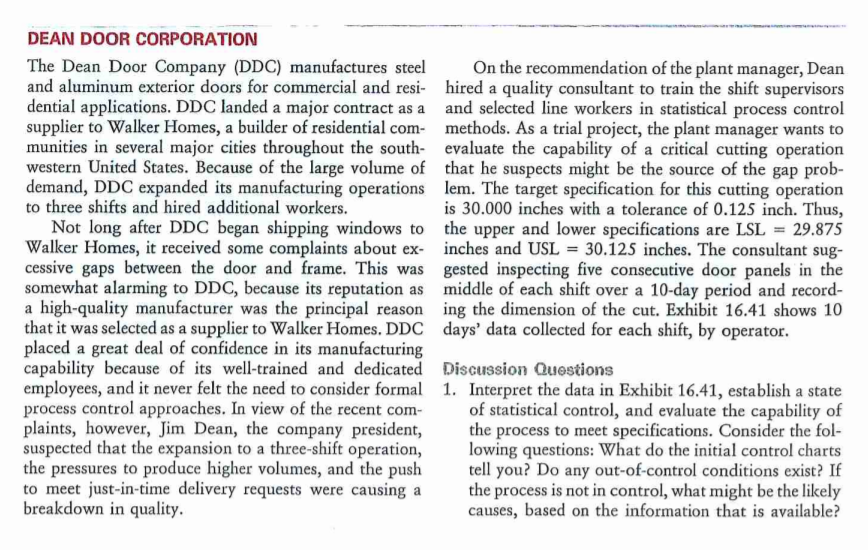

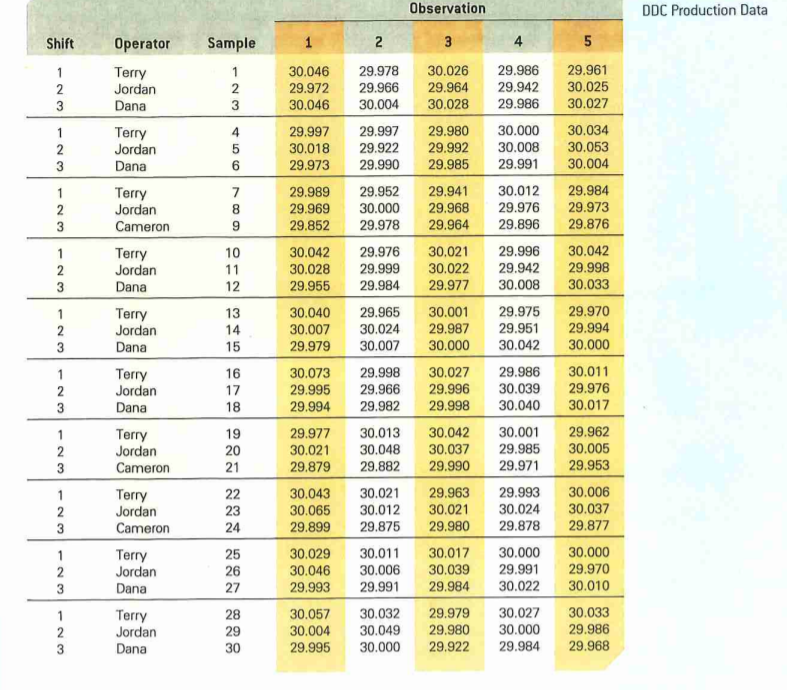

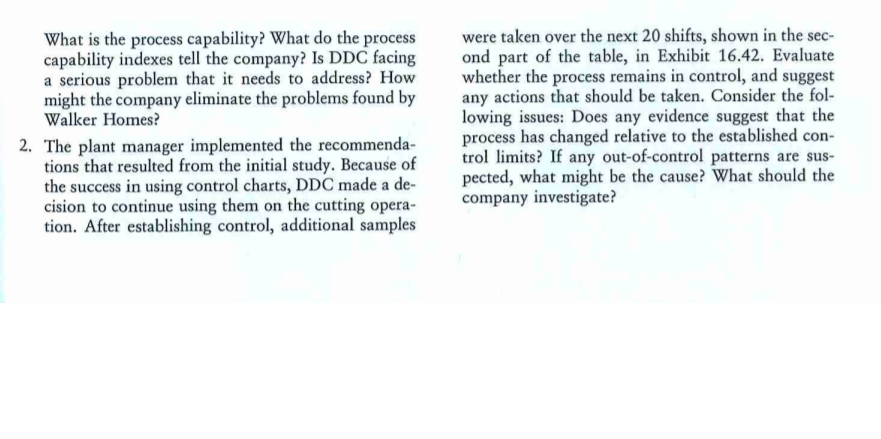

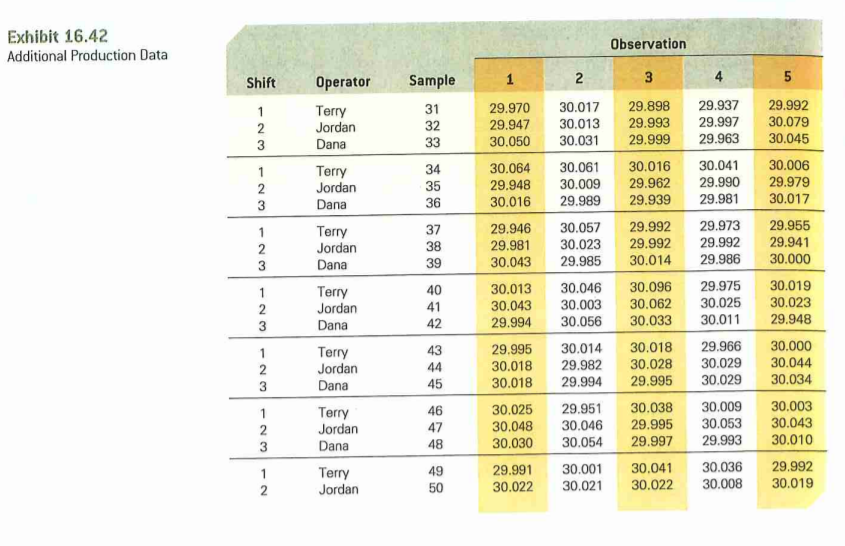

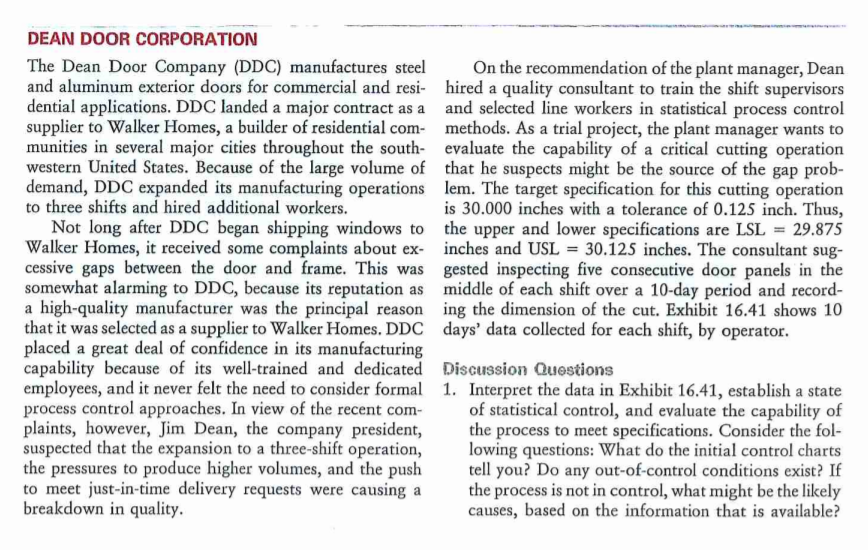

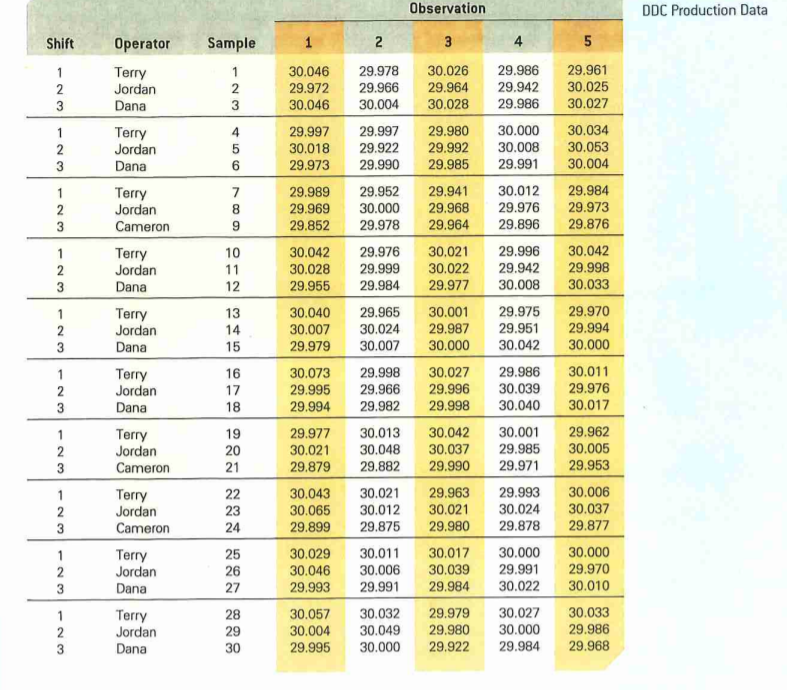

DEAN DOOR CORPORATION The Dean Door Company (DDC) manufactures steel On the recommendation of the plant manager, Dean and aluminum exterior doors for commercial and resi- hired a quality consultant to train the shift supervisors dential applications. DDC landed a major contract as a and selected line workers in statistical process control supplier to Walker Homes, a builder of residential com- methods. As a trial project, the plant manager wants to munities in several major cities throughout the south- evaluate the capability of a critical cutting operation western United States. Because of the large volume of that he suspects might be the source of the gap prob- demand, DDC expanded its manufacturing operations lem. The target specification for this cutting operation to three shifts and hired additional workers. is 30.000 inches with a tolerance of 0.125 inch. Thus, Not long after DDC began shipping windows to the upper and lower specifications are LSL = 29.875 Walker Homes, it received some complaints about ex- inches and USL = 30.125 inches. The consultant sug- cessive gaps between the door and frame. This was gested inspecting five consecutive door panels in the somewhat alarming to DDC, because its reputation as middle of each shift over a 10-day period and record- a high-quality manufacturer was the principal reason ing the dimension of the cut. Exhibit 16.41 shows 10 that it was selected as a supplier to Walker Homes. DDC days' data collected for each shift, by operator. placed a great deal of confidence in its manufacturing capability because of its well-trained and dedicated Discussion Questions employees, and it never felt the need to consider formal 1. Interpret the data in Exhibit 16.41, establish a state process control approaches. In view of the recent com of statistical control, and evaluate the capability of plaints, however, Jim Dean, the company president, the process to meet specifications. Consider the fol- suspected that the expansion to a