4. Aggregate capacity management (12 marks) A manufacturing company is setting up a production plan for the product it produces over four seasons. It

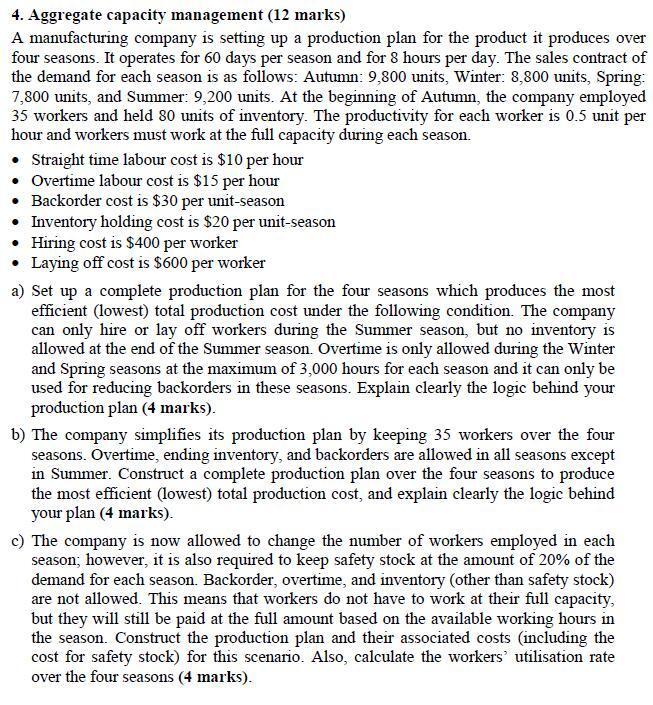

4. Aggregate capacity management (12 marks) A manufacturing company is setting up a production plan for the product it produces over four seasons. It operates for 60 days per season and for 8 hours per day. The sales contract of the demand for each season is as follows: Autumn: 9,800 units, Winter: 8,800 units, Spring: 7,800 units, and Summer: 9,200 units. At the beginning of Autumn, the company employed 35 workers and held 80 units of inventory. The productivity for each worker is 0.5 unit per hour and workers must work at the full capacity during each season. Straight time labour cost is $10 per hour Overtime labour cost is $15 per hour Backorder cost is $30 per unit-season Inventory holding cost is $20 per unit-season Hiring cost is $400 per worker Laying off cost is $600 per worker a) Set up a complete production plan for the four seasons which produces the most efficient (lowest) total production cost under the following condition. The company can only hire or lay off workers during the Summer season, but no inventory is allowed at the end of the Summer season. Overtime is only allowed during the Winter and Spring seasons at the maximum of 3,000 hours for each season and it can only be used for reducing backorders in these seasons. Explain clearly the logic behind your production plan (4 marks). b) The company simplifies its production plan by keeping 35 workers over the four seasons. Overtime, ending inventory, and backorders are allowed in all seasons except in Summer. Construct a complete production plan over the four seasons to produce the most efficient (lowest) total production cost, and explain clearly the logic behind your plan (4 marks). c) The company is now allowed to change the number of workers employed in each season; however, it is also required to keep safety stock at the amount of 20% of the demand for each season. Backorder, overtime, and inventory (other than safety stock) are not allowed. This means that workers do not have to work at their full capacity, but they will still be paid at the full amount based on the available working hours in the season. Construct the production plan and their associated costs (including the cost for safety stock) for this scenario. Also, calculate the workers' utilisation rate over the four seasons (4 marks).

Step by Step Solution

3.54 Rating (158 Votes )

There are 3 Steps involved in it

Step: 1

a Autumn Produce 9800 units 35 workers 80 units of inventory 05 unit per hour productivity Straight time labour cost is 10 per hour Overtime labour cost is 15 per hour Backorder cost is 30 per unitsea...

See step-by-step solutions with expert insights and AI powered tools for academic success

Step: 2

Step: 3

Ace Your Homework with AI

Get the answers you need in no time with our AI-driven, step-by-step assistance

Get Started