Question: [CASE STUDY TRAFALGAR BRIDGE] Read the Case attached carefully and answer the following Questions i. Critically analyze the costs of all alternatives for the Trafalgar

![[CASE STUDY TRAFALGAR BRIDGE] Read the Case attached carefully and answer the](https://dsd5zvtm8ll6.cloudfront.net/si.experts.images/questions/2024/10/6702545a33972_9136702545975691.jpg)

[CASE STUDY TRAFALGAR BRIDGE] Read the Case attached carefully and answer the following Questions

[CASE STUDY TRAFALGAR BRIDGE] Read the Case attached carefully and answer the following Questions

i. Critically analyze the costs of all alternatives for the Trafalgar Bridge. (35 marks)

ii. As Bentley Eghoetz, what would be your recommendation(s) (5 marks)

EXPERTS KINDLY ASSIST US WITH THE SOLUTIONS TO THIS CASE STUDY PROVIDED ALREADY AS SEEN IN THE IMAGE. DEADLINE IS ON MONDAY. THANKS

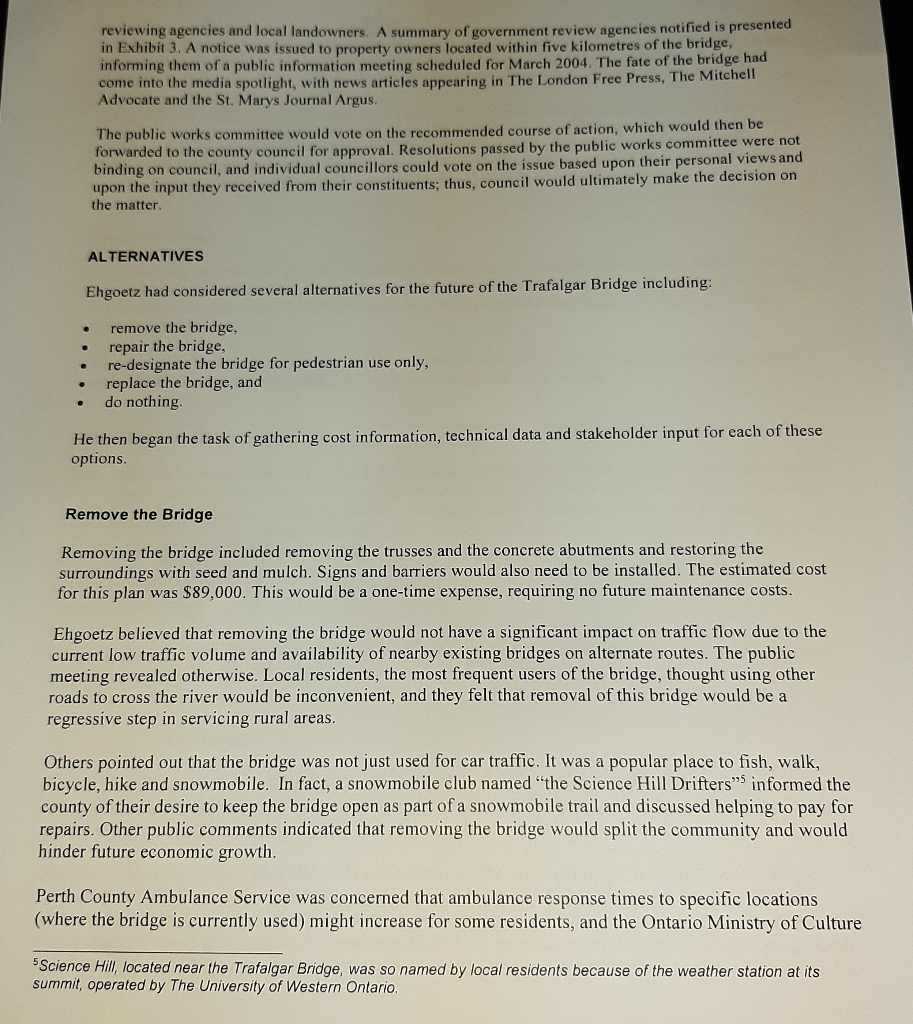

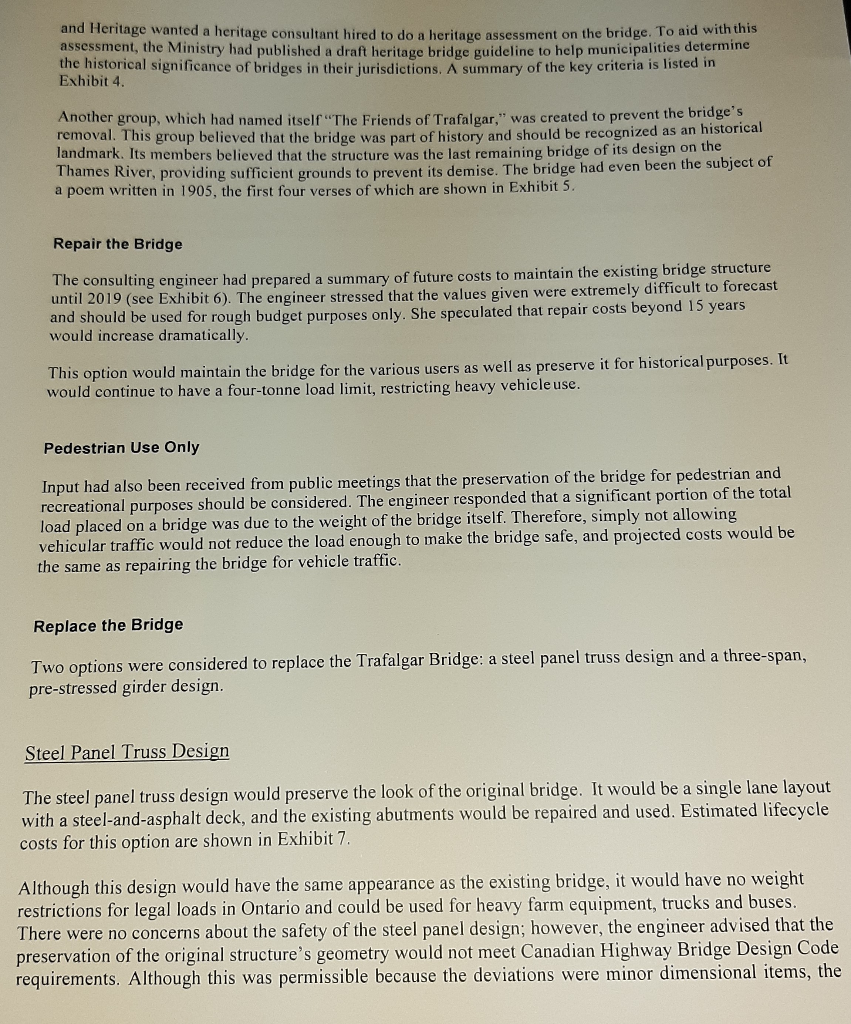

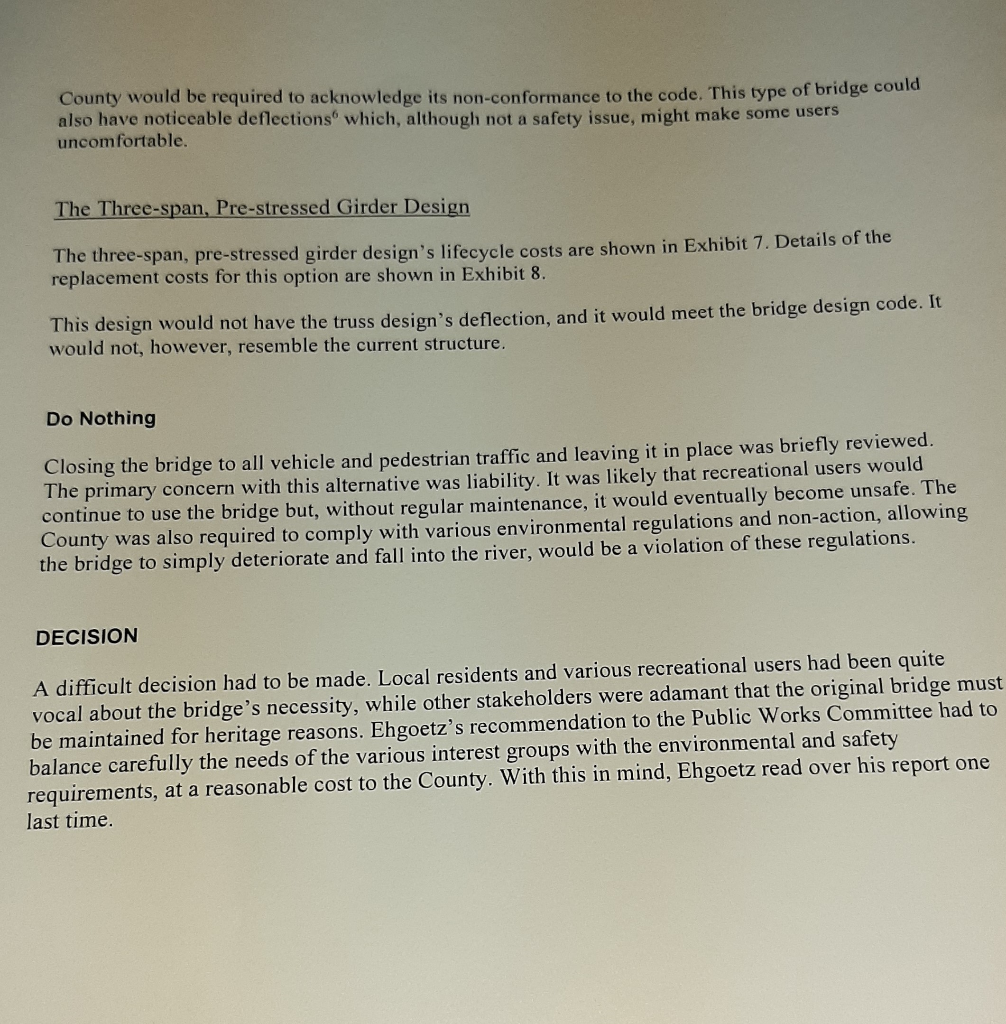

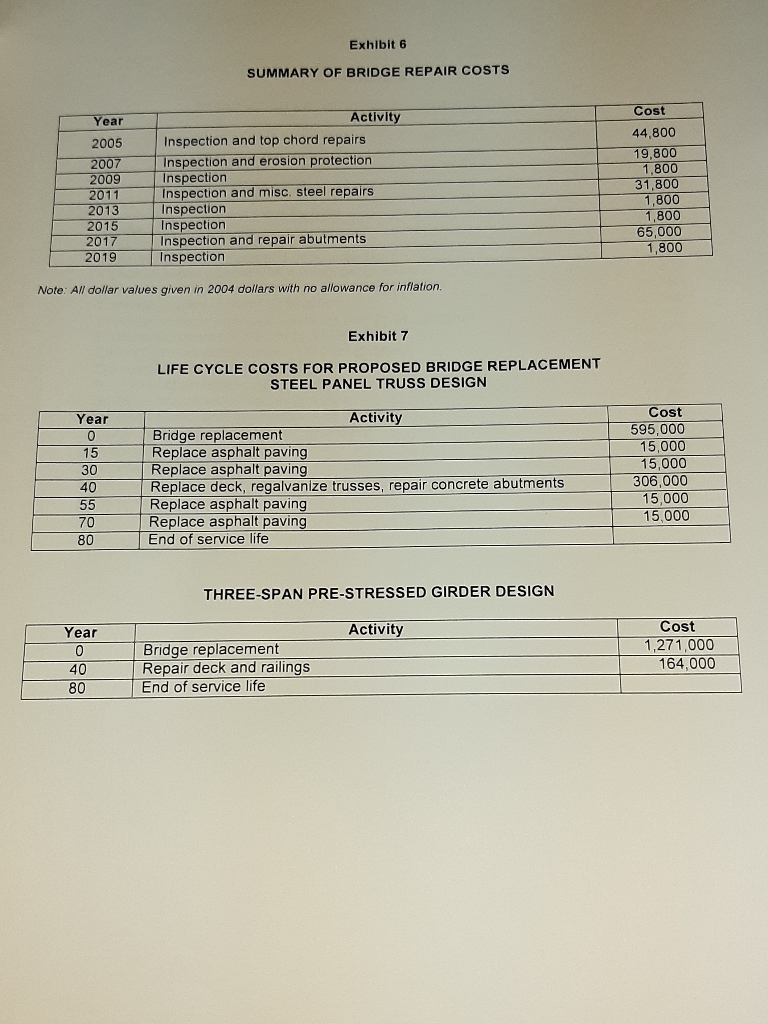

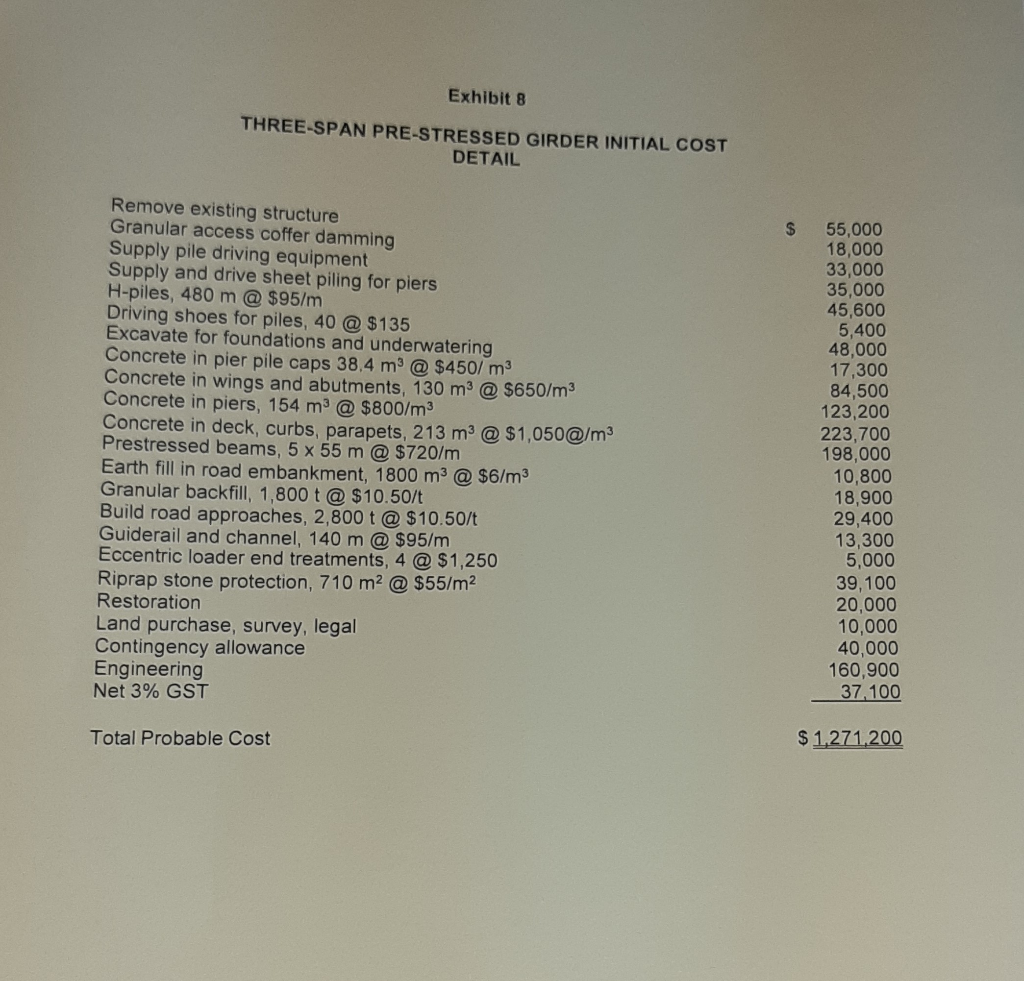

THE TRAFALGAR BRIDGE History The Trafalgar Bridge, built in 1905, was named after the famous naval battle fought one hundred years earlier (see Exhibit 1). It was located approximately seven kilometres north of St. Marys on Line 12 a gravel-surfaced road (see Exhibit 2). The bridge was a pin-connected, steel truss design that crossed the Thames River. The span of the bridge was 42.2 metres, and its width was 4.35 metres, allowing only a single lane of traffic. The load limit of the bridge was restricted to four tonnes. Traffic volume was approximately 110 vehicles per day and consisted of cars and light farm equipment. The load limit prevented heavy farm equipment and trucks from using the bridge. Newer bridges crossing the river at Line 10 and Line 16, approximately two kilometres away from the Trafalgar Bridge, had to be used by these heavier vehicles (see Exhibit 2). Maintenance The bridge had recently gone through a series of repairs. Over the past four years, regular engineering inspections had been done each year at a cost of $1,500 per annum. Repair work to the bridge had cost the county $35,000 over the same time period. The most recent inspections, performed by a consulting engineering firm in February 2004, had identified significant problems with the structural integrity of the bridge. The consulting engineer suggested that repairs might not be practical given the anticipated costs, low traffic volumes and the availability of two alternate routes. Consultations Faced with this information, Ehgoetz began preparing possible courses of action to present to the public works committee. This 10-person committee was composed of county councillors. Ehgoetz needed to determine cost and technical data and gather input from the various stakeholders, including government Operating budgets are intended for day-to-day expenses with planning periods of one year or less. Capital budgets incorporate major expenditures for equipment