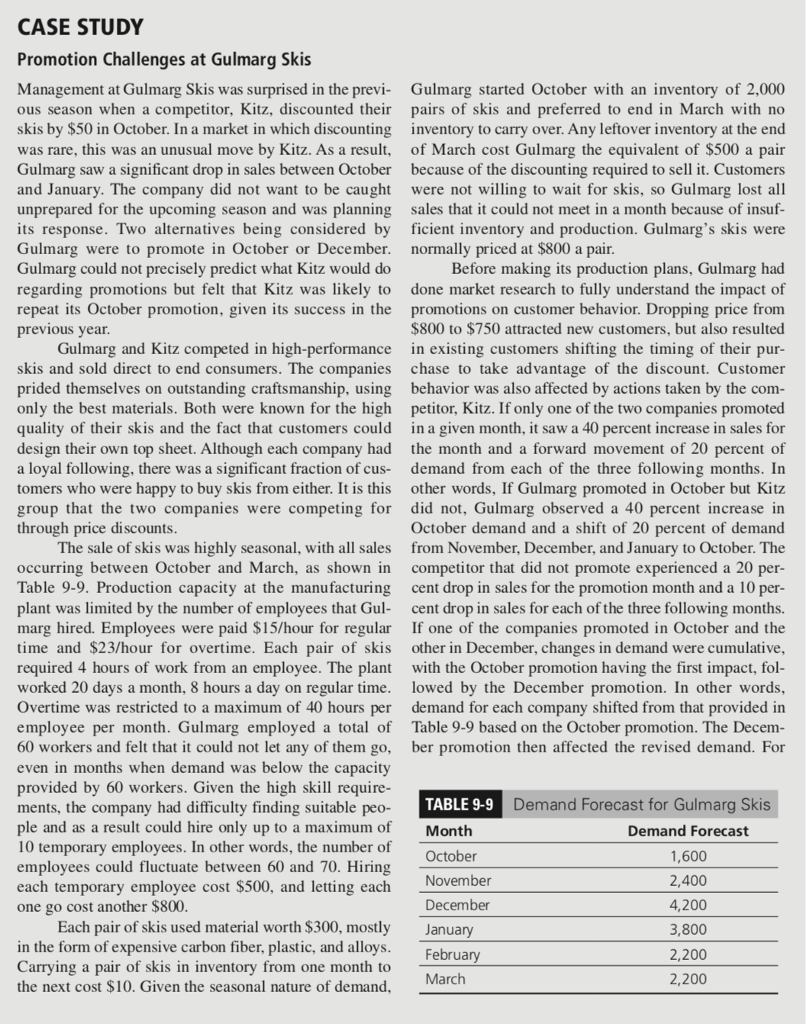

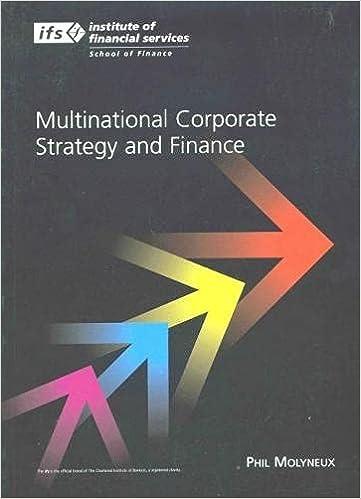

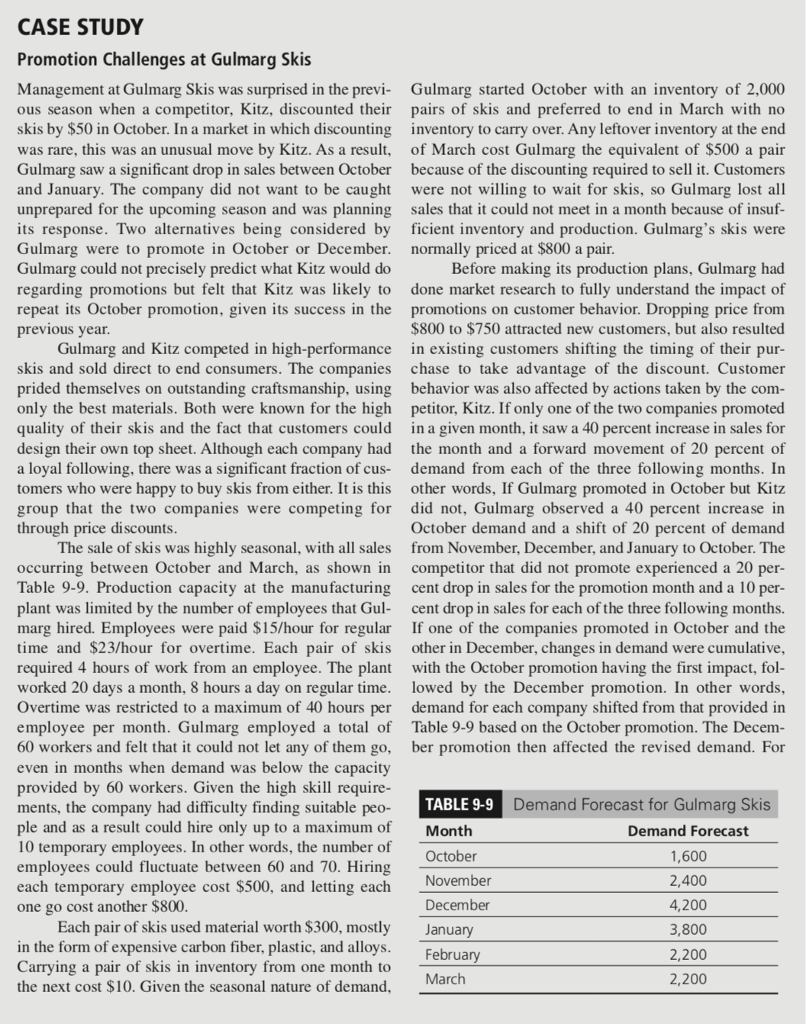

CASE STUDY Promotion Challenges at Gulmarg Skis Management at Gulmarg Skis was surprised in the previ Gulmarg started October with an inventory of 2,000 ous season when a competitor, Kitz, discounted their pairs of skis and preferred to end in March with no skis by $50 in October. In a market in which discounting inventory to carry over. Any leftover inventory at the end was rare, this was an unusual move by Kitz. As a result, of March cost Gulmarg the equivalent of $500 a pair Gulmarg saw a significant drop in sales between October because of the discounting required to sell it. Customers and January. The company did not want to be caught were not willing to wait for skis, so Gulmarg lost all unprepared for the upcoming season and was planning sales that it could not meet in a month because of insuf- its response. Two alternatives being considered by ficient inventory and production. Gulmarg's skis were Gulmarg were to promote in October or December. normally priced at $800 a pair Gulmarg could not precisely predict what Kitz would do regarding promotions but felt that Kitz was likely to done market research to fully understand the impact of repeat its October promotion, given its success in the promotions on customer behavior. Dropping price from previous year Before making its production plans, Gulmarg had $800 to $750 attracted new customers, but also resulted in existing customers shifting the timing of their pur chase to take advantage of the discount. Customer behavior was also affected by actions taken by the com- petitor, Kitz. If only one of the two companies promoted in a given month, it saw a 40 percent increase in sales for the month and a forward movement of 20 percent of demand from each of the three following months. In other words, If Gulmarg promoted in October but Kitz did not, Gulmarg observed a 40 percent increase in October demand and a shift of 20 percent of demand from November, December, and January to October. The Gulmarg and Kitz competed in high-performance skis and sold direct to end consumers. The companies prided themselves on outstanding craftsmanship, using only the best materials. Both were known for the high quality of their skis and the fact that customers could design their own top sheet. Although each company had a loyal following, there was a significant fraction of cus- tomers who were happy to buy skis from either. It is this group that the two companies were competing for through price discounts The sale of skis was highly seasonal, with all sales occurring between October and March, as shown in competitor that did not promote experienced a 20 per Table 9-9. Production capacity at the manufacturing cent drop in sales for the promotion month and a 10 per plant was limited by the number of employees that Gul cent