three-shift operation, lowing questions: What do the initial control charts the pressures to produce higher volumes, and the push tell you? Do any out-of-control conditions exist? If to meet just-in-time delivery requests were causing a the process is not in control, what might be the likely breakdown in quality. causes, based on the information that is available? Observation DDC Production Data Shift Operator Sample Terry Jordan Dana 30.046 29.972 30.046 29.978 29.966 30.004 30.026 29.964 30.028 29.986 29.942 29.986 29.961 30.025 30.027 Terry Jordan Dana 29.997 30.018 29.973 29.997 29.922 29.990 29.980 29.992 29.985 30.000 30.008 29.991 30.034 30.053 30.004 Terry Jordan Cameron 29.989 29.969 29.852 29.952 30.000 29.978 29.941 29.968 29.964 30.012 29.976 29.896 29.984 29.973 29.876 Terry Jordan 30.042 30.028 29.955 29.976 29.999 29.984 30.021 30.022 29.977 29.996 29.942 30.008 30.042 29.998 30.033 Dana ******************************** Terry Jordan Dana 30.040 30.007 29.979 29.965 30.024 30.007 30.001 29.987 30.000 29.975 29.951 30.042 29.970 29.994 30.000 Terry Jordan Dana 30.073 29.995 29.994 29.998 29.966 29.982 30.027 29.996 29.998 29.986 30.039 30.040 30.011 29.976 30.017 Terry Jordan Cameron 29.977 30.021 29.879 30.013 30.048 29.882 30.042 30.037 29.990 30.001 29.985 29.971 29.962 30.005 29.953 Terry Jordan Cameron 30.043 30.065 29.899 30.021 30.012 29.875 29.963 30.021 29.980 29.993 30.024 29.878 30.006 30.037 29.877 Terry Jordan Dana 30.029 30.046 29.993 30.011 30.006 29.991 30.017 30.039 29.984 30.000 29.991 30.022 30.000 29.970 30.010 Terry Jordan Dana 30.057 30.004 29.995 30.032 30.049 30.000 29.979 29.980 29.922 30.027 30.000 29.984 30.033 29.986 29.968 What is the process capability? What do the process capability indexes tell the company? Is DDC facing a serious problem that it needs to address? How might the company eliminate the problems found by Walker Homes? 2. The plant manager implemented the recommenda- tions that resulted from the initial study. Because of the success in using control charts, DDC made a de- cision to continue using them on the cutting opera- tion. After establishing control, additional samples were taken over the next 20 shifts, shown in the sec- ond part of the table, in