Question

Company Z has the following historical information about sales for one of its hydraulic pump models. On the other hand, the manufacturing process used by

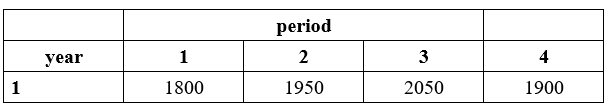

Company Z has the following historical information about sales for one of its hydraulic pump models.

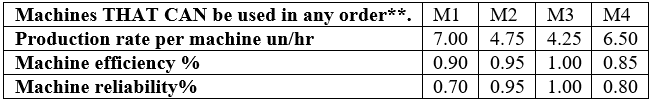

On the other hand, the manufacturing process used by Company Z is sequential* and has the following characteristics:

On the other hand, the manufacturing process used by Company Z is sequential* and has the following characteristics:

* Sequential; in the sense that the output of Mi is the input of Mi+1. ** In any order; in the sense that they can be interchanged, e.g. MA -> MB or MB -> MA.

The company's operating costs are as follows:

Cost per final unit produced "defect free": $100

Cost per final unit produced "with defects": $150

Cost per excess inventory (units "free of defects"): $50

Cost per inventory shortage ("defect free" units): $200

Revenue per final "defect free" unit produced and sold: $250

We have the following operating conditions:

- Any sequence of 3 machines can be used. - Only one machine can be used once, within the same sequence of machines. - You can work UP TO 720 hours per month. - A "level production" type production strategy is followed.

-------------------------------------------------------------------------------------

WHAT NEEDS TO BE DONE: Establish the 1st and 2nd best machine sequence that allows company Z to obtain higher profits (profit = total revenue - total costs) for a hypothetical 5th year.

In both cases PROVE that both sequences meet the requirements of being the 1st and 2nd best sequences.

Note: (a tip)

Do it in excel

-Leveled production

period 2 year 1 3 4 1 1800 1950 2050 1900 Machines THAT CAN be used in any order**. Production rate per machine un/hr Machine efficiency % Machine reliability% M1 7.00 0.90 0.70 M2 M3 M4 4.75 4.25 6.50 0.95 1.00 0.85 0.95 1.00 0.80

Step by Step Solution

There are 3 Steps involved in it

Step: 1

Get Instant Access to Expert-Tailored Solutions

See step-by-step solutions with expert insights and AI powered tools for academic success

Step: 2

Step: 3

Ace Your Homework with AI

Get the answers you need in no time with our AI-driven, step-by-step assistance

Get Started