year-ending review meeting called by Mr Akbar , MD, on 15 April 2001, Mr Ali ,General Manager, in charge of logistics, was pulled

In the year-ending review meeting called by Mr Akbar , MD, on 15 April 2001, Mr Ali ,General Manager, in charge of logistics, was pulled up by VP (Finance),who expressed her concern over the increased level of finished goods inventory that was creating cash flow problems. She also made remarks on the prevailing warehouse practices in the company, which were resulting in low productivity and higher warehousing cost. In defense, Ali tried to explain the situation based on the facts and figures he had with him and suggested some measures to overcome the problem.

The Company

Phantom Glass Ltd. is one of the leading glass manufacturing companies having an installed capacity of 32 million CSQM (600 tonnes per day) of float glass. The plant is located in western area at a prime location. The company is manufacturing a variety of international quality glass in technical and financial collaboration with a world-class manufacturer. The capacity utilization was 80 per cent during the last two years. This is much above the other producers of similar products.

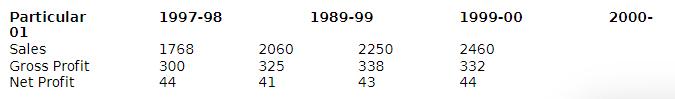

Phantom is making good headway in the market as the products are well accepted because of the world-class quality, and the prices are comparable to other available products in the market. Even in the prevailing recessionary trends in the market, the company registered an increase of 9.3 per cent in sales, similar to what they achieved last year, with the help of which they could maintain their market share at 20 per cent. The financial results for the past four years are shown in below table

Of the total production, 35 per cent is of premium quality glass used in the automobile sector, while the balance 65 per cent goes into other applications. Phantom’s 30 per cent sales are generated through exports. The organization is headed by the Managing Director, assisted by the Vice Presidents, who head the technical, production, marketing, finance and material and logistics operations respectively. The company is marketing its products through a network of four regional offices and 200 dealers.

They have no material storage facilities at the regional level. The material after loading on to the carrier is unloaded at the customer’s or the dealer’s place. All domestic supplies are organized through road carriers.

The Product

Phantom manufactures glass sheets in five different shades and thicknesses for a variety of applications. The sheets are cut according to customer requirements up to a maximum size of 9 ft 3 16 feet. However, the most common size is 4 ft 3 8 ft. The major features of Phantom products are distortion-free and sparkling surface, thickness uniformity, high optical clarity, brilliant images when mirrored and higher strength for handling and usage. The product applications cover window glazing, curtain walls, partition walls, doors, shop fronts, furniture, mirrors, safety glass for automobiles, clocks, and so forth.

Logistics Operations

The logistics operations of PGL are handled by the General Manager , who reports to VP (materials and logistics). The customer service department (CSD) is under the GM—Marketing, who acts in close coordination with the logistics department .The customer requirements are conveyed to the logistics section by the CSD well in advance.

Based on customer orders, the logistics section initiates the dispatch action.

• Coordination with CSD The logistics department acts on the instructions of the CSD for material dispatches and maintains close coordination with them. However, due to delays in getting information on production schedules, the CSD department sometimes cannot give confirmed dispatch schedules to logistics. This results in part loading of the trucks, longer waiting for trucks (thus attracting the penalty), delays in loading and improper utilization of contract labour that are paid on a daily basis.

Load unitization in crates The glass sheets cut into various sizes are unitized in wooden crates. Phantom uses over 100 different sizes of crates for the customized requirement of glass sheet sizes by the customers. They use 10,000 crates per month. However, out of the total crate requirement, 30 per cent fall in size 8 ft 3 4 ft, 20–25 per cent in sizes 16 ft 3 9 ft and 10 ft 3 8 ft, which is reserved for exports. The balance 50 per cent requirement of crates is in odd sizes.

The packaging cost for the domestic consignment is 8 per cent (due to the large number of odd sizes) of product cost, while it is 5 per cent of the product cost for the export consignment.

