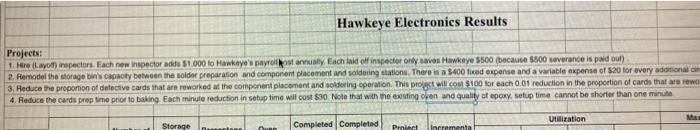

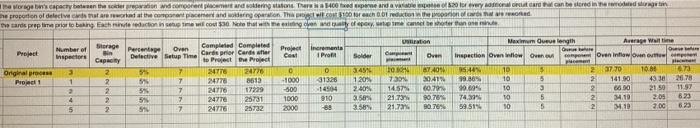

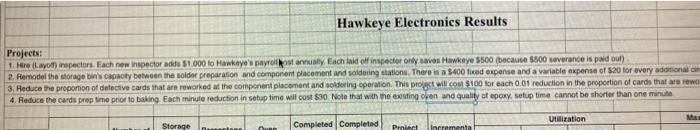

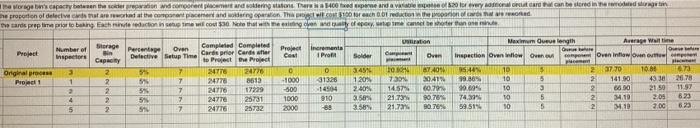

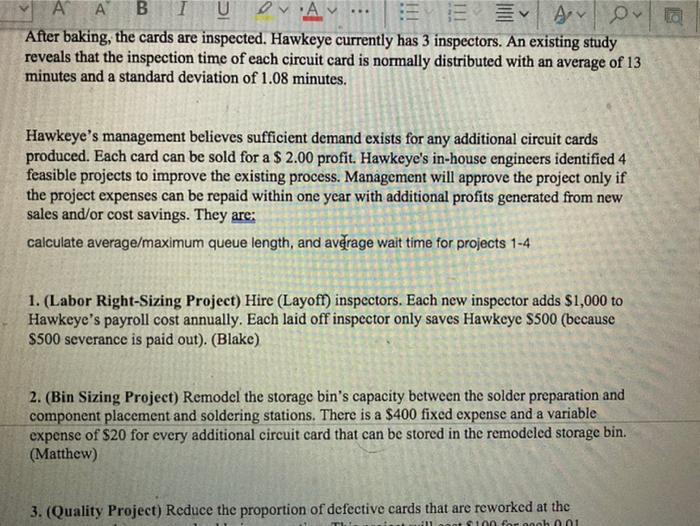

Evaluate project 1's process metrics; i.e. maximum queue length, average wait time, and utilization of each step in the process. Discuss the tradoffs (process metrics versus cost versus profits) and decide the best number for project 1.

use the information from the charts to find the average/maximum queue length, average wait time, and utilization for each step of project one