Exhibit 16.42. Evaluate whether the process remains in control, and suggest any actions that should be taken. Consider the fol- lowing issues: Does any evidence suggest that the process has changed relative to the established con- trol limits? If any out-of-control patterns are sus- pected, what might be the cause? What should the company investigate? Exhibit 16.42 Additional Production Data Observation Shift Operator Sample Terry Jordan Dana 29.970 29.947 30.050 30.017 30.013 30.031 29.898 29.993 29.999 29.937 29.997 29.963 29.992 30.079 30.045 Terry Jordan 30.064 29.948 30.016 30.061 30.009 29.989 30.016 29.962 29.939 30.041 29.990 29.981 30.006 29.979 30.017 Dana Terry Jordan Dana 29.946 29.981 30.043 30.057 30.023 29.985 29.992 29.992 30.014 29.973 29.992 29.986 29.955 29.941 30.000 Terry Jordan Dana 30.013 30.043 29.994 30.046 30.003 30.056 30.096 30.062 30.033 29.975 30.025 30.011 30.019 30.023 29.948 Terry Jordan Dana 29.995 30.018 30.018 30.014 29.982 29.994 30.018 30.028 29.995 29.966 30.029 30.029 30.000 30.044 30.034 Terry Jordan 30.025 30.048 30.030 29.951 30.046 30.054 30.038 29.995 29.997 30.009 30.053 29.993 30.003 30.043 30.010 Dana Terry Jordan 29.991 30.022 30.001 30.021 30.041 30.022 30.036 30.008 29.992 30.019 DEAN DOOR CORPORATION The Dean Door Company (DDC) manufactures steel On the recommendation of the plant manager, Dean and aluminum exterior doors for commercial and resi- hired a quality consultant to train the shift supervisors dential applications. DDC landed a major contract as a and selected line workers in statistical process control supplier to Walker Homes, a builder of residential com- methods. As a trial project, the plant manager wants to munities in several major cities throughout the south- evaluate the capability of a critical cutting operation western United States. Because of the large volume of that he suspects might be the source of the gap prob- demand, DDC expanded its manufacturing operations lem. The target specification for this cutting operation to three shifts and hired additional workers. is 30.000 inches with a tolerance of 0.125 inch. Thus, Not long after DDC began shipping windows to the upper and lower specifications are LSL = 29.875 Walker Homes, it