Allocate the storage space After the glass sheets are packed, the crates are moved to the warehouse for space allocation and storage. The area available for storing the finished goods is 2500 sq meter. The warehouse bay has two overhead cranes of 10 MT capacity each and two forklift trucks of 500 Kgs and 1000 Kgs capacity respectively. The crates are stored in the vertical inclined position. They have special ‘A’ type racks to keep the crates in the vertical inclined position at 95 degrees.

These racks (600 no.) occupy more than 250 sq meter of floor area. As the product is stored in packed form in the crates, the area required for storage is almost 30 per cent more than for bare glass sheets. Due to space constraints in the warehouse, they store 250 CSQM of material per sq meter of warehouse floor space, while the international standard for easy and safe material (glass) storage and movement is 175 CSQM per sq meter of warehouse floor area.

Due to legal constraints and the fragile nature of the product, they cannot plan for a multi-story warehouse building. The order picking operation takes a lot of time due to the over-storage at warehouse. A lot of time is spent in removing the other crates to locate the right material and clear the movement path for the forklift. The breakage rate during material handling in warehouse area is on the higher side due to the congested storage arrangement.

Organize the dispatches The logistics department is also involved in dispatch of the material from factory to various clients. The dispatch instructions are issued by the CSD. The contract labor are used for material movement and loading. The material is dispatched to customers and dealers through road carriers. The material is normally dispatched through tempos (6 tons), trucks (9 tons) and trailers (25 tons).

For the exports consignments, they use 20 ft dry, box-type containers. The material is loaded with the special ‘C’ type clamp developed for easy loading of the glass sheet crates inside the container. Due to lack of coordination between the CSD and the logistics departments, the trucks and the container trailers keep waiting for 2/3 days. The waiting attracts a penalty of Rs. 10,000 for a container trailer and Rs. 5000 for a lorry per day.

The productivity level at the logistics department is very low. In spite of engaging contract workers, they make 2/3 loads per shift as against the norm of 5 loads. They engage 5/6 groups per day to make the loads. Each group consists of five laborer and one supervisor.

Inventory management Inventory management is an integral part of the job responsibility of the warehouse manager. The stock control is manual. The warehouse staff spends much of their time in multiple manual entries. Without bar coding system, the material storage and retrieval takes a lot of time. Material tracking is a tedious task. The warehouse maintains an inventory of over 200 odd sizes (combination of thicknesses, sheet size and colours). Phantom’s marketing policy allows them to supply the material in customized sizes, which contributes to more than the 50 per cent of the company’s sales. The major problem is the inventory of the odd sizes, which at any point of time has more than 60 per cent of the share in value terms. The inventory turnover ratio at Phantom is 3.8, which is quite low as compared to the international standard that is in the range of 6–7.

1. Study the attached case study and answer the following questions.

a.Analyze both internal & external environment of the company and explore 5 biggest reasons of poor performance of the company? 3

b.Can new technological tool be used for performance betterment? If yes, recommend three such practices 3

c. Are the prevalent practices ecofriendly? Does your answer of part(b) enhance eco-performance of company too? 3

2. You want to outsource company transport operations. For this you are finding a competent transport service provider ensuring fast delivery in northern area. What will be your sequence of action for this task? 6

Particular 01 Sales Gross Profit Net Profit 1997-98 1768 300 44 2060 325 41 1989-99 2250 338 43 1999-00 2460 332 44 2000-

Step by Step Solution

3.48 Rating (155 Votes )

There are 3 Steps involved in it

Step: 1

1a Analysis of internal and external environment of the company and the 5 biggest reasons for poor performance Internal Environment Analysis Strengths ...

Get Instant Access to Expert-Tailored Solutions

See step-by-step solutions with expert insights and AI powered tools for academic success

Step: 2

Step: 3

Ace Your Homework with AI

Get the answers you need in no time with our AI-driven, step-by-step assistance

Get Started