Question

-Determine the class of induction motor and its maximum horsepower to be specified. - Design and calculate shafts with a suitable diameter (shape design). -Determine

-Determine the class of induction motor and its maximum horsepower to be specified.

- Design and calculate shafts with a suitable diameter (shape design).

-Determine the number and location of supporting bearings.

- Calculate and select appropriate bearings for 5 years of life and 12 hours of work per day.

- Design and select a V- belt system to drive the drive shaft

- Design a gear chain (with 4 gears) for speed reduction instead of V-belts, and determine and calculate the gears. (a sketch for recommendation shown in Fig. 2)

- Design an appropriate brake system that is placed on BH

- Select and design appropriate couplings and joints.

- Use Tolerances as it is needed.

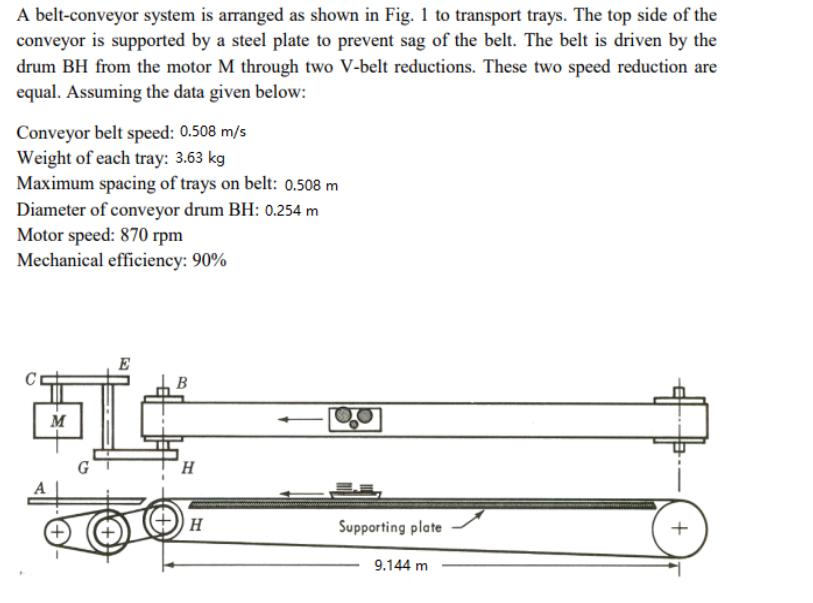

A belt-conveyor system is arranged as shown in Fig. 1 to transport trays. The top side of the conveyor is supported by a steel plate to prevent sag of the belt. The belt is driven by the drum BH from the motor M through two V-belt reductions. These two speed reduction are equal. Assuming the data given below: Conveyor belt speed: 0.508 m/s Weight of each tray: 3.63 kg Maximum spacing of trays on belt: 0.508 m Diameter of conveyor drum BH: 0.254 m Motor speed: 870 rpm Mechanical efficiency: 90% E alt M G B H H Supporting plate 9.144 m

Step by Step Solution

3.41 Rating (154 Votes )

There are 3 Steps involved in it

Step: 1

Get Instant Access to Expert-Tailored Solutions

See step-by-step solutions with expert insights and AI powered tools for academic success

Step: 2

Step: 3

Ace Your Homework with AI

Get the answers you need in no time with our AI-driven, step-by-step assistance

Get Started