and infrastructure and often have planning periods of five to 10 years. *The battle of Trafalgar took place in 1805 when the French and Spanish naval fleets sent by Napoleon engaged the British fleet off the coast of Spain. The English, under the command of Lord Horatio Nelson aboard HMS Victory, decisively won the battle, however, Nelson was shot and killed by a French marksman reviewing agencies and local landowners. A summary of government review agencies notified is presented in Exhibit 3. A notice was issued to property owners located within five kilometres of the bridge, informing them of a public information meeting scheduled for March 2004. The fate of the bridge had come into the media spotlight, with news articles appearing in The London Free Press, The Mitchell Advocate and the St. Marys Journal Argus. The public works committee would vote on the recommended course of action, which would then be forwarded to the county council for approval. Resolutions passed by the public works committee were not binding on council, and individual councillors could vote on the issue based upon their personal views and upon the input they received from their constituents; thus, council would ultimately make the decision on the matter ALTERNATIVES Ehgoetz had considered several alternatives for the future of the Trafalgar Bridge including: . remove the bridge, repair the bridge, re-designate the bridge for pedestrian use only, replace the bridge, and do nothing He then began the task of gathering cost information, technical data and stakeholder input for each of these options. Remove the Bridge Removing the bridge included removing the trusses and the concrete abutments and restoring the surroundings with seed and mulch. Signs and barriers would also need to be installed. The estimated cost for this plan was $89,000. This would be a one-time expense, requiring no future maintenance costs. Ehgoetz believed that removing the bridge would not have a significant impact on traffic flow due to the current low traffic volume and availability of nearby existing bridges on alternate routes. The public meeting revealed otherwise. Local residents, the most frequent users of the bridge, thought using other roads to cross the river would be inconvenient, and they felt that removal of this bridge would be a regressive step in servicing rural areas. Others pointed out that the bridge was not just used for car traffic. It was a popular place to fish, walk, bicycle, hike and snowmobile. In fact, a snowmobile club named "the Science Hill Drifters" informed the county of their desire to keep the bridge open as part of a snowmobile trail and discussed helping to pay for repairs. Other public comments indicated that removing the bridge would split the community and would hinder future economic growth. Perth County Ambulance Service was concerned that ambulance response times to specific locations (where the bridge is currently used) might increase for some residents, and the Ontario Ministry of Culture 