Question

Flu Buster Ltd manufactures a type of oral flu vaccine in capsules. These are produced in three separate departments sequentially: Mixing, Encapsulating, and Packaging. The

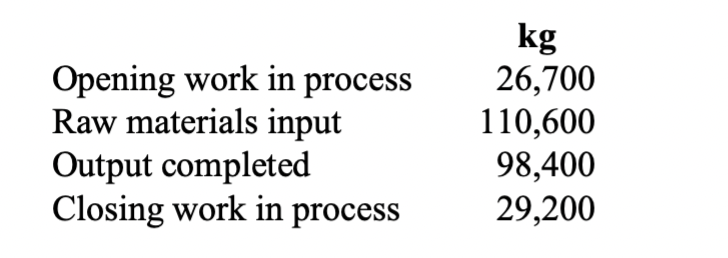

Flu Buster Ltd manufactures a type of oral flu vaccine in capsules. These are produced in three separate departments sequentially: Mixing, Encapsulating, and Packaging. The following information of process inputs, outputs and work in process relates to the Encapsulating department for the month of April 2022:

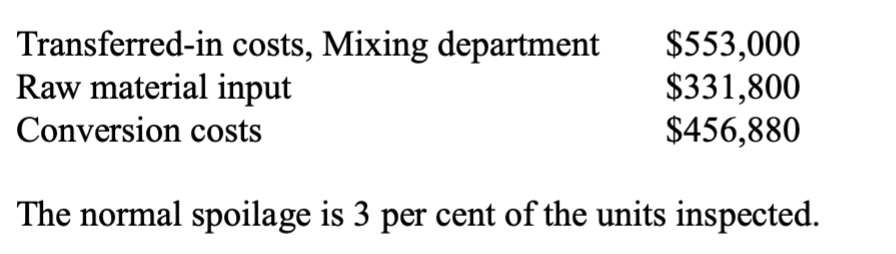

The opening and closing work in process are respectively 50 per cent and 70 per cent complete as to conversion costs. Raw materials are added at the beginning of the manufacturing process. However, conversion costs are incurred evenly throughout the manufacturing process. Spoilages are assumed to occur at the stage of completion where inspection takes place. All spoilages are assumed to be from units started during the month. Inspection takes place when the products are 90% complete. The opening work in process included the transferred-in costs of $200,250 from the Mixing department, raw material costs of $106,800 and conversion costs of $80,100. Costs incurred during the period were:

Assuming that the company uses FIFO method of process costing, use the 4-step approach: (i) Compute the cost per equivalent unit for each product cost category for the month of April. (ii) Calculate the cost of goods transferred to the Packaging department at the end of April. (iii) Calculate the cost of abnormal spoilage in April.

(iv) Calculate the cost of ending work in process in the Encapsulating department at the end of April. (v) Calculate the unit cost of the goods transferred to Packaging department (rounded to 2 decimal places). (vi) Present all the necessary journal entries.

Opening work in process Raw materials input Output completed Closing work in process kg 26,700 110,600 98,400 29,200 Transferred-in costs, Mixing department Raw material input Conversion costs $553,000 $331,800 $456,880 The normal spoilage is 3 per cent of the units inspectedStep by Step Solution

There are 3 Steps involved in it

Step: 1

Get Instant Access to Expert-Tailored Solutions

See step-by-step solutions with expert insights and AI powered tools for academic success

Step: 2

Step: 3

Ace Your Homework with AI

Get the answers you need in no time with our AI-driven, step-by-step assistance

Get Started