expressed in excel

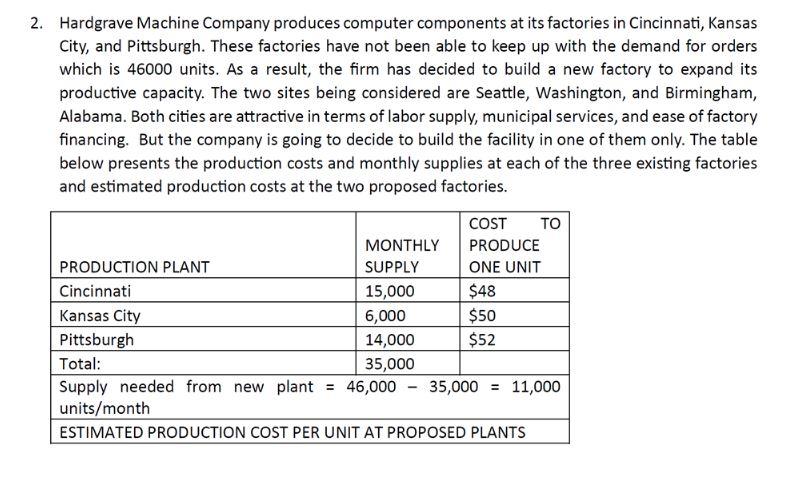

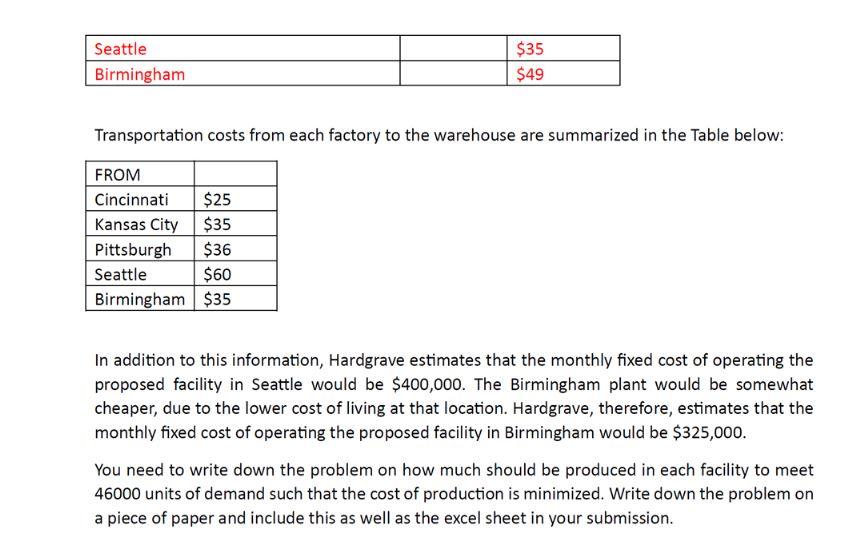

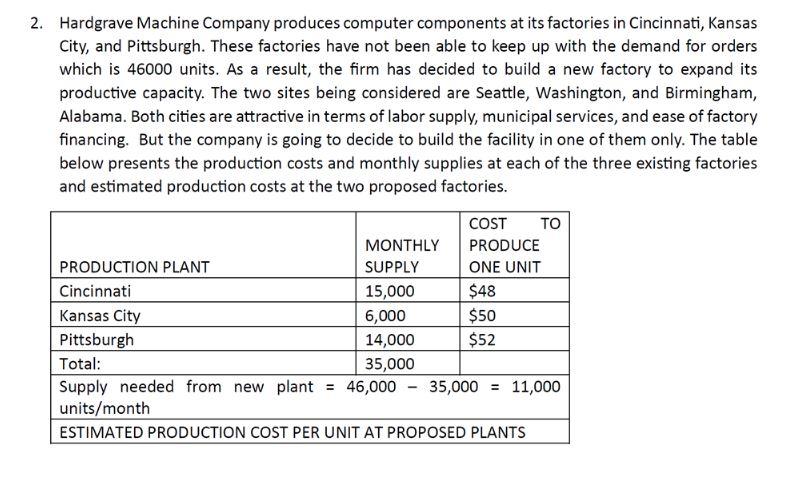

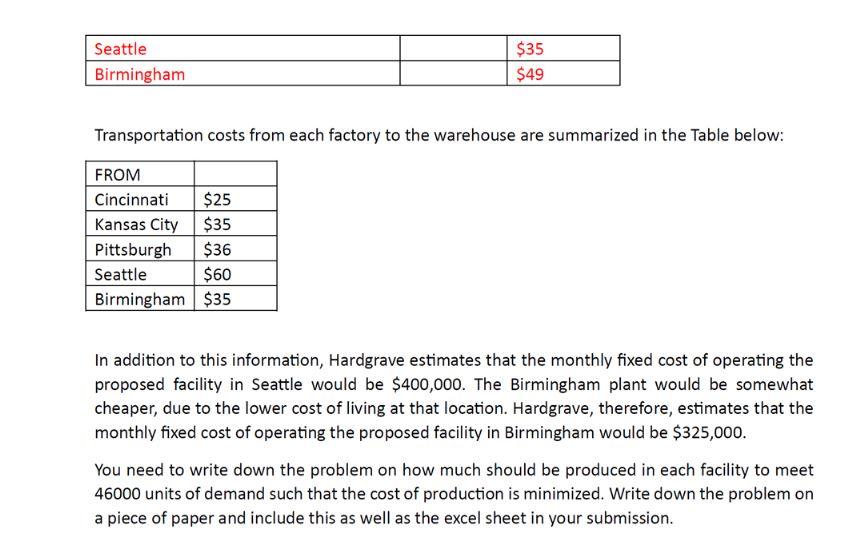

Hardgrave Machine Company produces computer components at its factories in Cincinnati, Kansas City, and Pittsburgh. These factories have not been able to keep up with the demand for orders which is 46000 units. As a result, the firm has decided to build a new factory to expand its productive capacity. The two sites being considered are Seattle, Washington, and Birmingham, Alabama. Both cities are attractive in terms of labor supply, municipal services, and ease of factory financing. But the company is going to decide to build the facility in one of them only. The table below presents the production costs and monthly supplies at each of the three existing factories and estimated production costs at the two proposed factories. Transportation costs from each factory to the warehouse are summarized in the Table below: In addition to this information, Hardgrave estimates that the monthly fixed cost of operating the proposed facility in Seattle would be $400,000. The Birmingham plant would be somewhat cheaper, due to the lower cost of living at that location. Hardgrave, therefore, estimates that the monthly fixed cost of operating the proposed facility in Birmingham would be $325,000. You need to write down the problem on how much should be produced in each facility to meet 46000 units of demand such that the cost of production is minimized. Write down the problem on a piece of paper and include this as well as the excel sheet in your submission. Hardgrave Machine Company produces computer components at its factories in Cincinnati, Kansas City, and Pittsburgh. These factories have not been able to keep up with the demand for orders which is 46000 units. As a result, the firm has decided to build a new factory to expand its productive capacity. The two sites being considered are Seattle, Washington, and Birmingham, Alabama. Both cities are attractive in terms of labor supply, municipal services, and ease of factory financing. But the company is going to decide to build the facility in one of them only. The table below presents the production costs and monthly supplies at each of the three existing factories and estimated production costs at the two proposed factories. Transportation costs from each factory to the warehouse are summarized in the Table below: In addition to this information, Hardgrave estimates that the monthly fixed cost of operating the proposed facility in Seattle would be $400,000. The Birmingham plant would be somewhat cheaper, due to the lower cost of living at that location. Hardgrave, therefore, estimates that the monthly fixed cost of operating the proposed facility in Birmingham would be $325,000. You need to write down the problem on how much should be produced in each facility to meet 46000 units of demand such that the cost of production is minimized. Write down the problem on a piece of paper and include this as well as the excel sheet in your submission