5Science Hill, located near the Trafalgar Bridge, was so named by local residents because of the weather station at its summit, operated by The University of Western Ontario, and Heritage wanted a heritage consultant hired to do a heritage assessment on the bridge. To aid with this assessment, the Ministry had published a draft heritage bridge guideline to help municipalities determine the historical significance of bridges in their jurisdictions. A summary of the key criteria is listed in Exhibit 4. Another group, which had named itself "The Friends of Trafalgar," was created to prevent the bridge's removal. This group believed that the bridge was part of history and should be recognized as an historical landmark. Its members believed that the structure was the last remaining bridge of its design on the Thames River, providing sufficient grounds to prevent its demise. The bridge had even been the subject of a poem written in 1905, the first four verses of which are shown in Exhibit 5. Repair the Bridge The consulting engineer had prepared a summary of future costs to maintain the existing bridge structure until 2019 (see Exhibit 6). The engineer stressed that the values given were extremely difficult to forecast and should be used for rough budget purposes only. She speculated that repair costs beyond 15 years would increase dramatically. This option would maintain the bridge for the various users as well as preserve it for historical purposes. It would continue to have a four-tonne load limit, restricting heavy vehicle use. Pedestrian Use Only Input had also been received from public meetings that the preservation of the bridge for pedestrian and recreational purposes should be considered. The engineer responded that a significant portion of the total load placed on a bridge was due to the weight of the bridge itself. Therefore, simply not allowing vehicular traffic would not reduce the load enough to make the bridge safe, and projected costs would be the same as repairing the bridge for vehicle traffic. Replace the Bridge Two options were considered to replace the Trafalgar Bridge: a steel panel truss design and a three-span, pre-stressed girder design. Steel Panel Truss Design The steel panel truss design would preserve the look of the original bridge. It would be a single lane layout with a steel-and-asphalt deck, and the existing abutments would be repaired and used. Estimated lifecycle costs for this option are shown in Exhibit 7. Although this design would have the same appearance as the existing bridge, it would have no weight restrictions for legal loads in Ontario and could be used for heavy farm equipment, trucks and buses. There were no concerns about the safety of the steel panel design; however, the engineer advised that the preservation of the original structure's geometry would not meet Canadian Highway Bridge Design Code requirements. Although this was permissible because the deviations were minor dimensional items, the County would be required to acknowledge