Question

Daniel, Director of Engins Verts, a manufacturer of lawn mowers and leaf blowers/vacuums. He must prepare an overall production plan according to the demand forecasts

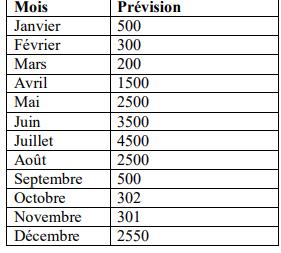

Daniel, Director of Engins Verts, a manufacturer of lawn mowers and leaf blowers/vacuums. He must prepare an overall production plan according to the demand forecasts for engines (see the table below).

Number of employees: 9 employees

Production per day: 9 units per employee

Regular production cost: $50 per unit

Cost of subcontracting: $75 per unit

Hiring cost: $3000 per employee

Thank you cost: $6000 per employee

Storage cost: $1 per unit per month (monthly inventory cost is calculated based on the month's ending inventory). Initial stocks: 300 units

Safety stock: 10% of demand

It is assumed that: employees work every day of the year (ie 365 days a year). Back orders or shortages are not permitted. The monthly inventory cost is calculated based on the ending inventory for the month.

a) Develop a synchronous production strategy that respects the forecast and safety stock of each month, varying only the level of labor by variable duration contracts. Calculate the total cost of your synchronous plan.

b) Compare costs to a level production plan that uses inventory and subcontracting to absorb fluctuations. Calculate the cost of your plan.

Mois Janvier Fvrier Mars Avril Mai Juin Juillet Aot Prvision 500 300 200 1500 2500 3500 4500 2500 500 302 Novembre 301 Dcembre 2550 Septembre Octobre

Step by Step Solution

There are 3 Steps involved in it

Step: 1

Synchronous Production Strategy In a synchronous production strategy the goal is to match production with demand each month while considering the safe...

Get Instant Access to Expert-Tailored Solutions

See step-by-step solutions with expert insights and AI powered tools for academic success

Step: 2

Step: 3

Ace Your Homework with AI

Get the answers you need in no time with our AI-driven, step-by-step assistance

Get Started