Answered step by step

Verified Expert Solution

Question

1 Approved Answer

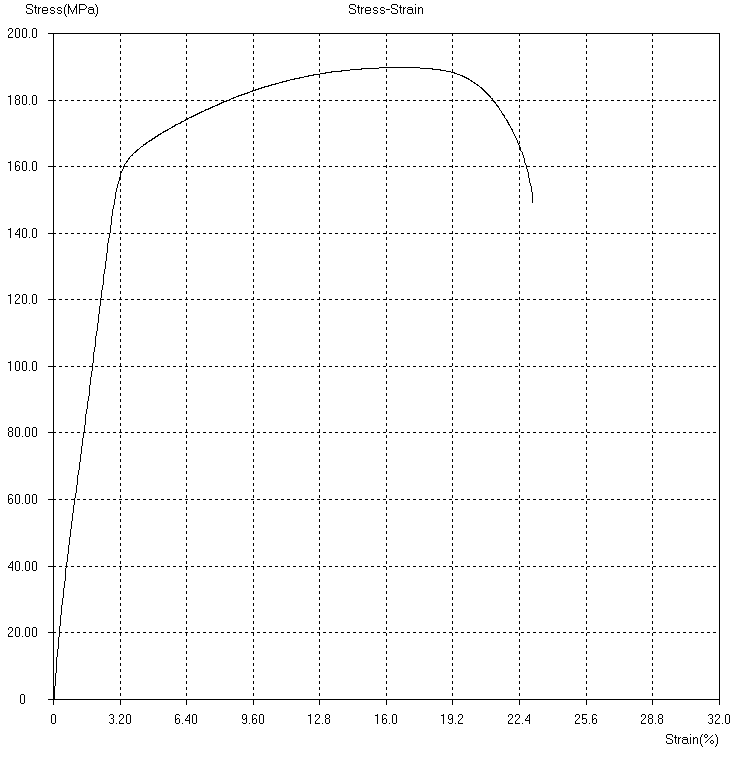

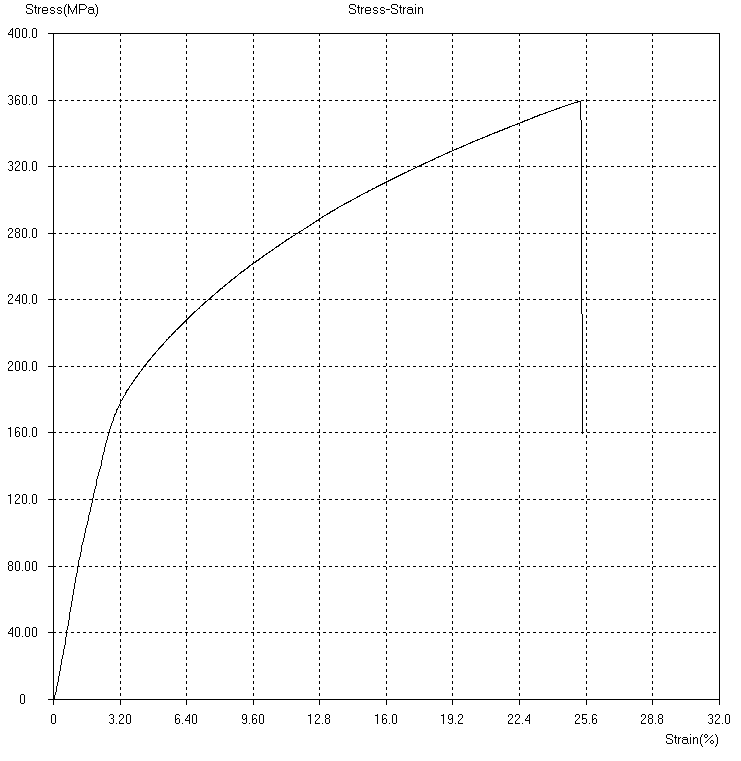

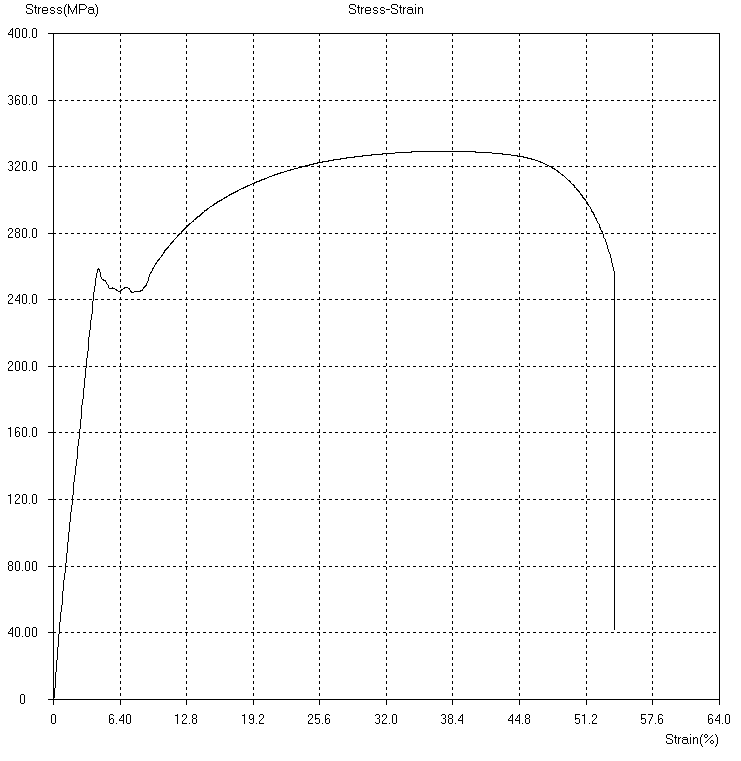

Determine the percentage elongation after fracture using theinitial and final lengths of the provided specimens. Calculate the initial area and the final area of each

