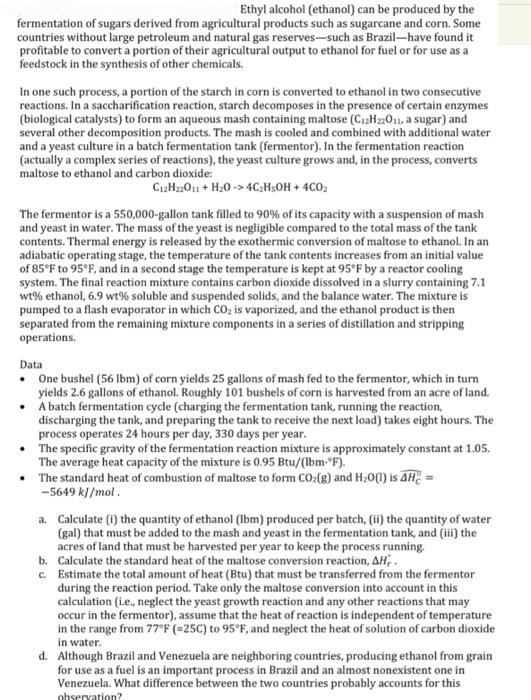

Ethyl alcohol (ethanol) can be produced by the fermentation of sugars derived from agricultural products such as sugarcane and corn. Some countries without large petroleum and natural gas reserves-such as Brazil-have found it profitable to convert a portion of their agricultural output to ethanol for fuel or for use as a feedstock in the synthesis of other chemicals. In one such process, a portion of the starch in corn is converted to ethanol in two consecutive reactions. In a saccharification reaction, starch decomposes in the presence of certain enzymes (biological catalysts) to form an aqueous mash containing maltose (C12H22O11, a sugar) and several other decomposition products. The mash is cooled and combined with additional water and a yeast culture in a batch fermentation tank (fermentor). In the fermentation reaction (actually a complex series of reactions), the yeast culture grows and, in the process, converts maltose to ethanol and carbon dioxide: C12H22O11+H2O4C2H5OH+4CO2 The fermentor is a 550,000 -gallon tank filled to 90% of its capacity with a suspension of mash and yeast in water. The mass of the yeast is negligible compared to the total mass of the tank contents. Thermal energy is released by the exothermic conversion of maltose to ethanol. In an adiabatic operating stage, the temperature of the tank contents increases from an initial value of 85F to 95F, and in a second stage the temperature is kept at 95F by a reactor cooling system. The final reaction mixture contains carbon dioxide dissolved in a slurry containing 7,1 wt\% ethanol, 6.9 wt % soluble and suspended solids, and the balance water. The mixture is pumped to a flash evaporator in which CO2 is vaporized, and the ethanol product is then separated from the remaining mixture components in a series of distillation and stripping operations. Data - One bushel ( 56lbm ) of corn yields 25 gallons of mash fed to the fermentor, which in turn yields 2.6 gallons of ethanol. Roughly 101 bushels of corn is harvested from an acre of land. - A batch fermentation cycle (charging the fermentation tank, running the reaction, discharging the tank, and preparing the tank to receive the next load) takes eight hours. The process operates 24 hours per day, 330 days per year. - The specific gravity of the fermentation reaction mixture is approximately constant at 1.05. The average heat capacity of the mixture is 0.95Btu/(lbmF). - The standard heat of combustion of maltose to form CO2(g) and H2O(I) is HC= 5649kJ/mol. a. Calculate (i) the quantity of ethanol (Ibm) produced per batch, (ii) the quantity of water (gal) that must be added to the mash and yeast in the fermentation tank, and (iii) the acres of land that must be harvested per year to keep the process running. b. Calculate the standard heat of the maltose conversion reaction, Hr. c. Estimate the total amount of heat (Btu) that must be transferred from the fermentor during the reaction period. Take only the maltose conversion into account in this calculation (i.e., neglect the yeast growth reaction and any other reactions that may occur in the fermentor), assume that the heat of reaction is independent of temperature in the range from 77F(=25C) to 95F, and neglect the heat of solution of carbon dioxide in water. d. Although Brazil and Venezuela are neighboring countries, producing ethanol from grain for use as a fuel is an important process in Brazil and an almost nonexistent one in Venezuela. What difference between the two countries probably accounts for this