Question

Direct labor or machine hours may not be the appropriate cost driver for overhead in all areas of manufacturing due to the complexities of many

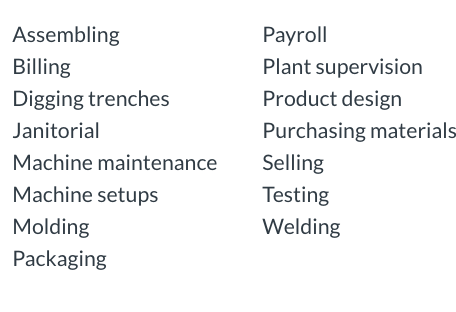

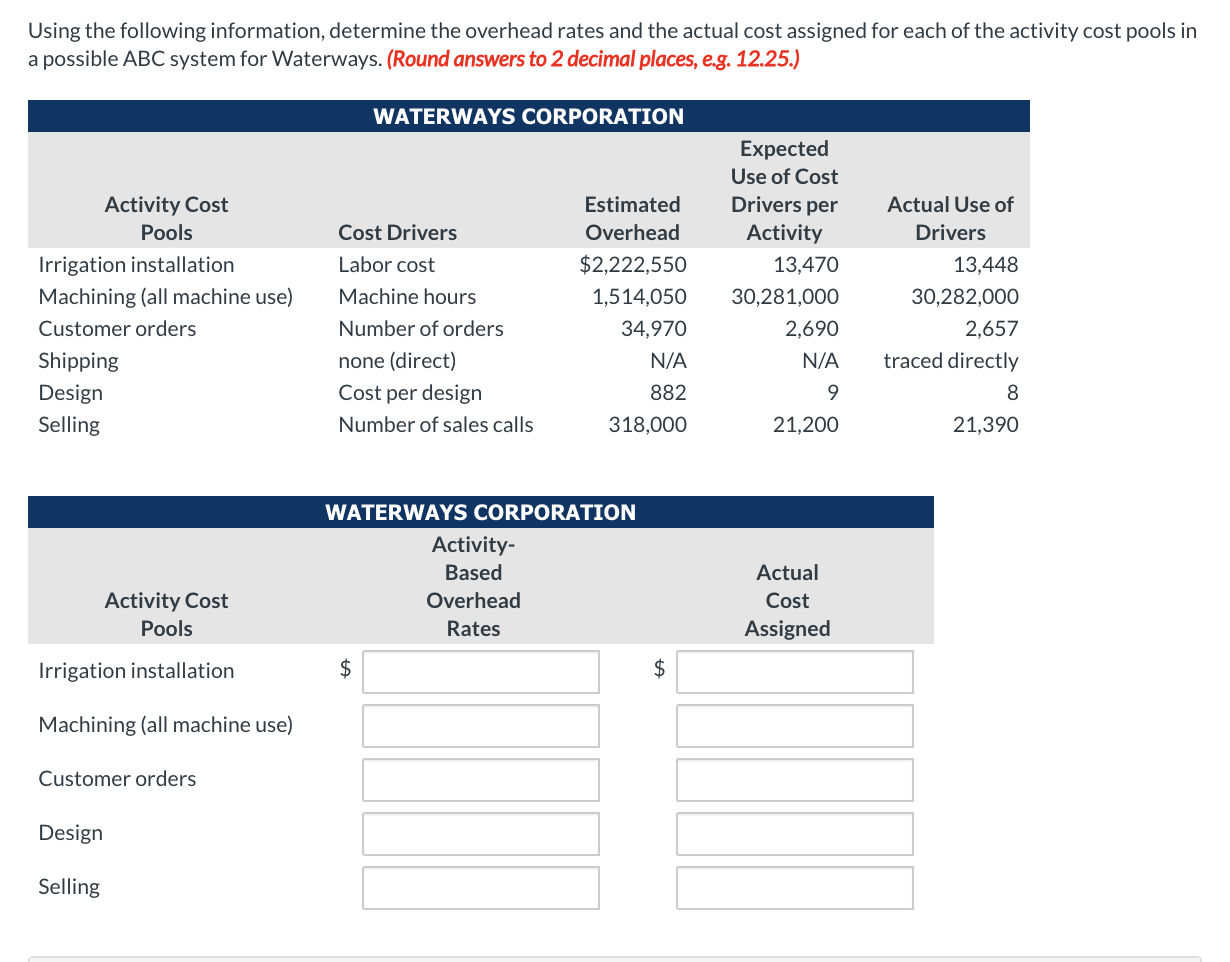

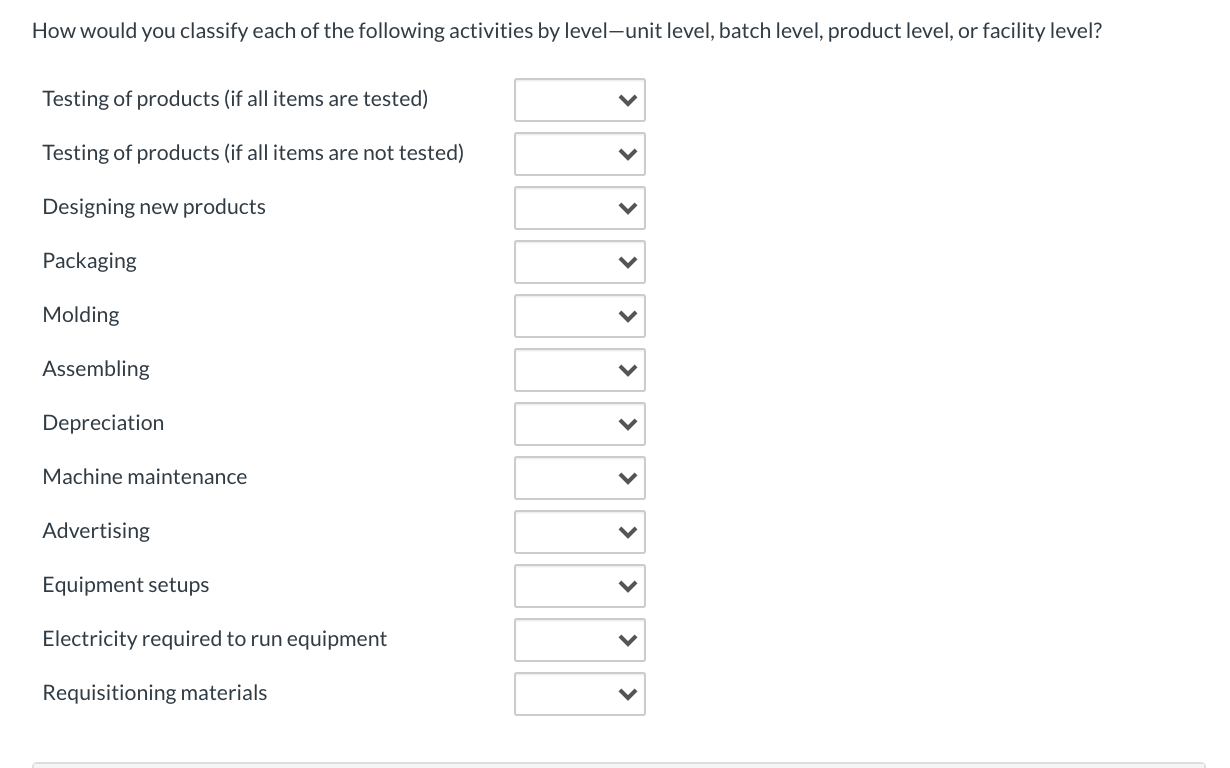

Direct labor or machine hours may not be the appropriate cost driver for overhead in all areas of manufacturing due to the complexities of many manufacturing processes. Many companies use activity-based costing (ABC) which uses multiple drivers (items that consume resources) rather than just one driver to apply overhead to their activities. With ABC, a company can use a cost driver that has a direct cause/effect relationship in its applied overhead costs. Waterways looked into ABC as a method of costing because of the variety of items it produces and the many different activities in which it is involved. The activities listed below area sample of possible cost pools for Waterways.

Step by Step Solution

There are 3 Steps involved in it

Step: 1

Get Instant Access to Expert-Tailored Solutions

See step-by-step solutions with expert insights and AI powered tools for academic success

Step: 2

Step: 3

Ace Your Homework with AI

Get the answers you need in no time with our AI-driven, step-by-step assistance

Get Started