|

|

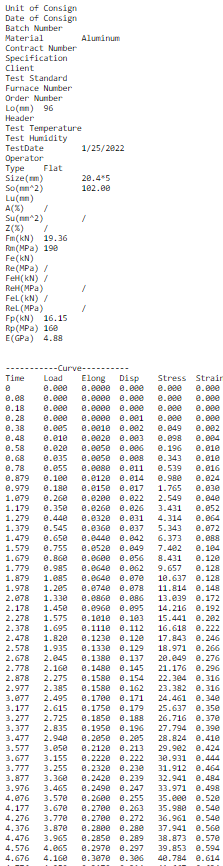

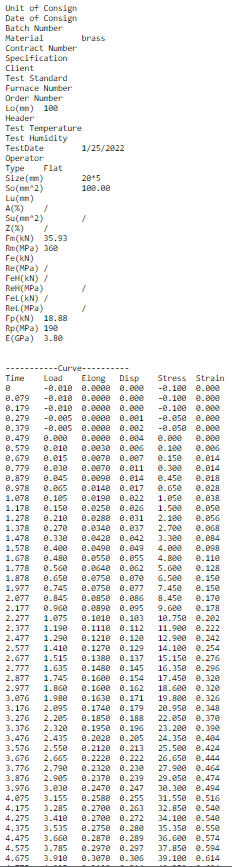

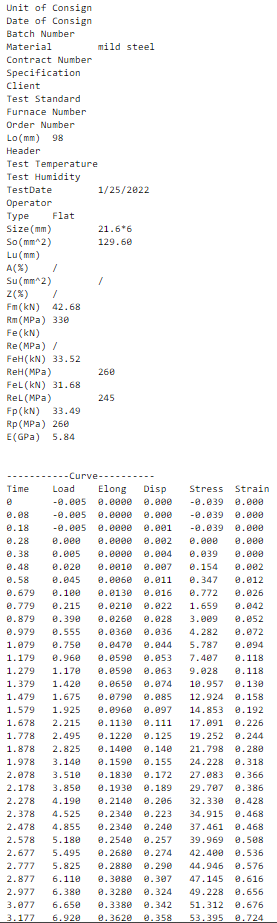

Stress (MPa) 200.0 180.0 160.0 140.0 120.0 100.0 80.00 60.00 40.00 20.00 0 0 3.20 6.40 9.60 12.8 Stress-Strain 16.0 19.2 22.4 25.6 28.8 32.0 Strain(%) Stress (MPa) 400.0 360.0 320.0 280.0 240.0 200.0 160.0 120.0 80.00 40.00 0 0 3.20 6.40 9.60 12.8 Stress-Strain 16.0 19.2 22.4 25.6 28.8 32.0 Strain(%) Stress (MPa) 400.0 360.0 320.0 280.0 240.0 200.0 160.0 120.0 80.00 40.00 0 0 6.40 12.8 19.2 25.6 Stress-Strain 32.0 38.4 44.8 51.2 57.6 64.0 Strain(%) Unit of Consign Date of Consign Batch Number Material Contract Number Specification Client Test Standard Furnace Number Order Number Lo(mm) 96 Header Test Temperature Test Humidity TestDate Operator Type Size(mm) So(mm^2) Lu(nn) / A(%) Su(mn^2) Z(%) Fm(kN) 19.36 Rm (MPa) 198 Fe(kN) Re(MPa) / FeH(kN) / ReH(MPa) Fel(kN) / Flat / ReL (MPa) Fp(kN) 16.15 Rp(MPa) 160 E(GPa) 4.88 0.08 0.18 Aluminum Time Load 1/25/2022 20.4*5 102.00 -Curve- 1 Elong Disp 0.000 0.0000 0.000 0.000 0.000 2.378 1.695 2.478 1.820 Stress 0.000 0.0000 0.000 0.000 0.0000 0.000 0.000 0.28 0.000 0.38 0.005 0.48 0.010 0.58 0.020 0.68 0.035 0.78 0.055 0.879 0.100 0.979 0.180 1.879 0.260 1.179 0.350 1.279 0.440 1.379 0.545 1.479 0.650 0.0448 0.042 1.579 0.755 0.0520 0.049 0.0600 0.056 0.120 0.985 0.0640 0.062 9.657 0.128 1.885 0.0640 0.070 10.637 0.128 11.814 0.148 13.039 0.172 14.216 0.192 15.441 0.202 16.618 0.222 17.843 0.246 18.971 0.266 20.849 0.276 21.176 0.296 22.304 0.316 23.382 0.316 0.0000 0.001 0.000 0.0010 0.002 0.049 0.098 0.0028 0.003 0.0050 0.006 0.196 0.0050 0.008 0.343 0.0080 0.011 0.539 0.0128 0.014 0.0150 0.017 0.0200 0.022 0.0268 0.026 0.0320 0.031 0.0368 0.037 1.679 0.860 1.779 1.879 1.978 1.205 0.0748 0.878 2.078 1.330 0.8868 0.886 2.178 1.450 0.0960 0.095 2.278 1.575 Strain 0.000 0.000 0.000 0.000 0.002 0.004 0.010 0.010 0.016 0.024 1.765 0.030 2.549 0.840 3.431 0.052 4.314 0.064 5.343 0.072 6.373 0.088 7.482 e. 184 8.431 0.1010 0.103 0.1110 0.112 0.1238 0.128 2.578 1.935 0.1330 0.129 2.678 2.045 0.1388 0.137 2.778 2.160 0.1480 0.145 0.1580 0.154 2.878 2.275 0.1580 0.162 2.977 2.385 3.877 2.495 0.1700 0.171 2.615 3.177 3.277 2.725 3.377 2.835 0.1950 0.196 3.477 2.940 0.2858 0.285 3.577 3.050 0.2120 0.213 0.2220 0.222 3.677 3.155 3.777 3.255 0.2320 0.230 3.877 3.360 0.2420 0.239 3.976 3.465 