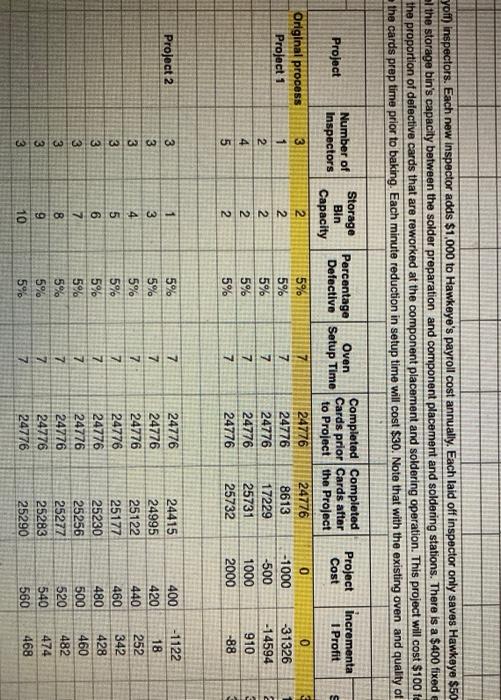

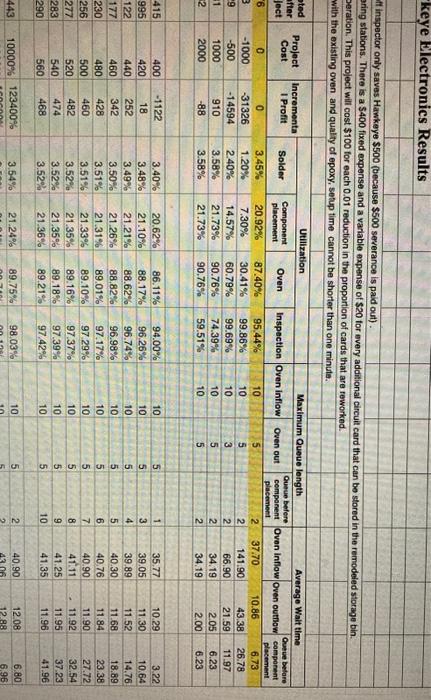

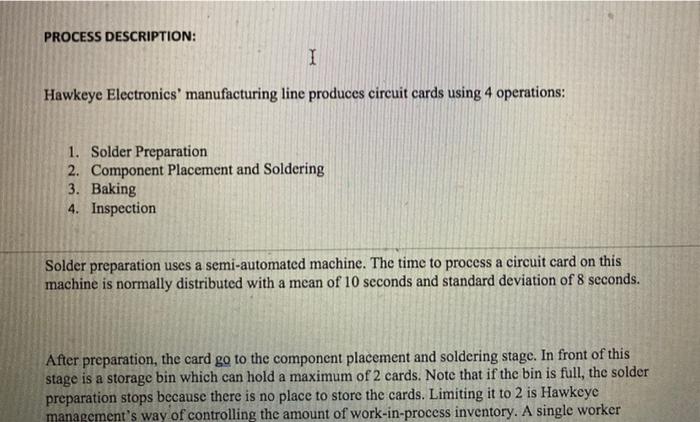

Hawkeye Electronics Results Projects: 1. Hra layof) inspectors. Each new inspector add $1,000 to Hawkeye's payrols anually. Each laid off inspector only waven Hawkeye 5500 (because $500 severance is paid out) 2. Remodel the storage bincapaoty between the soldar preparation and component placement and soldering station. There is a $400 fixed expense and a variable expense of $20 for every actional.com 3. Reduce the proportion of detective cards that are worked at the component placement and soldering operation. This project will con $100 for each 0.01 reduction in the proportion of cards that are rowo 4. Reduce the cards prep time prior to baking Each minute reduction in setup time will cost $30. Note that with the existing oven and quality of epoxy, setup time cannot be shorter than one minute Utilization Mas Storage Completed Completed Proiect Incrementa a worse's capacity ben the rain componenter som er 1400 de and a 520 or you and can be stored in andere che proportion of elected the pace and daring operation The Orchard the tards propte prior to the reduction is new cout 80. The work can beter Union Sorge Per Projek Terment Cest Pro Solder Our Number of Project Inspectors Original proces 3 Project 1 2 4 5 Capacity 2 2 2 2 2 Oven Completed Completed Detective etup Time Cards Cardewer to Projecte Pro 54 2478 20776 54 7 24778 361 5% 7 24776 17229 59 2477 25731 7 24776 25732 O 1000 -500 1000 2000 WEL 0 31326 -14504 910 -88 3499 1 20% 20% 3.56 35 7304 14573 2175 21.7 Maximum de longi Average Wall G Que Inspection Oven wow On conveniowOven om 5449 3 3770 1066 1673 1988 10 5 1410 433 24178 10.89 10 a 6800 2150 11.7 74.37 10 5 2 34.0 2.01 623 59519 5 2 HD 2.00 6.23 87 40 20415 0.79 BO 90.70 8. PROCESS DESCRIPTION: I Hawkeye Electronics' manufacturing line produces circuit cards using 4 operations: 1. Solder Preparation 2. Component Placement and Soldering 3. Baking 4. Inspection Solder preparation uses a semi-automated machine. The time to process a circuit card on this machine is normally distributed with a mean of 10 seconds and standard deviation of 8 seconds. After preparation, the card go to the component placement and soldering stage. In front of this stage is a storage bin which can hold a maximum of 2 cards. Note that if the bin is full, the solder preparation stops because there is no place to store the cards. Limiting it to 2 is Hawkeye management's way of controlling the amount of work-in-process inventory. A single worker ' ' .. v Aroul After preparation, the card go to the component placement and soldering stage. In front of this stage is a storage bin which can hold a maximum of 2 cards. Note that if the bin is full, the solder preparation stops because there is no place to store the cards. Limiting it to 2 is Hawkeye management's way of controlling the amount of work-in-process inventory. A single worker manually performs the component placement and soldering operation. A study shows that the component placement time of each circuit card is normally distributed with mean processing time of 1.0 minute and a standard deviation of 0.108 minute. The worker is responsible for the quality of his work. He visually inspects each card and repairs it if defective. The repair time is also normally distributed with an average of 40 minutes and a standard deviation of 1.080 minute. About 5% of the cards is expected to be defective. After soldering the components, there is a storage bin which can hold a maximum of 10 cards. Circuit boards are prepared (setup) for baking. The oven's capacity is 5 cards. To load the oven, boards are coated with epoxy and vertically stacked in a metal tray that slides out of the oven. This takes 7 minutes. Baking takes exactly 15 minutes. After baking, the cards are inspected. Hawkeye currently has 3 inspectors. An existing study reveals that the inspection time of each circuit card is normally distributed with an average of 13 minutes and a standard deviation of 1.08 minutes. Hueye's management helicyes sufficient demand exists for any