Answered step by step

Verified Expert Solution

Question

1 Approved Answer

Consider 5-plant, 5-product manufacturing environment where plant capacity is 10,000 unit in one time period (say, a year) and each product demand in that time

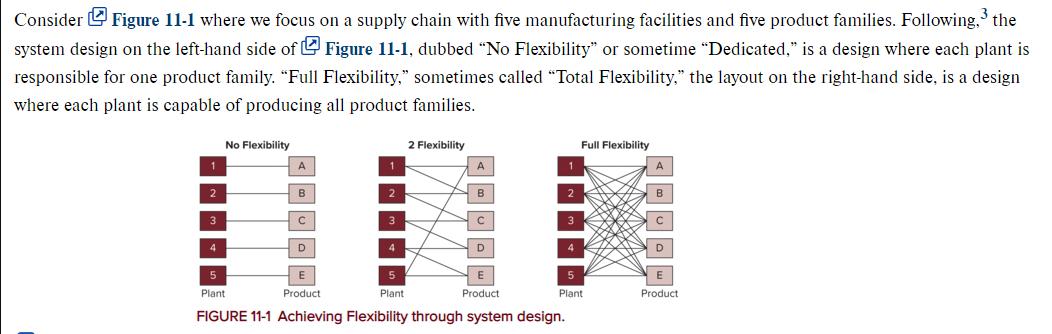

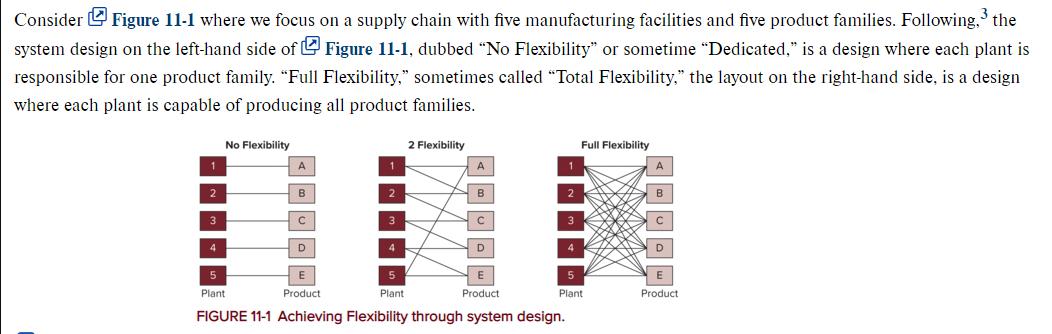

Consider 5-plant, 5-product manufacturing environment where plant capacity is 10,000 unit in one time period (say, a year) and each product demand in that time period is IID Normal with mean 10,000 and a standard deviation of 3,300. Please estimate expected sales for each of the three system designs in Figure 11-1.

Consider Figure 11-1 where we focus on a supply chain with five manufacturing facilities and five product families. Following, the system design on the left-hand side of Figure 11-1, dubbed "No Flexibility" or sometime "Dedicated," is a design where each plant is responsible for one product family. "Full Flexibility," sometimes called "Total Flexibility," the layout on the right-hand side, is a design where each plant is capable of producing all product families. 3 4 No Flexibility A B C D 4 5 Plant 2 Flexibility A B C D 5 E Product Plant FIGURE 11-1 Achieving Flexibility through system design. E Product Full Flexibility 5 Plant A B D E Product

Step by Step Solution

★★★★★

3.49 Rating (149 Votes )

There are 3 Steps involved in it

Step: 1

Get Instant Access to Expert-Tailored Solutions

See step-by-step solutions with expert insights and AI powered tools for academic success

Step: 2

Step: 3

Ace Your Homework with AI

Get the answers you need in no time with our AI-driven, step-by-step assistance

Get Started