Question

Formulate a linear program to determine a production, inventory, distribution, and marketing plan for the next six periods that will ensure profit maximization for IME

Formulate a linear program to determine a production, inventory, distribution, and marketing plan for the next six periods that will ensure profit maximization for IME Inc. Precisely define the decision variables, describe the main goal of the objective function and explain each one of its components and describe each set of constraints. Provide detailed results of your optimal plan using tables and bar charts, including periodic and total profits, revenues, costs, production, storage, labor, raw materials, shipment, and additional demand created from advertising.

Perform sensitivity analysis on labor (regular time), storage capacity, availability of raw materials, and advertising budget. Also, is it profitable to produce all production requirements?

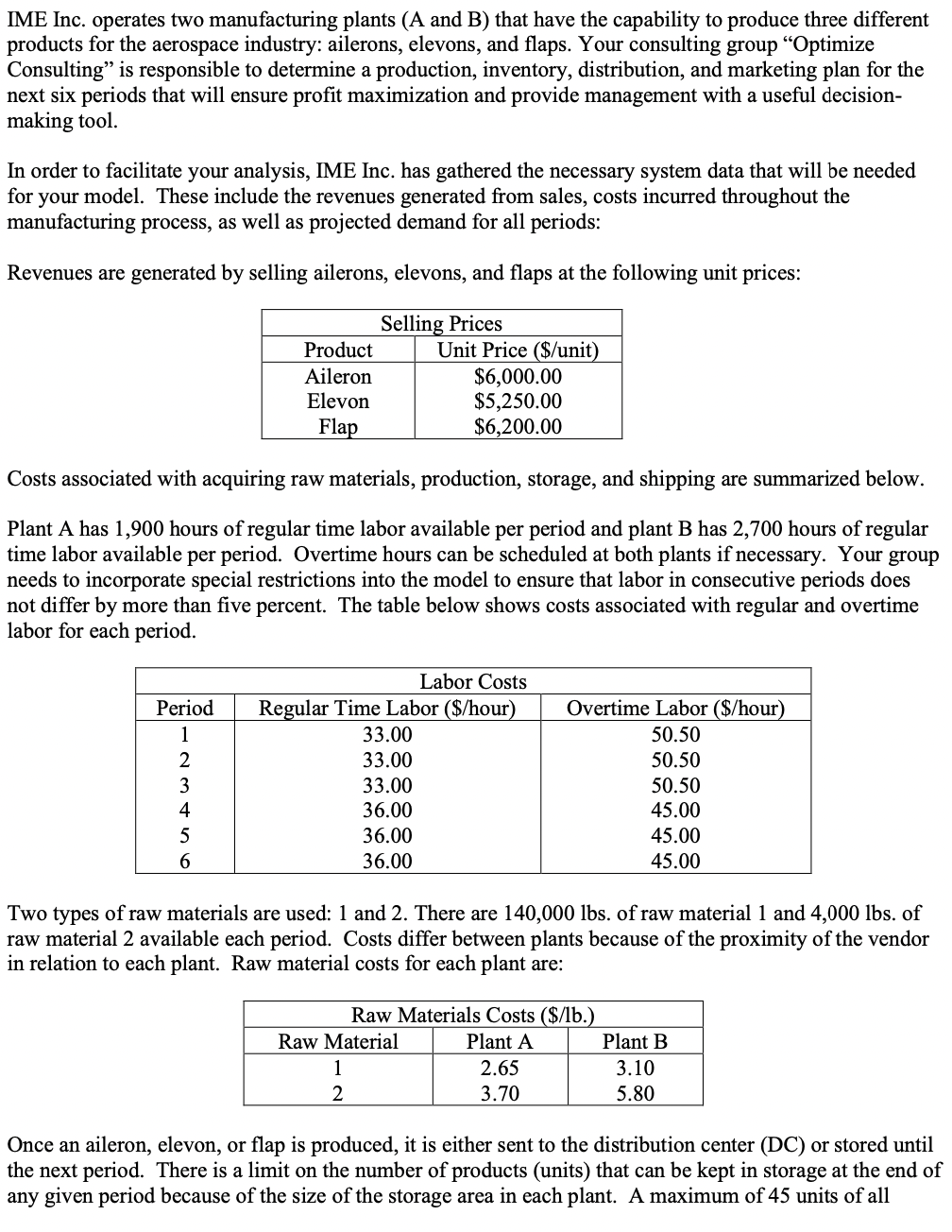

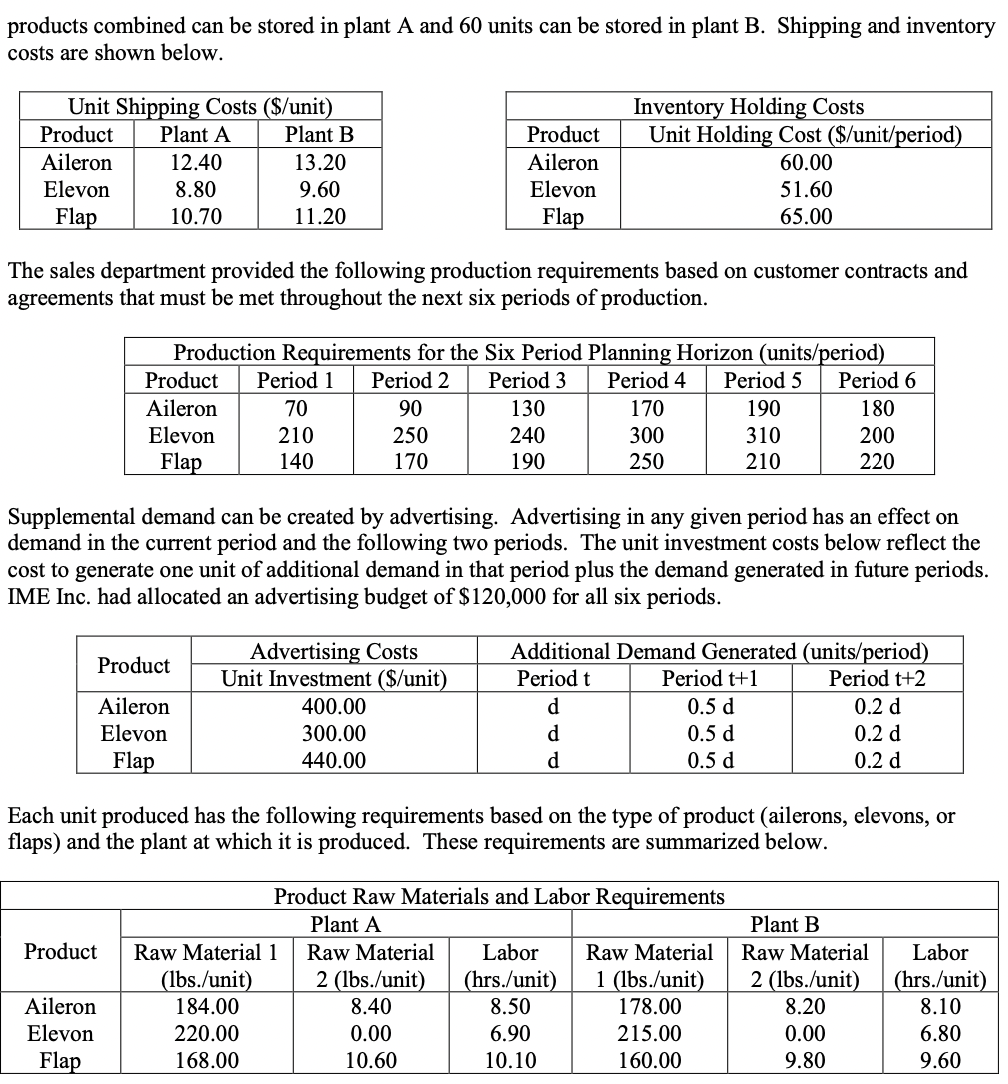

IME Inc. operates two manufacturing plants (A and B) that have the capability to produce three different products for the aerospace industry: ailerons, elevons, and flaps. Your consulting group "Optimize Consulting" is responsible to determine a production, inventory, distribution, and marketing plan for the next six periods that will ensure profit maximization and provide management with a useful decision- making tool. In order to facilitate your analysis, IME Inc. has gathered the necessary system data that will be needed for your model. These include the revenues generated from sales, costs incurred throughout the manufacturing process, as well as projected demand for all periods: Revenues are generated by selling ailerons, elevons, and flaps at the following unit prices: Selling Prices Product Aileron Elevon Flap Period 1 2 3 4 Costs associated with acquiring raw materials, production, storage, and shipping are summarized below. Plant A has 1,900 hours of regular time labor available per period and plant B has 2,700 hours of regular time labor available per period. Overtime hours can be scheduled at both plants if necessary. Your group needs to incorporate special restrictions into the model to ensure that labor in consecutive periods does not differ by more than five percent. The table below shows costs associated with regular and overtime labor for