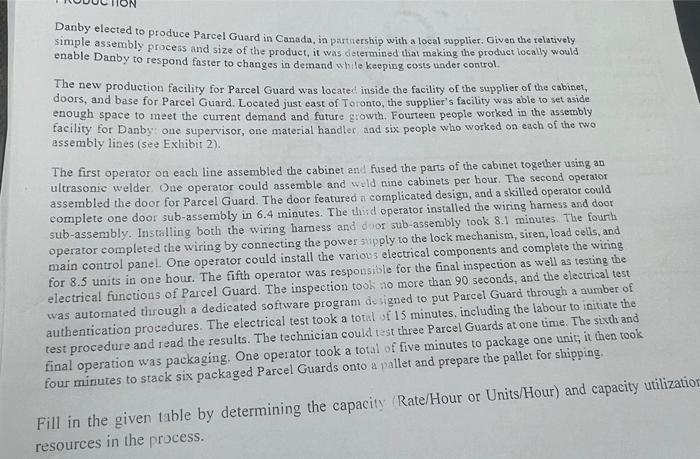

Danby elected to produce Parcel Guard in Canada, in partnership with a local supplier. Given the relatively simple assembly process and size of the product, it was determined that making the product locally would enable Danby to respond faster to changes in demand while keeping costs under control. The new production facility for Parcel Guard was located inside the facility of the supplier of the cabinet, doors, and base for Parcel Guard. Located just east of Toronto, the supplier's facility was able to set aside enough space to meet the current demand and future growth. Fourteen people worked in the assembly facility for Danby one supervisor, one material hander and six people who worked on each of the two assembly lines (see Exhibit 2 ). The first operator on each line assembled the cabinet and fused the parts of the cabinet together using an ultrasonic welder. Dne operator could assemble and weld nine cabinets per bour. The second opetator assembled the door for Parcel Guard. The door featured a complicated design, and a skilled operator could complete one door sub-assembly in 6.4 minutes. The thid operator installed the wiring harness and door sub-assembly. Installing both the wiring harness and dnor sab-assembly took 8.1 minutes. The fourh operator completed the wiring by connecting the power smply to the lock mechanism, siren, load cells, and main control panel. One operator could install the various electrical components and complete the wiring for 8.5 units in one hour. The fifth operator was responstble for the final inspection as well as testing the electrical functions of Parcel Guard. The inspection tool, 10 more than 90 seconds, and the electrical test was automated through a dedicated software program de signed to put Parcel Guard through a aumber of authentication procedures. The electrical test took a totul of 15 minutes, including the labour to initiate the test procedure and read the results. The technician could test three Parcel Guards at one time. The sixth and final operation was packaging. One operator took a total of five minutes to package one unit, it then took four minutes to stack six packaged Parcel Guards onto a pallet and prepare the pallet for shipping. Fill in the given table by determining the capacity Rate/Hour or Units/Hour) and capacity resources in the process. Danby elected to produce Parcel Guard in Canada, in partnership with a local supplier. Given the relatively simple assembly process and size of the product, it was determined that making the product locally would enable Danby to respond faster to changes in demand while keeping costs under control. The new production facility for Parcel Guard was located inside the facility of the supplier of the cabinet, doors, and base for Parcel Guard. Located just east of Toronto, the supplier's facility was able to set aside enough space to meet the current demand and future growth. Fourteen people worked in the assembly facility for Danby one supervisor, one material hander and six people who worked on each of the two assembly lines (see Exhibit 2 ). The first operator on each line assembled the cabinet and fused the parts of the cabinet together using an ultrasonic welder. Dne operator could assemble and weld nine cabinets per bour. The second opetator assembled the door for Parcel Guard. The door featured a complicated design, and a skilled operator could complete one door sub-assembly in 6.4 minutes. The thid operator installed the wiring harness and door sub-assembly. Installing both the wiring harness and dnor sab-assembly took 8.1 minutes. The fourh operator completed the wiring by connecting the power smply to the lock mechanism, siren, load cells, and main control panel. One operator could install the various electrical components and complete the wiring for 8.5 units in one hour. The fifth operator was responstble for the final inspection as well as testing the electrical functions of Parcel Guard. The inspection tool, 10 more than 90 seconds, and the electrical test was automated through a dedicated software program de signed to put Parcel Guard through a aumber of authentication procedures. The electrical test took a totul of 15 minutes, including the labour to initiate the test procedure and read the results. The technician could test three Parcel Guards at one time. The sixth and final operation was packaging. One operator took a total of five minutes to package one unit, it then took four minutes to stack six packaged Parcel Guards onto a pallet and prepare the pallet for shipping. Fill in the given table by determining the capacity Rate/Hour or Units/Hour) and capacity resources in the process