its non-conformance to the code. This type of bridge could also have noticeable deflections which, although not a safety issue, might make some users uncomfortable. The Three-span, Pre-stressed Girder Design The three-span, pre-stressed girder design's lifecycle costs are shown in Exhibit 7. Details of the replacement costs for this option are shown in Exhibit 8. This design would not have the truss design's deflection, and it would meet the bridge design code. It would not, however, resemble the current structure. Do Nothing Closing the bridge to all vehicle and pedestrian traffic and leaving it in place was briefly reviewed. The primary concern with this alternative was liability. It was likely that recreational users would continue to use the bridge but, without regular maintenance, it would eventually become unsafe. The County was also required to comply with various environmental regulations and non-action, allowing the bridge to simply deteriorate and fall into the river, would be a violation of these regulations. DECISION A difficult decision had to be made. Local residents and various recreational users had been quite vocal about the bridge's necessity, while other stakeholders were adamant that the original bridge must be maintained for heritage reasons. Ehgoetz's recommendation to the Public Works Committee had to balance carefully the needs of the various interest groups with the environmental and safety requirements, at a reasonable cost to the County. With this in mind, Ehgoetz read over his report one last time. Exhibit 6 SUMMARY OF BRIDGE REPAIR COSTS Cost Year 2005 2007 2009 2011 2013 2015 2017 2019 Activity Inspection and top chord repairs Inspection and erosion protection Inspection Inspection and misc, steel repairs Inspection Inspection Inspection and repair abutments Inspection 44,800 19,800 1,800 31,800 1,800 1,800 65,000 1,800 Note: All dollar values given in 2004 dollars with no allowance for inflation Exhibit 7 LIFE CYCLE COSTS FOR PROPOSED BRIDGE REPLACEMENT STEEL PANEL TRUSS DESIGN Year 0 15 30 40 55 70 80 Activity Bridge replacement Replace asphalt paving Replace asphalt paving Replace deck, regalvanize trusses, repair concrete abutments Replace asphalt paving Replace asphalt paving End of service life Cost 595,000 15,000 15,000 306,000 15,000 15.000 THREE-SPAN PRE-STRESSED GIRDER DESIGN Activity Year 0 40 80 Bridge replacement Repair deck and railings End of service life Cost 1,271,000 164,000 Exhibit 8 THREE-SPAN PRE-STRESSED GIRDER INITIAL COST DETAIL $ Remove existing structure Granular access coffer damming Supply pile driving equipment Supply and drive sheet piling for piers H-piles, 480 m @ $95/m Driving shoes for piles, 40 @ $135 Excavate for foundations and underwatering Concrete in pier pile caps 38.4 m @ $450/ m3 Concrete in wings and abutments, 130 m @ $650/m3 Concrete in piers, 154 m @ $800/m3 Concrete in deck, curbs, parapets, 213 m @ $1,050@/m Prestressed beams, 5 x 55 m @ $720/m Earth fill in road embankment, 1800 m3 @ $6/m3 Granular