received some complaints about ex- inches and USL = 30.125 inches. The consultant sug- cessive gaps between the door and frame. This was gested inspecting five consecutive door panels in the somewhat alarming to DDC, because its reputation as middle of each shift over a 10-day period and record- a high-quality manufacturer was the principal reason ing the dimension of the cut. Exhibit 16.41 shows 10 that it was selected as a supplier to Walker Homes. DDC days' data collected for each shift, by operator. placed a great deal of confidence in its manufacturing capability because of its well-trained and dedicated Discussion Questions employees, and it never felt the need to consider formal 1. Interpret the data in Exhibit 16.41, establish a state process control approaches. In view of the recent com of statistical control, and evaluate the capability of plaints, however, Jim Dean, the company president, the process to meet specifications. Consider the fol- suspected that the expansion to a three-shift operation, lowing questions: What do the initial control charts the pressures to produce higher volumes, and the push tell you? Do any out-of-control conditions exist? If to meet just-in-time delivery requests were causing a the process is not in control, what might be the likely breakdown in quality. causes, based on the information that is available? Observation DDC Production Data Shift Operator Sample Terry Jordan Dana 30.046 29.972 30.046 29.978 29.966 30.004 30.026 29.964 30.028 29.986 29.942 29.986 29.961 30.025 30.027 Terry Jordan Dana 29.997 30.018 29.973 29.997 29.922 29.990 29.980 29.992 29.985 30.000 30.008 29.991 30.034 30.053 30.004 Terry Jordan Cameron 29.989 29.969 29.852 29.952 30.000 29.978 29.941 29.968 29.964 30.012 29.976 29.896 29.984 29.973 29.876 Terry Jordan 30.042 30.028 29.955 29.976 29.999 29.984 30.021 30.022 29.977 29.996 29.942 30.008 30.042 29.998 30.033 Dana ******************************** Terry Jordan Dana 30.040 30.007 29.979 29.965 30.024 30.007 30.001 29.987 30.000 29.975 29.951 30.042 29.970 29.994 30.000 Terry Jordan Dana 30.073 29.995 29.994 29.998 29.966 29.982 30.027 29.996 29.998 29.986 30.039 30.040 30.011 29.976 30.017 Terry Jordan Cameron 29.977 30.021 29.879 30.013 30.048 