Answered step by step

Verified Expert Solution

Question

1 Approved Answer

Equipment design for process given the following description. Mini-Project 20CHME18I 2020/2021 The manufacturing process include equal feed of 150 ton/day of particle size 50 cm

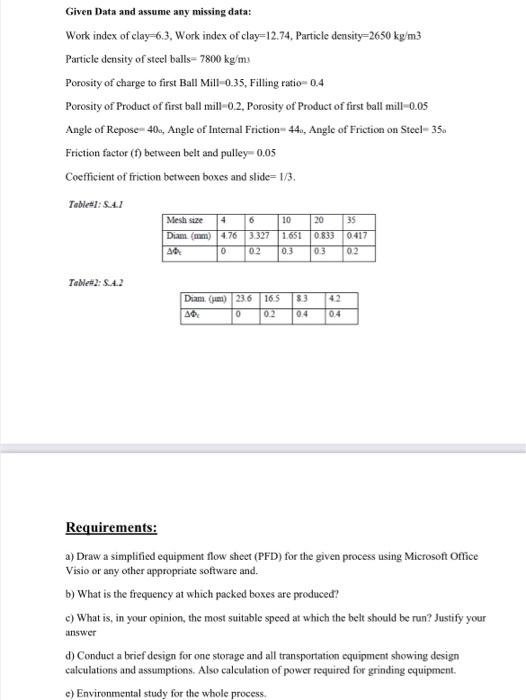

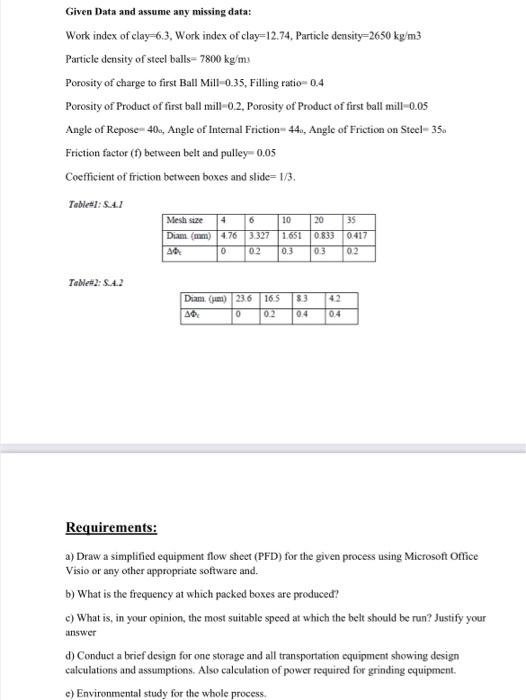

Equipment design for process given the following description. Mini-Project 20CHME18I 2020/2021 The manufacturing process include equal feed of 150 ton/day of particle size 50 cm of clay and 60 cm of lime stone (L.S) these feed are feed to separate jaw crusher and the product from both crushers is screened over an ideal screen, the fraction of oversize in feed to this screen is equal to 0.4 in case of Lime stone and 0.2 in case of clay. The overflow from both screens is recycled to its crusher for further crushing and the product fine product from each screens stored in separate stored tank for 10 hrs after storing the two products are mixed and feed to ball mill (raw mill) with screen analysis (S.A.1, Table#1). The product from the ball mill with screen analysis (S.A.2, Table#2) is then transported using a pneumatic conveyor which uses compressed air. This conveyor conveyed the ground product to 2 identical raw milll silo using horizontal distance of 2 m and vertical distance of 3 m and 2 (90 o ) elbows then conveyed to suspension preheater and rotary kiln and clinker silo and finally to ball mill (cement mill) using conveyor of horizontal distance of 6 m and vertical distance of 10m and 2 (90 o) elbows. Half of fine dry product is packaged and transported to trucks using belt conveyor and the other half is loaded as it on cement tanker. The packing boxes contains 20 kg powder (+500 g for the empty box) of dimensions 500*500*150 mm as shown in following figure.  Given Data and assume any missing data: Work index of clay=6.3. Work index of clay=12.74. Particle density=2650 kg/m3 Particle density of steel balls= 7800 kg/m Porosity of charge to first Ball Mill 0.35, Filling ratio-0.4 Porosity of Product of first ball mill-0.2, Porosity of Product of first ball mill-0.05 Angle of Repose 40a, Angle of Internal Friction - 44., Angle of Friction on Steel - 35. Friction factor (f) between belt and pulley-0.05 Coefficient of friction between boxes and slide=1/3. Tablet): 8.4.1 Mesh size 4 6 Diam(m) 4.76 3.327 AD 0 02 10 1651 03 20 0.833 03 35 0.417 02 Table#2: 5.4.2 83 Diam. (jam) 236 0 103 16 5 02 42 04 04 Requirements: a) Draw a simplified equipment flow sheet (PFD) for the given process using Microsoft Office Visio or any other appropriate software and. b) What is the frequency at which packed boxes are produced? c) What is in your opinion, the most suitable speed at which the belt should be run? Justify your answer d) Conduct a brief design for one storage and all transportation equipment showing design calculations and assumptions. Also calculation of power required for grinding equipment, e) Environmental study for the whole process

