Question

Consider the following master production schedule (MPS), product structure diagram, and inventory data: Master Production Schedule: Week 1 2 3 4 5 6 7

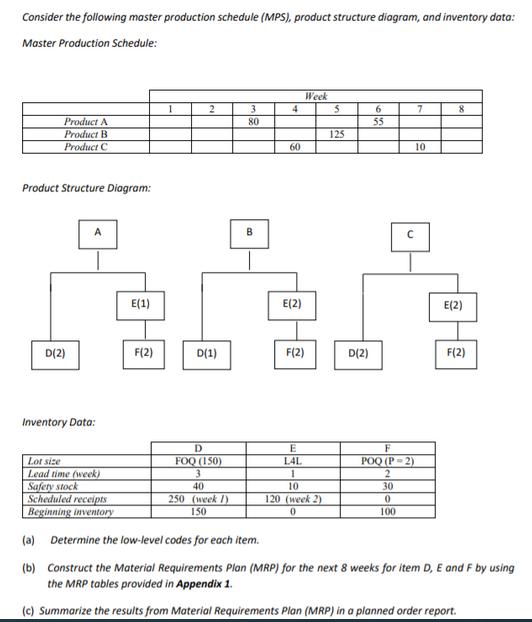

Consider the following master production schedule (MPS), product structure diagram, and inventory data: Master Production Schedule: Week 1 2 3 4 5 6 7 8 Product A 80 55 Product B Product C 125 60 10 Product Structure Diagram: E(1) B C E(2) E(2) no D(2) F(2) D(1) F(2) D(2) F(2) Inventory Data: D Lot size FOQ (150) E LAL F POQ (P-2) Lead time (week) 3 1 2 Safety stock 40 10 30 Scheduled receipts 250 (week 1) 120 (week 2) 0 Beginning inventory 150 0 100 (a) Determine the low-level codes for each item. (b) Construct the Material Requirements Plan (MRP) for the next 8 weeks for item D, E and F by using the MRP tables provided in Appendix 1. (c) Summarize the results from Material Requirements Plan (MRP) in a planned order report.

Step by Step Solution

There are 3 Steps involved in it

Step: 1

Get Instant Access to Expert-Tailored Solutions

See step-by-step solutions with expert insights and AI powered tools for academic success

Step: 2

Step: 3

Ace Your Homework with AI

Get the answers you need in no time with our AI-driven, step-by-step assistance

Get StartedRecommended Textbook for

Essentials Of Computer Organization And Architecture

Authors: Linda Null, Julia Labur

6th Edition

1284259439, 9781284259438

Students also viewed these General Management questions

Question

Answered: 1 week ago

Question

Answered: 1 week ago

Question

Answered: 1 week ago

Question

Answered: 1 week ago

Question

Answered: 1 week ago

Question

Answered: 1 week ago

Question

Answered: 1 week ago

Question

Answered: 1 week ago

Question

Answered: 1 week ago

Question

Answered: 1 week ago

Question

Answered: 1 week ago

Question

Answered: 1 week ago

Question

Answered: 1 week ago

Question

Answered: 1 week ago

Question

Answered: 1 week ago

Question

Answered: 1 week ago

Question

Answered: 1 week ago

Question

Answered: 1 week ago

Question

Answered: 1 week ago

View Answer in SolutionInn App