0.2490 0.247 4.876 3.570 0.2600 0.255 4.177 3.670 0.2700 0.263 4.276 3.770 0.2700 0.272 4.376 3.870 0.2800 8.288 4.476 3.965 0.2850 0.289 4.576 4.065 0.2970 0.297 4.676 4.160 0.3070 0.386 0.1750 0.179 0.1850 0.188 24.461 0.340 25.637 0.358 26.716 0.370 27.794 0.390 28.824 0.418 29.902 0.424 30.931 0.444 31.912 0.464 32.941 0.484 33.971 0.498 35.000 0.528 35.988 0.540 36.961 0.540 37.941 0.560 38.873 0.570 39.853 0.594 48.784 0.614 Unit of Consign Date of Consign Batch Number Material Contract Number Specification Client Test Standard Furnace Number Order Number Lo(mm) 100 Header Test Temperature Test Humidity TestDate Operator Type Size(mm) So(mn^2) Lu(nn) A(%) Su(mn^2) Flat Z(%) / Fm(KN) 35.93 Rm(MPa) 360 / Fe(kN) Re(MPa) / FeH(kN) / ReH(MPa) Fel (kN) / ReL (MPa) Time 0 Fp(kN) 18.88 Rp(MPa) 198 E(GPa) 3.80 1.278 1.378 brass 1/25/2022 20*5 100.00 1 -Curve- Load -0.010 0.0000 0.000 Elong Disp Stress Strain -0.180 0.000 0.079 -0.010 0.0000 0.000 0.179 -0.010 0.0000 0.000 0.279 -0.005 0.0000 0.001 0.379 -0.005 0.0000 0.002 0.479 0.000 0.0000 0.084 0.579 0.010 0.0030 0.006 0.679 0.015 0.0070 0.007 0.779 0.030 0.0070 0.011 0.879 0.045 0.0090 0.014 0.978 0.065 0.0148 0.017 1.878 0.105 0.0190 0.022 1.050 1.178 0.150 0.0250 0.026 1.500 0.210 0.0280 0.031 2.100 8.270 0.0348 0.037 2.700 1.478 0.330 0.0420 0.042 3.300 1.578 0.400 0.0490 0.049 4.980 1.678 0.480 0.0550 0.055 4.800 1.778 0.560 0.0640 0.062 5.600 1.878 0.650 6.500 1.977 7.450 2.877 0.845 8.450 0.0750 0.070 0.745 0.8750 0.877 0.0850 0.086 -0.180 0.000 -0.100 0.000 -0.050 -0.050 0.1950 0.196 0.2820 8.285 0.2120 0.213 0.000 0.100 0.150 0.300 0.450 0.650 0.000 0.000 0.000 0.086 0.014 0.014 0.018 0.128 0.150 0.150 0.170 0.0890 0.095 9.600 0.178 0.1010 0.103 10.750 0.202 0.1110 0.112 11.900 0.222 12.900 0.242 0.028 0.038 0.050 0.056 0.068 0.084 0.098 0.110 2.177 0.960 2.277 1.875 2.377 1.190 2.477 1.290 0.1210 0.128 2.577 1.410 0.1270 0.129 2.677 1.515 0.1380 0.137 2.777 1.635 0.1480 0.145 2.877 1.745 0.1600 0.154 2.977 1.860 0.1600 0.162 0.1638 0.171 3.876 1.980 3.176 2.095 0.1740 0.179 3.276 2.285 0.1850 0.188 3.376 2.320 3.476 2.435 2.550 3.576 0.2220 8.222 3.676 2.665 3.776 2.790 0.2320 0.230 3.876 2.905 0.2370 0.239 3.976 3.030 0.2470 0.247 30.300 0.494 4.075 3.155 0.2580 0.255 31.550 0.516 4.175 3.285 0.2700 0.263 4.275 3.410 0.2708 0.272 4.375 3.535 0.2750 0.280 4.475 3.660 0.2870 0.289 4.575 