Given Data and assume any missing data: Work index of clay=6.3. Work index of clay=12.74. Particle density=2650 kg/m3 Particle density of steel balls= 7800 kg/m Porosity of charge to first Ball Mill 0.35, Filling ratio-0.4 Porosity of Product of first ball mill-0.2, Porosity of Product of first ball mill-0.05 Angle of Repose 40a, Angle of Internal Friction - 44., Angle of Friction on Steel - 35. Friction factor (f) between belt and pulley-0.05 Coefficient of friction between boxes and slide=1/3. Tablet): 8.4.1 Mesh size 4 6 Diam(m) 4.76 3.327 AD 0 02 10 1651 03 20 0.833 03 35 0.417 02 Table#2: 5.4.2 83 Diam. (jam) 236 0 103 16 5 02 42 04 04 Requirements: a) Draw a simplified equipment flow sheet (PFD) for the given process using Microsoft Office Visio or any other appropriate software and. b) What is the frequency at which packed boxes are produced? c) What is in your opinion, the most suitable speed at which the belt should be run? Justify your answer d) Conduct a brief design for one storage and all transportation equipment showing design calculations and assumptions. Also calculation of power required for grinding equipment, e) Environmental study for the whole process

Equipment design for process given the following description.

Mini-Project

20CHME18I

2020/2021

The manufacturing process include equal feed of 150 ton/day of particle size 50 cm of clay and 60 cm of lime stone (L.S) these feed are feed to separate jaw crusher and the product from both crushers is screened over an ideal screen, the fraction of oversize in feed to this screen is equal to 0.4 in case of Lime stone and 0.2 in case of clay. The overflow from both screens is recycled to its crusher for further crushing and the product fine product from each screens stored in separate stored tank for 10 hrs after storing the two products are mixed and feed to ball mill (raw mill) with screen analysis (S.A.1, Table#1). The product from the ball mill with screen analysis (S.A.2, Table#2) is then transported using a pneumatic conveyor which uses compressed air. This conveyor conveyed the ground product to 2 identical raw milll silo using horizontal distance of 2 m and vertical distance of 3 m and 2 (90 o ) elbows then conveyed to suspension preheater and rotary kiln and clinker silo and finally to ball mill (cement mill) using conveyor of horizontal distance of 6 m and vertical distance of 10m and 2 (90 o) elbows. Half of fine dry product is packaged and transported to trucks using belt conveyor and the other half is loaded as it on cement tanker. The packing boxes contains 20 kg powder (+500 g for the empty box) of dimensions 500*500*150 mm as shown in following figure.

Step by Step Solution

There are 3 Steps involved in it

Step: 1

Get Instant Access to Expert-Tailored Solutions

See step-by-step solutions with expert insights and AI powered tools for academic success

Step: 2

Step: 3

Ace Your Homework with AI

Get the answers you need in no time with our AI-driven, step-by-step assistance

Get Started