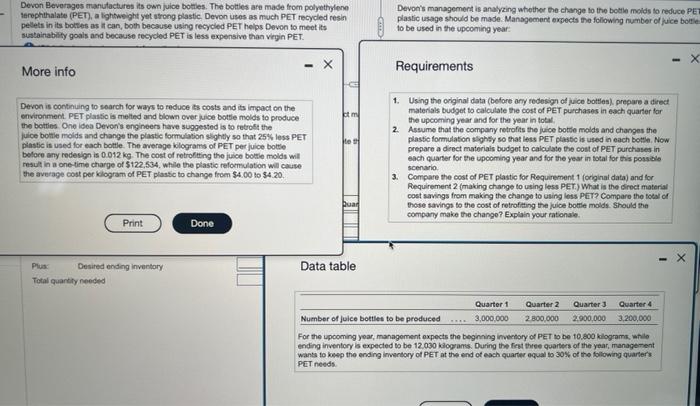

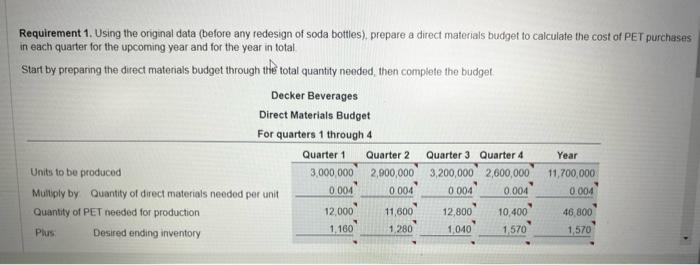

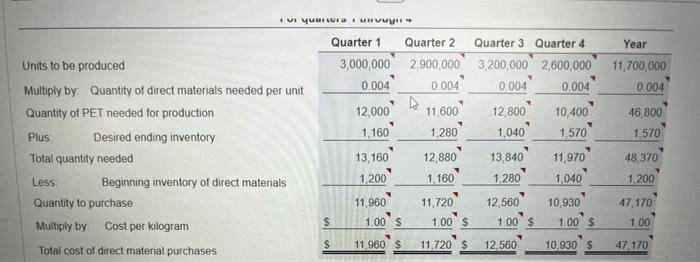

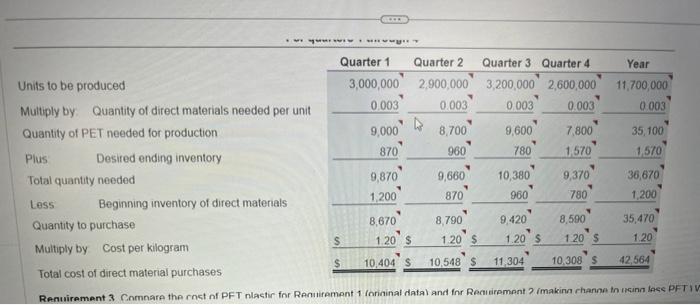

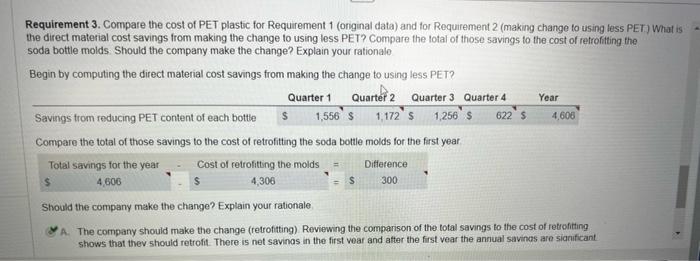

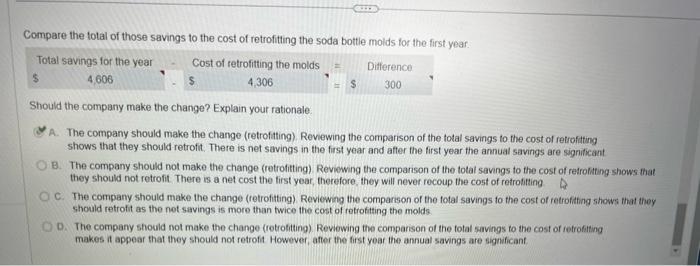

Devon Beverages manutactures its own juice boties. The bottles are made from polyettylene terephithalate (PET), a lightweight yet atrong plastic. Devon uses as much PET recycled resin pelets in its bottes as if can, both because using recycled PET helps Dovon to meet its Devor's managemert is analyzing whether the change to the botile moids to reduce PE: suatainability goals and because recycled PET is less expensive than vegin PET. plastic usage should be made. Mansgement expects the following number of juce botie to be used in the upcoming year: Requirements 1. Using the original data (before any redesign of juice bottles) prepane a direct Devon is continuing to search for ways to reduce ts costs and its impact on the environment. PETT plassio is melted and blown over juce botbe molds to produce the betties One idea Devon's engineers have suggested is to setroft the juice botile moids and change the plastic formulation sightly so that 25% less PET piastic is used for each bottle. The average klograms of PET per juice botte betore any redesign is 0.012kg. The cost of retrofting the juice bottie molds with result in a one-time charge of 5122,534 , whlle the piastio reformulation will caure the average cost per kilogram of PET plastic to change feom $4.00 lo $4.20. the upooming year and for the year in totat. 2. Assume that the company retrofits the juice botte molds and changes the plastio formulation sifghsy so that less PET plasse is used in each bottie. Now. prepare a direct muterials budget to calculato the cost of PET purchases in each quaner for the upcoming year and for the year in total for this possale scenaria. 3. Compare the cost of PET plastic for Requirement 1 (original data) and for fiequirement 2 (making change to using less PEr.) What is the direct material cost savings from making the chango to using less Pari? Compare the toekl of : hose savings to the cost of retrofiting the juice bottie molds. Should the compary make the change? Explain your rationale. Requirement 1. Using the original data (before any redesign of soda bottles), prepare a direct matenals budget to calculate the cost of PET purchases in each quarter for the upcoming year and for the year in total