additional circuit cards | Avlova A A BI U OVA... E After baking, the cards are inspected. Hawkeye currently has 3 inspectors. An existing study reveals that the inspection time of each circuit card is normally distributed with an average of 13 minutes and a standard deviation of 1.08 minutes. Hawkeye's management believes sufficient demand exists for any additional circuit cards produced. Each card can be sold for a $ 2.00 profit. Hawkeye's in-house engineers identified 4 feasible projects to improve the existing process. Management will approve the project only if the project expenses can be repaid within one year with additional profits generated from new sales and/or cost savings. They are: calculate average/maximum queue length, and average wait time for projects 1-4 1. (Labor Right-Sizing Project) Hire (Layoff) inspectors. Each new inspector adds $1,000 to Hawkeye's payroll cost annually. Each laid off inspector only saves Hawkeye $500 (because $500 severance is paid out). (Blake) 2. (Bin Sizing Project) Remodel the storage bin's capacity between the solder preparation and component placement and soldering stations. There is a $400 fixed expense and a variable expense of $20 for every additional circuit card that can be stored in the remodeled storage bin. (Matthew) 3. (Quality Project) Reduce the proportion of defective cards that are reworked at the 10 fok 1 yoff) inspectors. Each new inspector adds $1,000 to Hawkeye's payroll cost annually. Each laid off inspector only saves Hawkeye $50 el the storage bin's capacity between the solder preparation and component placement and soldering stations. There is a $400 fixed the proportion of defective cards that are reworked at the component placement and soldering operation. This project will cost $100 fe the cards prep time prior to baking. Each minute reduction in setup time will cost $30. Note that with the existing oven and quality of Number of Inspectors Project Storage Bin Capacity Project Cost Incrementa I Profit 3 0 Original process Project 1 Percentage Completed Completed Oven Defective Setup Time Cards prior Cards after to Project the Project 5% 7 24776 24776 5% 7 24776 8613 5% 7 24776 17229 5% 7 24776 25731 5% 7 24776 25732 1 2 4 5 NNNNN -1000 -500 1000 2000 0 -31326 -14594 910 -88 Project 2 1 3 4 7 7 7 7 5 5% 5% 5% 5% 5% 5% 5% 5% 5% 6 7 7 24776 24776 24776 24776 24776 24776 24776 24776 24776 24415 24995 25122 25177 25230 25256 25277 25283 25290 400 420 440 460 480 500 520 540 560 -1122 18 252 342 428 460 482 474 468 7 B 7 9 10 7 7 -keye Electronics Results of inspector only savas Hawkeye $500 (because $500 severance is paid out) Bring stations. There is a $400 fixed expense and a variable expense of $20 for every additional circuit card that can be stored in the remodeled storage bin. Deration. This project will cost $100 for each 0.01 reduction in the proportion of cards that are reworked with the existing oven and quality of epoxy, setup time cannot be shorter than one minute. ated after Project Cost Incrementa I Profit Solder ject "6 3 -9 1 2 0 -1000 -500 1000 2000 0 -31326 -14594 910 -88 3.45% 1.20% 2.40% 3.58% 3.58% Utilization Component Oven placement 20.92% 87.40% 7.30% 30.41% 14.57% 60.79% 21.73% 90.76% 21.73% 90.76% Maximum Queue length Average Walt time Queue before Gure before Inspection Oven inflow Oven out component Oven inflow Oven outflow component placement placement 95.44% 10 5 37.70 10.86 6.73 99.86% 10 5 141.90 43.38 26.78 99.69% 10 3 66.90 21.59 11.97 74.39% 10 5 34.19 2.05 6.23 59.51% 10 5 34.19 2.00 6.23 NNNNN 5 5 5 1 3 4 5 415 995 122 177 230 256 277 283 290 400 420 440 460 480 500 520 540 560 -1122 18 252 342 428 460 482 474 468 3.40% 3.48% 3.49% 3.50% 3.51% 3.51% 3.52% 3.52% 3.52 20.62% 21.10% 21.21% 21.26% 21.3196 21.33% 21.35% 21.35% 21.36% 86.11% 88.17% 88.62% % 88.82% 89.01% 89.10% 89.16% 89.18% 89.21% 94.00% 96.26% 96.74% 96.98% 97.17% 97 29% 97.37% 97.39% 97,426 10 10 10 10 10 10 10 10 10 5 5 5 5 5 5 6 7 8 9 10 35.77 39.05 39.89 40.30 40.76 40.90 41:11 41.25 41.35 10.29 11.30 11.52 11.68 11.84 11.90 11.92 11.95 11.96 3.22 10.64 14.76 18.89 23.38 27.72 32.54 37.23 41.96 443 21.24% 3.54% 10000% 