Answered step by step

Verified Expert Solution

Question

1 Approved Answer

Dried sugar cane billets are shredded and conveyed to a diffuser, which consists of a stainless steel mesh conveyor belt on which the shredded solids

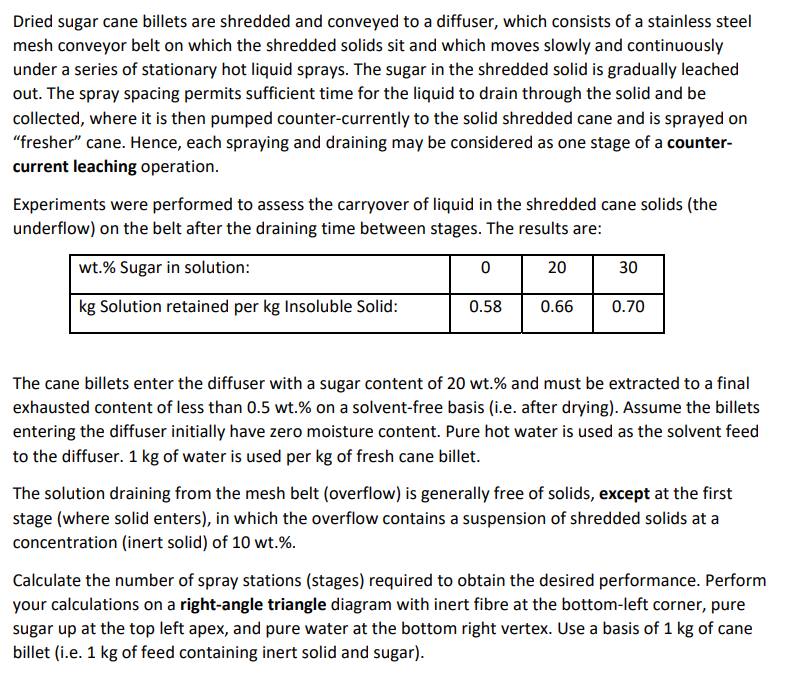

Dried sugar cane billets are shredded and conveyed to a diffuser, which consists of a stainless steel

mesh conveyor belt on which the shredded solids sit and which moves slowly and continuously

under a series of stationary hot liquid sprays. The sugar in the shredded solid is gradually leached

out. The spray spacing permits sufficient time for the liquid to drain through the solid and be

collected, where it is then pumped countercurrently to the solid shredded cane and is sprayed on

"fresher" cane. Hence, each spraying and draining may be considered as one stage of a counter

current leaching operation.

Experiments were performed to assess the carryover of liquid in the shredded cane solids the

underflow on the belt after the draining time between stages. The results are:

The cane billets enter the diffuser with a sugar content of and must be extracted to a final

exhausted content of less than on a solventfree basis ie after drying Assume the billets

entering the diffuser initially have zero moisture content. Pure hot water is used as the solvent feed

to the diffuser. of water is used per of fresh cane billet.

The solution draining from the mesh belt overflow is generally free of solids, except at the first

stage where solid enters in which the overflow contains a suspension of shredded solids at a

concentration inert solid of

Calculate the number of spray stations stages required to obtain the desired performance. Perform

your calculations on a rightangle triangle diagram with inert fibre at the bottomleft corner, pure

sugar up at the top left apex, and pure water at the bottom right vertex. Use a basis of of cane

billet ie of feed containing inert solid and sugar

Step by Step Solution

There are 3 Steps involved in it

Step: 1

Get Instant Access to Expert-Tailored Solutions

See step-by-step solutions with expert insights and AI powered tools for academic success

Step: 2

Step: 3

Ace Your Homework with AI

Get the answers you need in no time with our AI-driven, step-by-step assistance

Get Started