Question

Crawford Manufacturing is preparing their monthly production plan for one of their major products for the next year and requested assistance in determining possible plans

Crawford Manufacturing is preparing their monthly production plan for one of their major products for the next year and requested assistance in determining possible plans of action. They have traditionally used levelized capacity with overtime, but members of the planning committee would like to compare current production plans with alternative production plans. Two have been suggested. One is simply a minimum cost production plan. Some feel the current amount of overtime is unreasonable due to the level strategy and argue that considerable savings could be realized if overtime was reduced by considering a minimum cost plan. The second alternative reduces inventory to a minimum. Some argue that the flexibility of the current production capacity allows for reducing the cost due to carrying inventory. The president would like to see a comparative analysis before deciding on a final plan. She requested the analysis from us and I said we could provide her with a quality comparative analysis to aid in their decision making during planning.

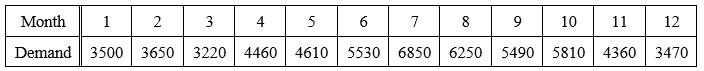

Crawford has provided us with the following information. Labor standard is 50 minutes/unit, regular time labor cost is $48/hour, overtime labor cost is $72/hour, inventory carrying cost is $9.00/item/month, and the FTE standard is 520 hours/quarter. (They operate on 40 hours/week, 52 weeks/year, 12 months/year.) For planning purposes, next year they will begin the year with an inventory of 2000 and they have a targeted ending annual inventory of 1200. Their regular time production capacity is limited to 20 FTEs per month. The overtime is limited to 25% of the regular time production in each month. Since labor hours per week are flexible, there is no hiring or firing costs considered. For this analysis only consider costs due to regular time labor, overtime labor, and inventory carrying. The demand for next year is presented in the table.

Provide a comparative calculation/analysis of their suggested approaches to production plans with detailed information.

9 10 11 12 Month 1 3 4 5 7 Demand 3500 3650 3220 4460 4610 5530 6850 6250 5490 5810 4360 3470

Step by Step Solution

3.32 Rating (152 Votes )

There are 3 Steps involved in it

Step: 1

Solution We will prepare an aggregate plan for both the scenarios and then find which one is better Regular Costhr 3000 Overtime costhr 4500 Subcontractingunit 000 Average Holding costunitperiod 1500 ...

Get Instant Access to Expert-Tailored Solutions

See step-by-step solutions with expert insights and AI powered tools for academic success

Step: 2

Step: 3

Ace Your Homework with AI

Get the answers you need in no time with our AI-driven, step-by-step assistance

Get Started