backfill, 1,800 t @ $10.50/t Build road approaches, 2,800 t @ $10.50/t Guiderail and channel, 140 m @ $95/m Eccentric loader end treatments, 4 @ $1,250 Riprap stone protection, 710 m2 @ $55/m2 Restoration Land purchase, survey, legal Contingency allowance Engineering Net 3% GST 55,000 18,000 33,000 35,000 45,600 5,400 48,000 17,300 84,500 123,200 223,700 198,000 10,800 18,900 29,400 13,300 5,000 39,100 20,000 10,000 40,000 160.900 37.100 Total Probable Cost $ 1,271,200 THE TRAFALGAR BRIDGE History The Trafalgar Bridge, built in 1905, was named after the famous naval battle fought one hundred years earlier (see Exhibit 1). It was located approximately seven kilometres north of St. Marys on Line 12 a gravel-surfaced road (see Exhibit 2). The bridge was a pin-connected, steel truss design that crossed the Thames River. The span of the bridge was 42.2 metres, and its width was 4.35 metres, allowing only a single lane of traffic. The load limit of the bridge was restricted to four tonnes. Traffic volume was approximately 110 vehicles per day and consisted of cars and light farm equipment. The load limit prevented heavy farm equipment and trucks from using the bridge. Newer bridges crossing the river at Line 10 and Line 16, approximately two kilometres away from the Trafalgar Bridge, had to be used by these heavier vehicles (see Exhibit 2). Maintenance The bridge had recently gone through a series of repairs. Over the past four years, regular engineering inspections had been done each year at a cost of $1,500 per annum. Repair work to the bridge had cost the county $35,000 over the same time period. The most recent inspections, performed by a consulting engineering firm in February 2004, had identified significant problems with the structural integrity of the bridge. The consulting engineer suggested that repairs might not be practical given the anticipated costs, low traffic volumes and the availability of two alternate routes. Consultations Faced with this information, Ehgoetz began preparing possible courses of action to present to the public works committee. This 10-person committee was composed of county councillors. Ehgoetz needed to determine cost and technical data and gather input from the various stakeholders, including government Operating budgets are intended for day-to-day expenses with planning periods of one year or less. Capital budgets incorporate major expenditures for equipment and infrastructure and often have planning periods of five to 10 years. *The battle of Trafalgar took place in 1805 when the French and Spanish naval fleets sent by Napoleon engaged the British fleet off the coast of Spain. The English, under the command of Lord Horatio Nelson aboard HMS Victory, decisively won the battle, however, Nelson was shot and killed by a French marksman reviewing agencies and local landowners. A summary of government review agencies notified is presented in Exhibit 3. A notice was issued to property owners located within five kilometres of the bridge, informing