each period. Unit Price ($/unit) $6,000.00 $5,250.00 $6,200.00 Labor Costs Regular Time Labor ($/hour) 33.00 33.00 33.00 36.00 36.00 36.00 Two types of raw materials are used: 1 and 2. There are 140,000 lbs. of raw material 1 and 4,000 lbs. of raw material 2 available each period. Costs differ between plants because of the proximity of the vendor in relation to each plant. Raw material costs for each plant are: 1 2 Overtime Labor ($/hour) 50.50 50.50 50.50 45.00 45.00 45.00 Raw Materials Costs ($/lb.) Raw Material Plant A 2.65 3.70 Plant B 3.10 5.80 Once an aileron, elevon, or flap is produced, it is either sent to the distribution center (DC) or stored until the next period. There is a limit on the number of products (units) that can be kept in storage at the end of any given period because of the size of the storage area in each plant. A maximum of 45 units of all products combined can be stored in plant A and 60 units can be stored in plant B. Shipping and inventory costs are shown below. Unit Shipping Costs ($/unit) Plant B Product Plant A Aileron Elevon Flap 12.40 8.80 10.70 13.20 9.60 11.20 The sales department provided the following production requirements based on customer contracts and agreements that must be met throughout the next six periods of production. Aileron Elevon Flap Product Aileron Elevon Flap Production Requirements for the Six Period Planning Horizon (units/period) Product Period 1 Period 2 Period 3 Period 4 Aileron Elevon Flap 70 210 140 Product Raw Material 1 (lbs./unit) 184.00 220.00 168.00 Product Aileron Elevon Flap 90 250 170 Advertising Costs Unit Investment ($/unit) 400.00 300.00 440.00 Inventory Holding Costs Unit Holding Cost ($/unit/period) 60.00 51.60 65.00 130 240 190 Supplemental demand can be created by advertising. Advertising in any given period has an effect on demand in the current period and the following two periods. The unit investment costs below reflect the cost to generate one unit of additional demand in that period plus the demand generated in future periods. IME Inc. had allocated an advertising budget of $120,000 for all six periods. 