Question: Suppose that you are an analyst for Global, Inc. You have three factories that supply a single product to three warehouses. Your goal is

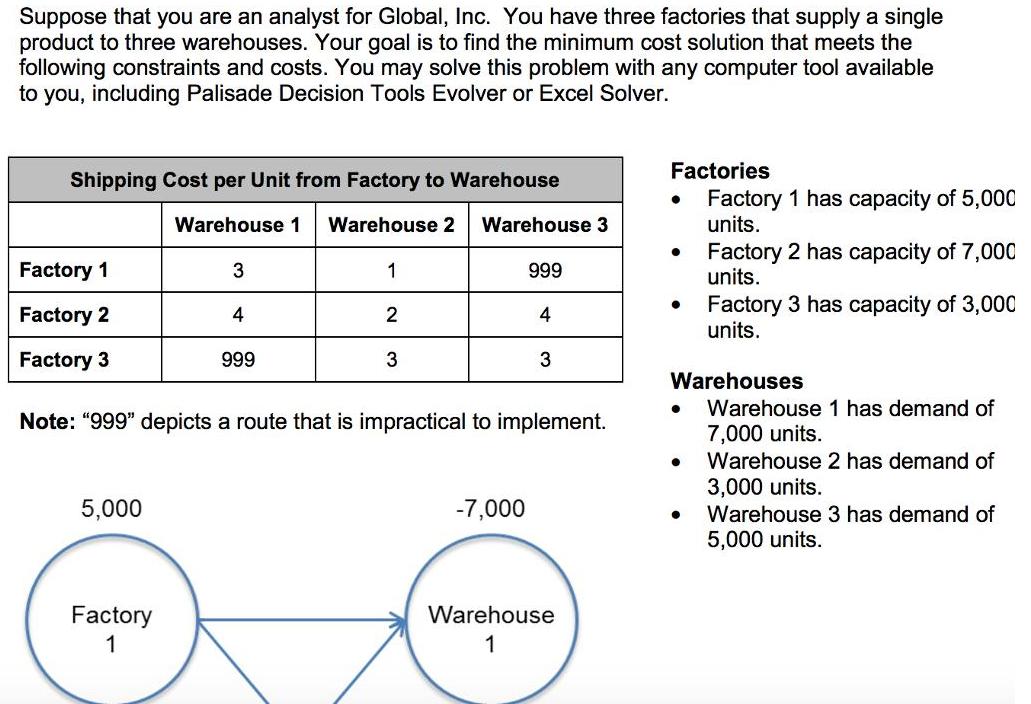

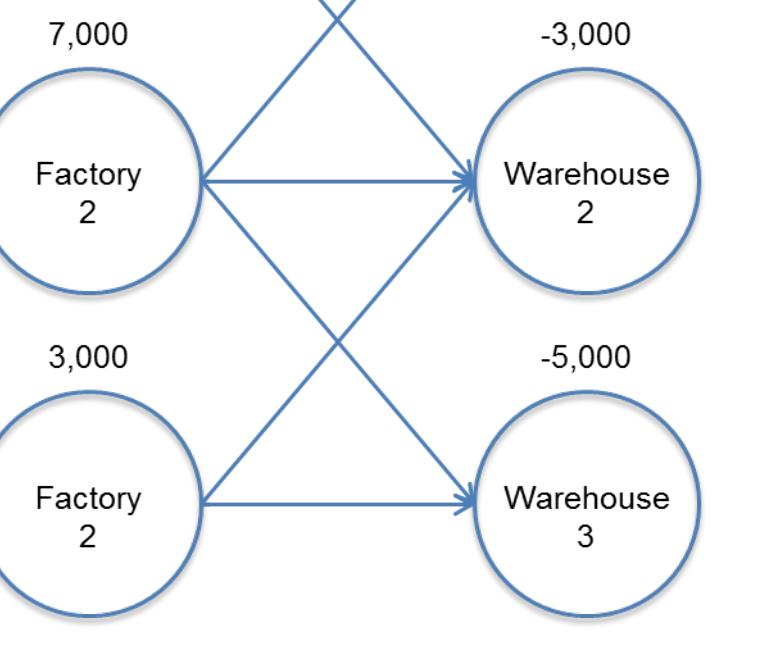

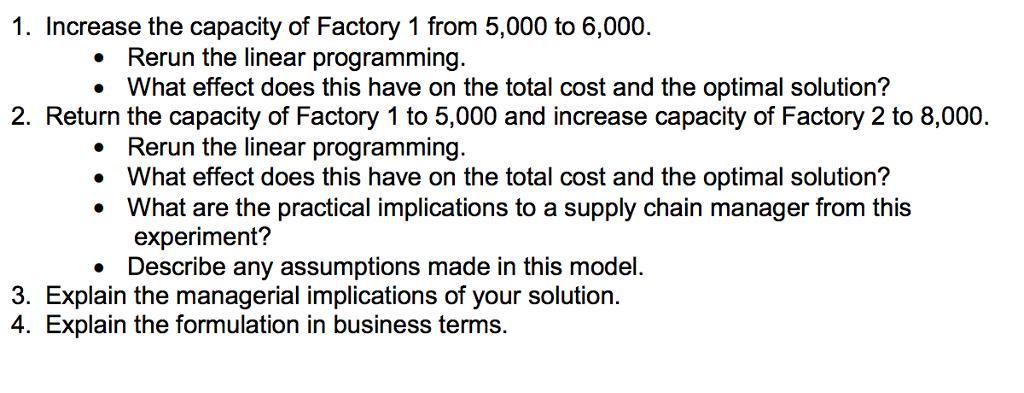

Suppose that you are an analyst for Global, Inc. You have three factories that supply a single product to three warehouses. Your goal is to find the minimum cost solution that meets the following constraints and costs. You may solve this problem with any computer tool available to you, including Palisade Decision Tools Evolver or Excel Solver. Factories Shipping Cost per Unit from Factory to Warehouse Factory 1 has capacity of 5,000 units. Warehouse 1 Warehouse 2 Warehouse 3 Factory 2 has capacity of 7,000 units. Factory 1 3 1 999 Factory 3 has capacity of 3,000 units. Factory 2 4 2 4 Factory 3 999 Warehouses Warehouse 1 has demand of Note: "999" depicts a route that is impractical to implement. 7,000 units. Warehouse 2 has demand of 3,000 units. Warehouse 3 has demand of 5,000 -7,000 5,000 units. Warehouse Factory 1 1 7,000 -3,000 Warehouse Factory 2 2 3,000 -5,000 Factory 2 Warehouse 3 1. Increase the capacity of Factory 1 from 5,000 to 6,000. Rerun the linear programming. What effect does this have on the total cost and the optimal solution? 2. Return the capacity of Factory 1 to 5,000 and increase capacity of Factory 2 to 8,000. Rerun the linear programming. What effect does this have on the total cost and the optimal solution? What are the practical implications to a supply chain manager from this experiment? Describe any assumptions made in this model. 3. Explain the managerial implications of your solution. 4. Explain the formulation in business terms.

Step by Step Solution

3.37 Rating (150 Votes )

There are 3 Steps involved in it

The optimal solution has changed and the cost has decreased 2 The opti... View full answer

Get step-by-step solutions from verified subject matter experts

Document Format (2 attachments)

635df4bfcabc9_180278.pdf

180 KBs PDF File

635df4bfcabc9_180278.docx

120 KBs Word File