Start by preparing the direct materials budget through thes total quantify needed, then complete the budget * HAnnun, expribnh in, Units to be produced Multiply by Quantity of direct materials needed per unit Quantity of PET needed for production Plus Desired ending inventory Total quantity needed Less Beginning inventory of direct materials Quantity to purchase Multiply by Cost per kilogram Total cost of direct material purchases Requirement 3. Compare the cost of PET plastic for Requirement 1 (original data) and for Requirement 2 (making change to using less PET) What is the direct material cost savings from making the change to using less PET? Compare the total of those savings to the cost of retrofitting the soda bottle molds. Should the company make the change? Explain your rationalo Begin by computing the direct material cost savings from making the change to using less PET? Compare the total of those savings to the cost of retrofitting the soda bottle molds for the frist year. Should the company make the change? Explain your rationale. A. The company should make the change (retrofiting) Reviewing the comparison of the total savings to the cost of retrofiting shows that thev should retrofit. There is net savinas in the first wear and atter the first vear the annual savinas are sianificant. Compare the fotal of those savings to the cost of retrofitting the soda bottle molds for the first year. Should the company make the change? Explain your rationale. A. The company should make the change (retroftting). Revewing the comparison of the total savings to the cost of retrofiting shows that they should retroft. There is net savings in the first year and after the first year the annual savings are significant B. The company should not make the change (retroftting). Reviewing the comparison of the total savings to the cost of retrofiting shows that they should not retrofit. There is a net cost the first year, therefore, they will never recoup the cost of retrofiting c. The company should make the change (retrofiting). Reviewing the comparison of the total savings fo the cost of retrofiting shows that they should retrofit as the not savings is more than twice the cost of retrofiting the molds. D. The company should not make the change (rotrotiting). Reviewing the comparison of the total sivings to the cost of retrofiting makes it appear that they should not retroft However, after the first year the annual savings are significant