Question: Case study: Safe pressure vessels that leak before break You wish to design a thin - walled spherical pressure vessel of known radius R ,

Case study: Safe pressure vessels that "leak before break"

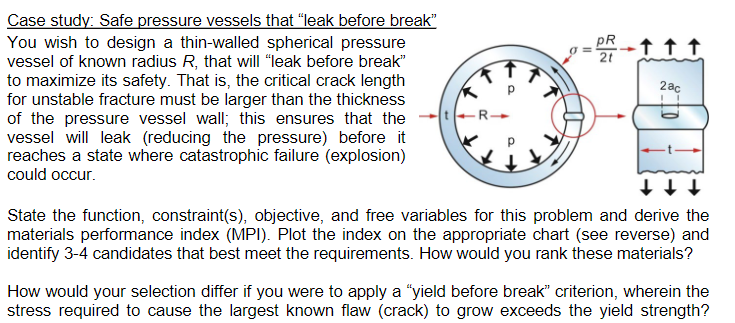

You wish to design a thinwalled spherical pressure

vessel of known radius that will "leak before break"

to maximize its safety. That is the critical crack length

for unstable fracture must be larger than the thickness

of the pressure vessel wall; this ensures that the

vessel will leak reducing the pressure before it

reaches a state where catastrophic failure explosion

could occur.

State the function, constraints objective, and free variables for this problem and derive the

materials performance index MPI Plot the index on the appropriate chart see reverse and

identify candidates that best meet the requirements. How would you rank these materials?

How would your selection differ if you were to apply a "yield before break" criterion, wherein the

stress required to cause the largest known flaw crack to grow exceeds the yield strength?

I am having trouble deriving the MPI, if someone could walk me through the steps that would be great!

Step by Step Solution

There are 3 Steps involved in it

1 Expert Approved Answer

Step: 1 Unlock

Question Has Been Solved by an Expert!

Get step-by-step solutions from verified subject matter experts

Step: 2 Unlock

Step: 3 Unlock