drop in sales for each of the three following months. marg hired. Employees were paid $15/hour for regular If one of the companies promoted in October and the time and $23/hour for overtime. Each pair of skis other in December, changes in demand were cumulative, required 4 hours of work from an employee. The plant with the October promotion having the first impact, fol worked 20 days a month, 8 hours a day on regular time. lowed by the December promotion. In other words, Overtime was restricted to a maximum of 40 hours per demand for each company shifted from that provided in employee per month. Gulmarg employed a total of Table 9-9 based on the October promotion. The Decem 60 workers and felt that it could not let any of them go, ber promotion then affected the revised demand. For even in months when deman provided by 60 workers. Given the high skill require- ments, the company had difficulty finding suitable peo- ple and as a result could hire only up to a maximum of 10 temporary employees. In other words, the number d was below the capacity TABLE 9-9 Demand Forecast for Gulmarg Skis October November December anuary February March Demand Forecast 1,600 2,400 4,200 3,800 2,200 2,200 could fluctuate between 60 and 70. Hiring t $500, and letting each ch temporary emplo e go cost another $800 Each pair of skis used material worth $300, mostly n the form of expensive carbon fiber, plastic, and alloy Carrying a pair of skis in inventory from one month to the next cost $10. Given the seasonal nature of demand CASE STUDY Promotion Challenges at Gulmarg Skis Management at Gulmarg Skis was surprised in the previ Gulmarg started October with an inventory of 2,000 ous season when a competitor, Kitz, discounted their pairs of skis and preferred to end in March with no skis by $50 in October. In a market in which discounting inventory to carry over. Any leftover inventory at the end was rare, this was an unusual move by Kitz. As a result, of March cost Gulmarg the equivalent of $500 a pair Gulmarg saw a significant drop in sales between October because of the discounting required to sell it. Customers and January. The company did not want to be caught were not willing to wait for skis, so Gulmarg lost all unprepared for the upcoming season and was planning sales that it could not meet in a month because of insuf- its response. Two alternatives being considered by ficient inventory and production. Gulmarg's skis were Gulmarg were to promote in October or December. normally priced at $800 a pair Gulmarg could not precisely predict what Kitz would do regarding promotions but felt that Kitz was likely to done market research to fully understand the impact of repeat its October promotion, given its success in the promotions on customer behavior. Dropping price from previous year Before making its production plans, Gulmarg had $800 to $750 attracted new customers, but also resulted in existing