123400% 89.75% 2 98,03% 5 10 40.90 43 06 12.08 12.88 6.80 6.96 5 Hawkeye Electronics Results Projects: 1. Hra layof) inspectors. Each new inspector add $1,000 to Hawkeye's payrols anually. Each laid off inspector only waven Hawkeye 5500 (because $500 severance is paid out) 2. Remodel the storage bincapaoty between the soldar preparation and component placement and soldering station. There is a $400 fixed expense and a variable expense of $20 for every actional.com 3. Reduce the proportion of detective cards that are worked at the component placement and soldering operation. This project will con $100 for each 0.01 reduction in the proportion of cards that are rowo 4. Reduce the cards prep time prior to baking Each minute reduction in setup time will cost $30. Note that with the existing oven and quality of epoxy, setup time cannot be shorter than one minute Utilization Mas Storage Completed Completed Proiect Incrementa a worse's capacity ben the rain componenter som er 1400 de and a 520 or you and can be stored in andere che proportion of elected the pace and daring operation The Orchard the tards propte prior to the reduction is new cout 80. The work can beter Union Sorge Per Projek Terment Cest Pro Solder Our Number of Project Inspectors Original proces 3 Project 1 2 4 5 Capacity 2 2 2 2 2 Oven Completed Completed Detective etup Time Cards Cardewer to Projecte Pro 54 2478 20776 54 7 24778 361 5% 7 24776 17229 59 2477 25731 7 24776 25732 O 1000 -500 1000 2000 WEL 0 31326 -14504 910 -88 3499 1 20% 20% 3.56 35 7304 14573 2175 21.7 Maximum de longi Average Wall G Que Inspection Oven wow On conveniowOven om 5449 3 3770 1066 1673 1988 10 5 1410 433 24178 10.89 10 a 6800 2150 11.7 74.37 10 5 2 34.0 2.01 623 59519 5 2 HD 2.00 6.23 87 40 20415 0.79 BO 90.70 8. PROCESS DESCRIPTION: I Hawkeye Electronics' manufacturing line produces circuit cards using 4 operations: 1. Solder Preparation 2. Component Placement and Soldering 3. Baking 4. Inspection Solder preparation uses a semi-automated machine. The time to process a circuit card on this machine is normally distributed with a mean of 10 seconds and standard deviation of 8 seconds. After preparation, the card go to the component placement and soldering stage. In front of this stage is a storage bin which can hold a maximum of 2 cards. Note that if the bin is full, the solder preparation stops because there is no place to store the cards. Limiting it to 2 is Hawkeye management's way of controlling the amount of work-in-process inventory. A single worker ' ' .. v Aroul After preparation, the card go to the component placement and soldering stage. In front of this stage is a storage bin which can hold a maximum of 2 cards. Note that if the bin is full, the solder preparation stops because there is no place to store the cards. Limiting it to 2 is Hawkeye management's way of controlling the amount of work-in-process inventory. A single worker manually performs the component placement and soldering operation. A study shows that the component placement time of each circuit card is normally distributed with mean processing time of 1.0 minute and a standard deviation of 0.108 minute. The worker is responsible for the quality of his work. He visually inspects each card and repairs it if defective. The repair time is also normally distributed with an average of 40 minutes and a standard deviation of 1.080 minute. About 5% of the cards is expected to be defective. After soldering the components, there is a storage bin which can hold a maximum of 10 cards. Circuit boards are prepared (setup) for baking. The oven's capacity is 5 cards. To load the oven, boards are coated with epoxy and vertically stacked in a metal tray that slides out of the oven. This takes 7 minutes. Baking takes exactly 15 minutes. After baking, the cards are inspected. Hawkeye currently has 3 inspectors. An existing study reveals that the inspection time of each circuit card is normally distributed with an average of 13 minutes and a standard deviation of 1.08 minutes. Hueye's management helicyes sufficient demand exists for any additional circuit cards | Avlova A A BI U OVA... E After