Answered step by step

Verified Expert Solution

Question

1 Approved Answer

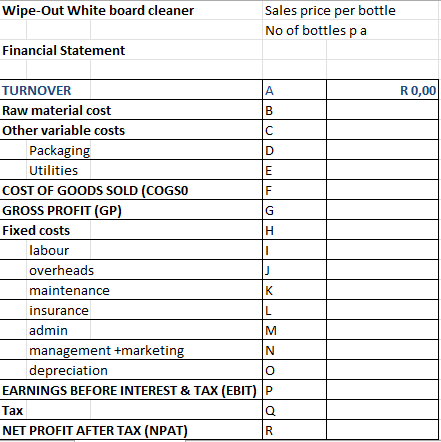

Complete the costing sheet provided for WipeOut and determine the cost to manufacture a bottle of product. Final Product - A 150ml plastic squeeze bottle

Complete the costing sheet provided for WipeOut and determine the cost to manufacture a bottle of product.

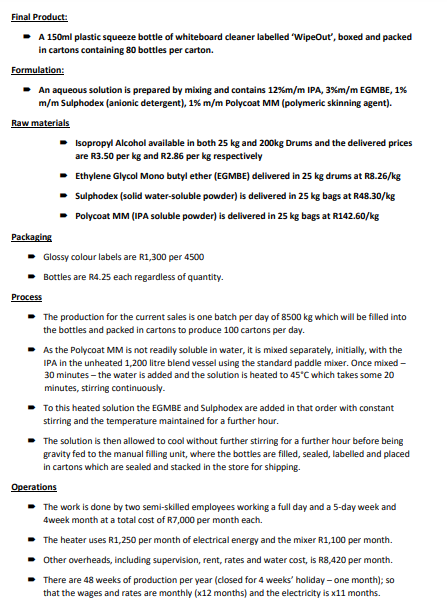

Final Product - A 150ml plastic squeeze bottle of whiteboard cleaner labelled 'WipeOut', boxed and packed in cartons containing 80 bottles per carton. Formulation: - An aqueous solution is prepared by mixing and contains 12%m/m IPA, 3%m/mEGMBE,1% m/m Sulphodex (anionic detergent), 1%m/m Polycoat MM (polymeric skinning agent). Raw materials - Isopropyl Alcohol available in both 25kg and 200kg Drums and the delivered prices are R3.50 per kg and R2.86 per kg respectively - Ethylene Glycol Mono butyl ether (EGMBE) delivered in 25kg drums at R8.26/kg - Sulphodex (solid water-soluble powder) is delivered in 25kg bags at R48.30/kg - Polycoat MM (IPA soluble powder) is delivered in 25kg bags at R142.60/kg Packaging - Glossy colour labels are R1,300 per 4500 - Bottles are R4.25 each regardless of quantity. Process - The production for the current sales is one batch per day of 8500kg which will be filled into the bottles and packed in cartons to produce 100 cartons per day. - As the Polycoat MM is not readily soluble in water, it is mixed separately, initially, with the IPA in the unheated 1,200 litre blend vessel using the standard paddle mixer. Once mixed 30 minutes - the water is added and the solution is heated to 45C which takes some 20 minutes, stirring continuously- - To this heated solution the EGMBE and Sulphodex are added in that order with constant stirring and the temperature maintained for a further hour. - The solution is then allowed to cool without further stirring for a further hour before being gravity fed to the manual filling unit, where the bottles are filled, sealed, labelled and placed in cartons which are sealed and stacked in the store for shipping. Operations - The work is done by two semi-skilled employees working a full day and a 5-day week and 4week month at a total cost of R7,000 per month each. - The heater uses R1,250 per month of electrical energy and the mixer R1,100 per month. - Other overheads, including supervision, rent, rates and water cost, is 28,420 per month. - There are 48 weeks of production per year (closed for 4 weeks' holiday - one month); so that the wages and rates are monthly ( 12 months) and the electricity is 11 months. Final Product - A 150ml plastic squeeze bottle of whiteboard cleaner labelled 'WipeOut', boxed and packed in cartons containing 80 bottles per carton. Formulation: - An aqueous solution is prepared by mixing and contains 12%m/m IPA, 3%m/mEGMBE,1% m/m Sulphodex (anionic detergent), 1%m/m Polycoat MM (polymeric skinning agent). Raw materials - Isopropyl Alcohol available in both 25kg and 200kg Drums and the delivered prices are R3.50 per kg and R2.86 per kg respectively - Ethylene Glycol Mono butyl ether (EGMBE) delivered in 25kg drums at R8.26/kg - Sulphodex (solid water-soluble powder) is delivered in 25kg bags at R48.30/kg - Polycoat MM (IPA soluble powder) is delivered in 25kg bags at R142.60/kg Packaging - Glossy colour labels are R1,300 per 4500 - Bottles are R4.25 each regardless of quantity. Process - The production for the current sales is one batch per day of 8500kg which will be filled into the bottles and packed in cartons to produce 100 cartons per day. - As the Polycoat MM is not readily soluble in water, it is mixed separately, initially, with the IPA in the unheated 1,200 litre blend vessel using the standard paddle mixer. Once mixed 30 minutes - the water is added and the solution is heated to 45C which takes some 20 minutes, stirring continuously- - To this heated solution the EGMBE and Sulphodex are added in that order with constant stirring and the temperature maintained for a further hour. - The solution is then allowed to cool without further stirring for a further hour before being gravity fed to the manual filling unit, where the bottles are filled, sealed, labelled and placed in cartons which are sealed and stacked in the store for shipping. Operations - The work is done by two semi-skilled employees working a full day and a 5-day week and 4week month at a total cost of R7,000 per month each. - The heater uses R1,250 per month of electrical energy and the mixer R1,100 per month. - Other overheads, including supervision, rent, rates and water cost, is 28,420 per month. - There are 48 weeks of production per year (closed for 4 weeks' holiday - one month); so that the wages and rates are monthly ( 12 months) and the electricity is 11 monthsStep by Step Solution

There are 3 Steps involved in it

Step: 1

Get Instant Access to Expert-Tailored Solutions

See step-by-step solutions with expert insights and AI powered tools for academic success

Step: 2

Step: 3

Ace Your Homework with AI

Get the answers you need in no time with our AI-driven, step-by-step assistance

Get Started