3.785 0.2970 0.297 4.675 3.910 0.3070 0.386 14.100 0.254 15.150 0.276 16.350 0.296 17.450 0.320 18.600 0.320 19.880 0.326 20.950 0.348 22.050 0.370 23.200 0.390 24.350 0.484 25.500 0.424 26.650 0.444 27.900 0.464 29.050 0.474 32.850 0.540 34.100 0.540 35.350 0.550 36.600 0.574 37.850 0.594 39.100 0.614 Unit of Consign Date of Consign Batch Number Material Contract Number Specification Client Test Standard Furnace Number Order Number Lo (mm) 98 Header Test Temperature Test Humidity TestDate Operator Type Size (mm) Flat So (mm^2) Lu (mm) A(%) Su(mm^2) Z(%) / Fm(kN) 42.68 / Rm (MPa) 330 Fe (kN) Re (MPa) / FeH(kN) 33.52 ReH(MPa) FeL(kN) 31.68 Time ReL (MPa) Fp (kN) 33.49 Rp (MPa) 260 E(GPa) 5.84 mild steel 1/25/2022 21.6*6 129.60 260 245 -Curve- Load -0.005 0.0000 0.000 0.08 -0.005 0.0000 0.000 -0.005 0.0000 0.001 2.578 5.180 Elong Disp Stress Strain -0.039 0.000 -0.039 0.000 -0.039 0.18 0.28 0.000 0.38 0.005 0.0000 0.004 0.48 0.020 0.0010 0.007 0.154 0.045 0.0060 0.011 0.347 0.58 0.679 0.100 0.0130 0.016 0.772 0.779 0.215 0.0210 0.822 1.659 0.879 0.390 0.0260 0.028 0.979 0.555 0.0360 0.036 1.079 0.750 0.0470 0.044 0.0590 0.053 0.0000 0.002 0.000 0.039 1.179 0.960 1.279 1.170 0.0590 0.063 1.379 1.420 0.0650 0.074 1.479 1.675 0.0790 0.085 1.579 1.925 1.678 2.215 0.0960 0.897 0.1130 0.111 1.778 2.495 0.1220 0.125 1.878 2.825 0.1400 0.140 1.978 3.140 0.1590 0.155 2.078 3.510 0.1830 0.172 2.178 3.850 0.1930 0.189 2.278 4.190 0.2140 0.206 2.378 4.525 0.2340 0.223 2.478 4.855 0.2340 0.240 0.2540 0.257 2.677 5.495 0.2680 0.274 2.777 5.825 0.2880 0.290 2.877 6.110 0.3080 0.307 2.977 6.380 0.3280 0.324 3.877 6.650 0.3380 0.342 3.177 6.928 0.3620 0.358 0.000 0.000 0.000 0.002 0.012 0.026 0.042 0.052 0.072 0.094 3.009 4.282 5.787 7.407 0.118 9.028 0.118 10.957 0.130 12.924 0.158 14.853 0.192 17.091 0.226 19.252 0.244 21.798 0.280 24.228 0.318 27.083 0.366 29.707 0.386 32.330 0.428 34.915 0.468 37.461 0.468 39.969 0.508 42.400 0.536 44.946 0.576 47.145 0.616 49.228 0.656 51.312 0.676 53.395 0.724

Step by Step Solution

★★★★★

3.55 Rating (148 Votes )

There are 3 Steps involved in it

Step: 1

Get Instant Access to Expert-Tailored Solutions

See step-by-step solutions with expert insights and AI powered tools for academic success

Step: 2

Step: 3

Ace Your Homework with AI

Get the answers you need in no time with our AI-driven, step-by-step assistance

Get Started