170 300 250 d d d Period 5 190 310 210 Additional Demand Generated (units/period) Period t Period t+1 Period t+2 0.5 d 0.5 d 0.5 d Period 6 180 200 220 Product Raw Materials and Labor Requirements Plant A T Each unit produced has the following requirements based on the type of product (ailerons, elevons, or flaps) and the plant at which it is produced. These requirements are summarized below. Raw Material Labor Raw Material 2 (lbs./unit) 1 (lbs./unit) (hrs./unit) 8.50 8.40 178.00 0.00 6.90 215.00 10.60 10.10 160.00 0.2 d 0.2 d 0.2 d Plant B Raw Material 2 (lbs./unit) 8.20 0.00 9.80 Labor (hrs./unit) 8.10 6.80 9.60 IME Inc. operates two manufacturing plants (A and B) that have the capability to produce three different products for the aerospace industry: ailerons, elevons, and flaps. Your consulting group "Optimize Consulting" is responsible to determine a production, inventory, distribution, and marketing plan for the next six periods that will ensure profit maximization and provide management with a useful decision- making tool. In order to facilitate your analysis, IME Inc. has gathered the necessary system data that will be needed for your model. These include the revenues generated from sales, costs incurred throughout the manufacturing process, as well as projected demand for all periods: Revenues are generated by selling ailerons, elevons, and flaps at the following unit prices: Selling Prices Product Aileron Elevon Flap Period 1 2 3 4 Costs associated with acquiring raw materials, production, storage, and shipping are summarized below. Plant A has 1,900 hours of regular time labor available per period and plant B has 2,700 hours of regular time labor available per period. Overtime hours can be scheduled at both plants if necessary. Your group needs to incorporate special restrictions into the model to ensure that labor in consecutive periods does not differ by more than five percent. The table below shows costs associated with regular and overtime labor for each period. Unit Price ($/unit) $6,000.00 $5,250.00 $6,200.00 Labor Costs Regular Time Labor ($/hour) 33.00 33.00 33.00 36.00 36.00 36.00 Two types of raw materials are used: 1 and 2. There are 140,000 lbs. of raw material 1 and 4,000 lbs. of raw material 2 available each period. Costs differ between plants because of the proximity of the vendor in relation to each plant. Raw material costs for each plant are: 1 2 Overtime Labor ($/hour) 50.50 50.50 50.50 45.00 45.00 45.00 Raw Materials Costs ($/lb.) Raw Material Plant A 2.65 3.70 Plant B 3.10 5.80 Once an aileron, elevon, or flap is produced, it is either sent to the distribution center (DC) or stored until the next