them of a public information meeting scheduled for March 2004. The fate of the bridge had come into the media spotlight, with news articles appearing in The London Free Press, The Mitchell Advocate and the St. Marys Journal Argus. The public works committee would vote on the recommended course of action, which would then be forwarded to the county council for approval. Resolutions passed by the public works committee were not binding on council, and individual councillors could vote on the issue based upon their personal views and upon the input they received from their constituents; thus, council would ultimately make the decision on the matter ALTERNATIVES Ehgoetz had considered several alternatives for the future of the Trafalgar Bridge including: . remove the bridge, repair the bridge, re-designate the bridge for pedestrian use only, replace the bridge, and do nothing He then began the task of gathering cost information, technical data and stakeholder input for each of these options. Remove the Bridge Removing the bridge included removing the trusses and the concrete abutments and restoring the surroundings with seed and mulch. Signs and barriers would also need to be installed. The estimated cost for this plan was $89,000. This would be a one-time expense, requiring no future maintenance costs. Ehgoetz believed that removing the bridge would not have a significant impact on traffic flow due to the current low traffic volume and availability of nearby existing bridges on alternate routes. The public meeting revealed otherwise. Local residents, the most frequent users of the bridge, thought using other roads to cross the river would be inconvenient, and they felt that removal of this bridge would be a regressive step in servicing rural areas. Others pointed out that the bridge was not just used for car traffic. It was a popular place to fish, walk, bicycle, hike and snowmobile. In fact, a snowmobile club named "the Science Hill Drifters" informed the county of their desire to keep the bridge open as part of a snowmobile trail and discussed helping to pay for repairs. Other public comments indicated that removing the bridge would split the community and would hinder future economic growth. Perth County Ambulance Service was concerned that ambulance response times to specific locations (where the bridge is currently used) might increase for some residents, and the Ontario Ministry of Culture 5Science Hill, located near the Trafalgar Bridge, was so named by local residents because of the weather station at its summit, operated by The University of Western Ontario, and Heritage wanted a heritage consultant hired to do a heritage assessment on the bridge. To aid with this assessment, the Ministry had published a draft heritage bridge guideline to help municipalities determine the historical significance of bridges in their jurisdictions. A summary of the key criteria is listed in Exhibit 4. Another group, which had named itself "The Friends of Trafalgar," was created to prevent