29.882 30.042 30.037 29.990 30.001 29.985 29.971 29.962 30.005 29.953 Terry Jordan Cameron 30.043 30.065 29.899 30.021 30.012 29.875 29.963 30.021 29.980 29.993 30.024 29.878 30.006 30.037 29.877 Terry Jordan Dana 30.029 30.046 29.993 30.011 30.006 29.991 30.017 30.039 29.984 30.000 29.991 30.022 30.000 29.970 30.010 Terry Jordan Dana 30.057 30.004 29.995 30.032 30.049 30.000 29.979 29.980 29.922 30.027 30.000 29.984 30.033 29.986 29.968 What is the process capability? What do the process capability indexes tell the company? Is DDC facing a serious problem that it needs to address? How might the company eliminate the problems found by Walker Homes? 2. The plant manager implemented the recommenda- tions that resulted from the initial study. Because of the success in using control charts, DDC made a de- cision to continue using them on the cutting opera- tion. After establishing control, additional samples were taken over the next 20 shifts, shown in the sec- ond part of the table, in Exhibit 16.42. Evaluate whether the process remains in control, and suggest any actions that should be taken. Consider the fol- lowing issues: Does any evidence suggest that the process has changed relative to the established con- trol limits? If any out-of-control patterns are sus- pected, what might be the cause? What should the company investigate? Exhibit 16.42 Additional Production Data Observation Shift Operator Sample Terry Jordan Dana 29.970 29.947 30.050 30.017 30.013 30.031 29.898 29.993 29.999 29.937 29.997 29.963 29.992 30.079 30.045 Terry Jordan 30.064 29.948 30.016 30.061 30.009 29.989 30.016 29.962 29.939 30.041 29.990 29.981 30.006 29.979 30.017 Dana Terry Jordan Dana 29.946 29.981 30.043 30.057 30.023 29.985 29.992 29.992 30.014 29.973 29.992 29.986 29.955 29.941 30.000 Terry Jordan Dana 30.013 30.043 29.994 30.046 30.003 30.056 30.096 30.062 30.033 29.975 30.025 30.011 30.019 30.023 29.948 Terry Jordan Dana 29.995 30.018 30.018 30.014 29.982 29.994 30.018 30.028 29.995 29.966 30.029 30.029 30.000 30.044 30.034 Terry Jordan 30.025 30.048 30.030 29.951 30.046 30.054 30.038 29.995 29.997 30.009 30.053 29.993 30.003 30.043 30.010 Dana Terry Jordan 29.991 30.022 30.001 30.021 30.041 30.022 30.036 30.008 29.992 30.019