baking, the cards are inspected. Hawkeye currently has 3 inspectors. An existing study reveals that the inspection time of each circuit card is normally distributed with an average of 13 minutes and a standard deviation of 1.08 minutes. Hawkeye's management believes sufficient demand exists for any additional circuit cards produced. Each card can be sold for a $ 2.00 profit. Hawkeye's in-house engineers identified 4 feasible projects to improve the existing process. Management will approve the project only if the project expenses can be repaid within one year with additional profits generated from new sales and/or cost savings. They are: calculate average/maximum queue length, and average wait time for projects 1-4 1. (Labor Right-Sizing Project) Hire (Layoff) inspectors. Each new inspector adds $1,000 to Hawkeye's payroll cost annually. Each laid off inspector only saves Hawkeye $500 (because $500 severance is paid out). (Blake) 2. (Bin Sizing Project) Remodel the storage bin's capacity between the solder preparation and component placement and soldering stations. There is a $400 fixed expense and a variable expense of $20 for every additional circuit card that can be stored in the remodeled storage bin. (Matthew) 3. (Quality Project) Reduce the proportion of defective cards that are reworked at the 10 fok 1 yoff) inspectors. Each new inspector adds $1,000 to Hawkeye's payroll cost annually. Each laid off inspector only saves Hawkeye $50 el the storage bin's capacity between the solder preparation and component placement and soldering stations. There is a $400 fixed the proportion of defective cards that are reworked at the component placement and soldering operation. This project will cost $100 fe the cards prep time prior to baking. Each minute reduction in setup time will cost $30. Note that with the existing oven and quality of Number of Inspectors Project Storage Bin Capacity Project Cost Incrementa I Profit 3 0 Original process Project 1 Percentage Completed Completed Oven Defective Setup Time Cards prior Cards after to Project the Project 5% 7 24776 24776 5% 7 24776 8613 5% 7 24776 17229 5% 7 24776 25731 5% 7 24776 25732 1 2 4 5 NNNNN -1000 -500 1000 2000 0 -31326 -14594 910 -88 Project 2 1 3 4 7 7 7 7 5 5% 5% 5% 5% 5% 5% 5% 5% 5% 6 7 7 24776 24776 24776 24776 24776 24776 24776 24776 24776 24415 24995 25122 25177 25230 25256 25277 25283 25290 400 420 440 460 480 500 520 540 560 -1122 18 252 342 428 460 482 474 468 7 B 7 9 10 7 7 -keye Electronics Results of inspector only savas Hawkeye $500 (because $500 severance is paid out) Bring stations. There is a $400 fixed expense and a variable expense of $20 for every additional circuit card that can be stored in the remodeled storage bin. Deration. This project will cost $100 for each 0.01 reduction in the proportion of cards that are reworked with the existing oven and quality of epoxy, setup time cannot be shorter than one minute. ated after Project Cost Incrementa I Profit Solder ject "6 3 -9 1 2 0 -1000 -500 1000 2000 0 -31326 -14594 910 -88 3.45% 1.20% 2.40% 3.58% 3.58% Utilization Component Oven placement 20.92% 87.40% 7.30% 30.41% 14.57% 60.79% 21.73% 90.76% 21.73% 90.76% Maximum Queue length Average Walt time Queue before Gure before Inspection Oven inflow Oven out component Oven inflow Oven outflow component placement placement 95.44% 10 5 37.70 10.86 6.73 99.86% 10 5 141.90 43.38 26.78 99.69% 10 3 66.90 21.59 11.97 74.39% 10 5 34.19 2.05 6.23 59.51% 10 5 34.19 2.00 6.23 NNNNN 5 5 5 1 3 4 5 415 995 122 177 230 256 277 283 290 400 420 440 460 480 500 520 540 560 -1122 18 252 342 428 460 482 474 468 3.40% 3.48% 3.49% 3.50% 3.51% 3.51% 3.52% 3.52% 3.52 20.62% 21.10% 21.21% 21.26% 21.3196 21.33% 21.35% 21.35% 21.36% 86.11% 88.17% 88.62% % 88.82% 89.01% 89.10% 89.16% 89.18% 89.21% 94.00% 96.26% 96.74% 96.98% 97.17% 97 29% 97.37% 97.39% 97,426 10 10 10 10 10 10 10 10 10 5 5 5 5 5 5 6 7 8 9 10 35.77 39.05 39.89 40.30 40.76 40.90 41:11 41.25 41.35 10.29 11.30 11.52 11.68 11.84 11.90 11.92 11.95 11.96 3.22 10.64 14.76 18.89 23.38 27.72 32.54 37.23 41.96 443 21.24% 3.54% 10000% 123400% 89.75% 2 98,03% 5 10 40.90 43 06 12.08 12.88 6.80 6.96 5