the bridge's removal. This group believed that the bridge was part of history and should be recognized as an historical landmark. Its members believed that the structure was the last remaining bridge of its design on the Thames River, providing sufficient grounds to prevent its demise. The bridge had even been the subject of a poem written in 1905, the first four verses of which are shown in Exhibit 5. Repair the Bridge The consulting engineer had prepared a summary of future costs to maintain the existing bridge structure until 2019 (see Exhibit 6). The engineer stressed that the values given were extremely difficult to forecast and should be used for rough budget purposes only. She speculated that repair costs beyond 15 years would increase dramatically. This option would maintain the bridge for the various users as well as preserve it for historical purposes. It would continue to have a four-tonne load limit, restricting heavy vehicle use. Pedestrian Use Only Input had also been received from public meetings that the preservation of the bridge for pedestrian and recreational purposes should be considered. The engineer responded that a significant portion of the total load placed on a bridge was due to the weight of the bridge itself. Therefore, simply not allowing vehicular traffic would not reduce the load enough to make the bridge safe, and projected costs would be the same as repairing the bridge for vehicle traffic. Replace the Bridge Two options were considered to replace the Trafalgar Bridge: a steel panel truss design and a three-span, pre-stressed girder design. Steel Panel Truss Design The steel panel truss design would preserve the look of the original bridge. It would be a single lane layout with a steel-and-asphalt deck, and the existing abutments would be repaired and used. Estimated lifecycle costs for this option are shown in Exhibit 7. Although this design would have the same appearance as the existing bridge, it would have no weight restrictions for legal loads in Ontario and could be used for heavy farm equipment, trucks and buses. There were no concerns about the safety of the steel panel design; however, the engineer advised that the preservation of the original structure's geometry would not meet Canadian Highway Bridge Design Code requirements. Although this was permissible because the deviations were minor dimensional items, the County would be required to acknowledge its non-conformance to the code. This type of bridge could also have noticeable deflections which, although not a safety issue, might make some users uncomfortable. The Three-span, Pre-stressed Girder Design The three-span, pre-stressed girder design's lifecycle costs are shown in Exhibit 7. Details of the replacement costs for this option are shown in Exhibit 8. This design would not have the truss design's deflection, and it would meet the bridge design code. It would not, however, resemble the current structure. Do Nothing Closing the bridge to all vehicle and pedestrian traffic and