period. There is a limit on the number of products (units) that can be kept in storage at the end of any given period because of the size of the storage area in each plant. A maximum of 45 units of all products combined can be stored in plant A and 60 units can be stored in plant B. Shipping and inventory costs are shown below. Unit Shipping Costs ($/unit) Plant B Product Plant A Aileron Elevon Flap 12.40 8.80 10.70 13.20 9.60 11.20 The sales department provided the following production requirements based on customer contracts and agreements that must be met throughout the next six periods of production. Aileron Elevon Flap Product Aileron Elevon Flap Production Requirements for the Six Period Planning Horizon (units/period) Product Period 1 Period 2 Period 3 Period 4 Aileron Elevon Flap 70 210 140 Product Raw Material 1 (lbs./unit) 184.00 220.00 168.00 Product Aileron Elevon Flap 90 250 170 Advertising Costs Unit Investment ($/unit) 400.00 300.00 440.00 Inventory Holding Costs Unit Holding Cost ($/unit/period) 60.00 51.60 65.00 130 240 190 Supplemental demand can be created by advertising. Advertising in any given period has an effect on demand in the current period and the following two periods. The unit investment costs below reflect the cost to generate one unit of additional demand in that period plus the demand generated in future periods. IME Inc. had allocated an advertising budget of $120,000 for all six periods. 170 300 250 d d d Period 5 190 310 210 Additional Demand Generated (units/period) Period t Period t+1 Period t+2 0.5 d 0.5 d 0.5 d Period 6 180 200 220 Product Raw Materials and Labor Requirements Plant A T Each unit produced has the following requirements based on the type of product (ailerons, elevons, or flaps) and the plant at which it is produced. These requirements are summarized below. Raw Material Labor Raw Material 2 (lbs./unit) 1 (lbs./unit) (hrs./unit) 8.50 8.40 178.00 0.00 6.90 215.00 10.60 10.10 160.00 0.2 d 0.2 d 0.2 d Plant B Raw Material 2 (lbs./unit) 8.20 0.00 9.80 Labor (hrs./unit) 8.10 6.80 9.60Step by Step Solution

There are 3 Steps involved in it

Step: 1

Get Instant Access to Expert-Tailored Solutions

See step-by-step solutions with expert insights and AI powered tools for academic success

Step: 2

Step: 3

Ace Your Homework with AI

Get the answers you need in no time with our AI-driven, step-by-step assistance

Get Started