Answered step by step

Verified Expert Solution

Question

1 Approved Answer

FutureGas Water Treatment Facility The process of coal seam gas (CSG) extraction involves removing groundwater from a coal seam, reducing the pressure retaining the

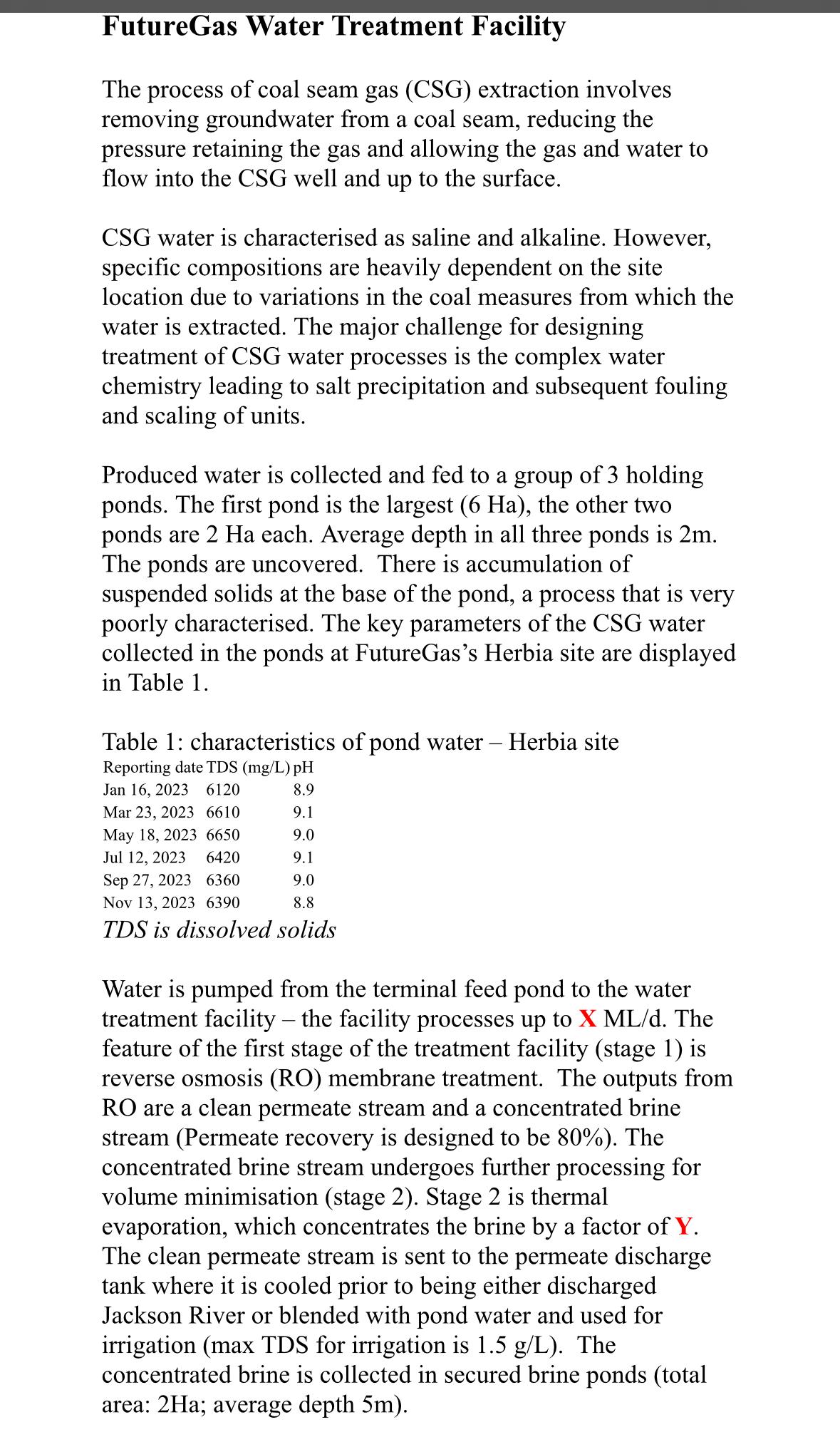

FutureGas Water Treatment Facility The process of coal seam gas (CSG) extraction involves removing groundwater from a coal seam, reducing the pressure retaining the gas and allowing the gas and water to flow into the CSG well and up to the surface. CSG water is characterised as saline and alkaline. However, specific compositions are heavily dependent on the site location due to variations in the coal measures from which the water is extracted. The major challenge for designing treatment of CSG water processes is the complex water chemistry leading to salt precipitation and subsequent fouling and scaling of units. Produced water is collected and fed to a group of 3 holding ponds. The first pond is the largest (6 Ha), the other two ponds are 2 Ha each. Average depth in all three ponds is 2m. The ponds are uncovered. There is accumulation of suspended solids at the base of the pond, a process that is very poorly characterised. The key parameters of the CSG water collected in the ponds at FutureGas's Herbia site are displayed in Table 1. Table 1: characteristics of pond water - Herbia site Reporting date TDS (mg/L) pH Jan 16, 2023 6120 8.9 Mar 23, 2023 6610 9.1 May 18, 2023 6650 9.0 Jul 12, 2023 6420 9.1 Sep 27, 2023 6360 9.0 Nov 13, 2023 6390 8.8 TDS is dissolved solids Water is pumped from the terminal feed pond to the water treatment facility the facility processes up to X ML/d. The feature of the first stage of the treatment facility (stage 1) is reverse osmosis (RO) membrane treatment. The outputs from RO are a clean permeate stream and a concentrated brine stream (Permeate recovery is designed to be 80%). The concentrated brine stream undergoes further processing for volume minimisation (stage 2). Stage 2 is thermal evaporation, which concentrates the brine by a factor of Y. The clean permeate stream is sent to the permeate discharge tank where it is cooled prior to being either discharged Jackson River or blended with pond water and used for irrigation (max TDS for irrigation is 1.5 g/L). The concentrated brine is collected in secured brine ponds (total area: 2Ha; average depth 5m).

Step by Step Solution

There are 3 Steps involved in it

Step: 1

Get Instant Access to Expert-Tailored Solutions

See step-by-step solutions with expert insights and AI powered tools for academic success

Step: 2

Step: 3

Ace Your Homework with AI

Get the answers you need in no time with our AI-driven, step-by-step assistance

Get Started