customers shifting the timing of their pur chase to take advantage of the discount. Customer behavior was also affected by actions taken by the com- petitor, Kitz. If only one of the two companies promoted in a given month, it saw a 40 percent increase in sales for the month and a forward movement of 20 percent of demand from each of the three following months. In other words, If Gulmarg promoted in October but Kitz did not, Gulmarg observed a 40 percent increase in October demand and a shift of 20 percent of demand from November, December, and January to October. The Gulmarg and Kitz competed in high-performance skis and sold direct to end consumers. The companies prided themselves on outstanding craftsmanship, using only the best materials. Both were known for the high quality of their skis and the fact that customers could design their own top sheet. Although each company had a loyal following, there was a significant fraction of cus- tomers who were happy to buy skis from either. It is this group that the two companies were competing for through price discounts The sale of skis was highly seasonal, with all sales occurring between October and March, as shown in competitor that did not promote experienced a 20 per Table 9-9. Production capacity at the manufacturing cent drop in sales for the promotion month and a 10 per plant was limited by the number of employees that Gul cent drop in sales for each of the three following months. marg hired. Employees were paid $15/hour for regular If one of the companies promoted in October and the time and $23/hour for overtime. Each pair of skis other in December, changes in demand were cumulative, required 4 hours of work from an employee. The plant with the October promotion having the first impact, fol worked 20 days a month, 8 hours a day on regular time. lowed by the December promotion. In other words, Overtime was restricted to a maximum of 40 hours per demand for each company shifted from that provided in employee per month. Gulmarg employed a total of Table 9-9 based on the October promotion. The Decem 60 workers and felt that it could not let any of them go, ber promotion then affected the revised demand. For even in months when deman provided by 60 workers. Given the high skill require- ments, the company had difficulty finding suitable peo- ple and as a result could hire only up to a maximum of 10 temporary employees. In other words, the number d was below the capacity TABLE 9-9 Demand Forecast for Gulmarg Skis October November December anuary February March Demand Forecast 1,600 2,400 4,200 3,800 2,200 2,200 could fluctuate between 60 and 70. Hiring t $500, and letting each ch temporary emplo e go cost another $800 Each pair of skis used material worth $300, mostly n the form of expensive carbon fiber, plastic, and alloy Carrying a pair of skis in inventory from one month to the next cost $10. Given the seasonal nature of demand