leaving it in place was briefly reviewed. The primary concern with this alternative was liability. It was likely that recreational users would continue to use the bridge but, without regular maintenance, it would eventually become unsafe. The County was also required to comply with various environmental regulations and non-action, allowing the bridge to simply deteriorate and fall into the river, would be a violation of these regulations. DECISION A difficult decision had to be made. Local residents and various recreational users had been quite vocal about the bridge's necessity, while other stakeholders were adamant that the original bridge must be maintained for heritage reasons. Ehgoetz's recommendation to the Public Works Committee had to balance carefully the needs of the various interest groups with the environmental and safety requirements, at a reasonable cost to the County. With this in mind, Ehgoetz read over his report one last time. Exhibit 6 SUMMARY OF BRIDGE REPAIR COSTS Cost Year 2005 2007 2009 2011 2013 2015 2017 2019 Activity Inspection and top chord repairs Inspection and erosion protection Inspection Inspection and misc, steel repairs Inspection Inspection Inspection and repair abutments Inspection 44,800 19,800 1,800 31,800 1,800 1,800 65,000 1,800 Note: All dollar values given in 2004 dollars with no allowance for inflation Exhibit 7 LIFE CYCLE COSTS FOR PROPOSED BRIDGE REPLACEMENT STEEL PANEL TRUSS DESIGN Year 0 15 30 40 55 70 80 Activity Bridge replacement Replace asphalt paving Replace asphalt paving Replace deck, regalvanize trusses, repair concrete abutments Replace asphalt paving Replace asphalt paving End of service life Cost 595,000 15,000 15,000 306,000 15,000 15.000 THREE-SPAN PRE-STRESSED GIRDER DESIGN Activity Year 0 40 80 Bridge replacement Repair deck and railings End of service life Cost 1,271,000 164,000 Exhibit 8 THREE-SPAN PRE-STRESSED GIRDER INITIAL COST DETAIL $ Remove existing structure Granular access coffer damming Supply pile driving equipment Supply and drive sheet piling for piers H-piles, 480 m @ $95/m Driving shoes for piles, 40 @ $135 Excavate for foundations and underwatering Concrete in pier pile caps 38.4 m @ $450/ m3 Concrete in wings and abutments, 130 m @ $650/m3 Concrete in piers, 154 m @ $800/m3 Concrete in deck, curbs, parapets, 213 m @ $1,050@/m Prestressed beams, 5 x 55 m @ $720/m Earth fill in road embankment, 1800 m3 @ $6/m3 Granular backfill, 1,800 t @ $10.50/t Build road approaches, 2,800 t @ $10.50/t Guiderail and channel, 140 m @ $95/m Eccentric loader end treatments, 4 @ $1,250 Riprap stone protection, 710 m2 @ $55/m2 Restoration Land purchase, survey, legal Contingency allowance Engineering Net 3% GST 55,000 18,000 33,000 35,000 45,600 5,400 48,000 17,300 84,500 123,200 223,700 198,000 10,800 18,900 29,400 13,300 5,000 39,100 20,000 10,000 40,000 160.900 37.100 Total Probable Cost $ 1,271,200

Step by Step Solution

There are 3 Steps involved in it

Get step-by-step solutions from verified subject matter experts