Answered step by step

Verified Expert Solution

Question

1 Approved Answer

generate a current state Value Stream Map for the TWI Industries product. Please use the following document below as the source data. You are welcome

generate a current state Value Stream Map for the TWI Industries product. Please use the following document below as the source data. You are welcome to draw these maps by hand with paper and pencil or use the computer.

Please make sure each map has material flow, information flow, data boxes, timeline and the percent value add.

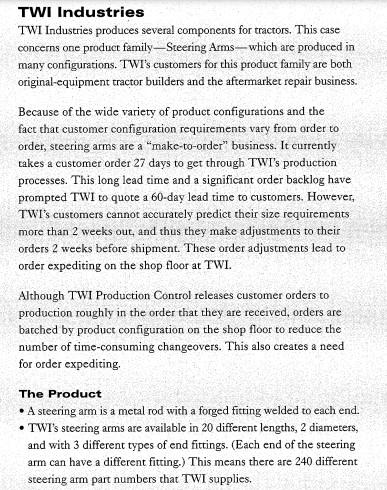

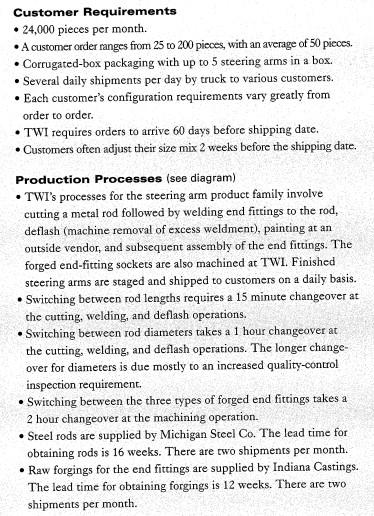

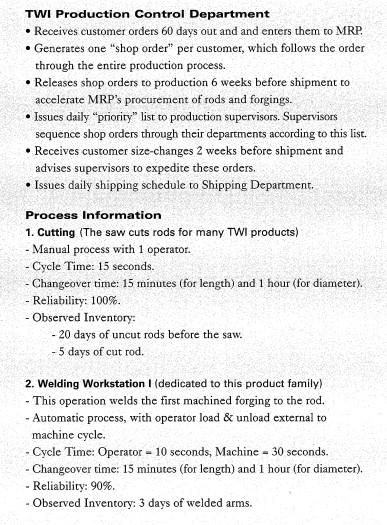

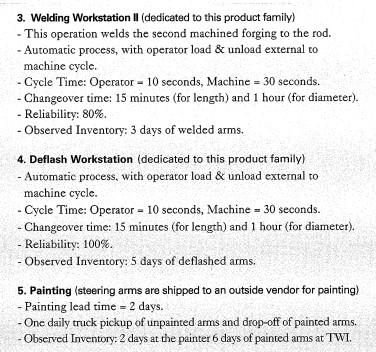

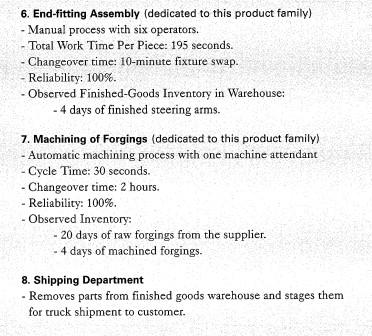

TWI Industries TWI Industries produces several components for tractors. This case concerns one product family-Steering Arms-which are produced in many configurations. TWI's customers for this product family are both original equipment tractor builders and the aftermarket repair business. Because of the wide variety of product configurations and the fact that customer configuration requirements vary from order to order, steering arms are a "make-to-order" business. It currently takes a customer order 27 days to get through TWI's production processes. This long lead time and a significant order backlog have prompted TWI to quote a 60-day lead time to customers. However, TWI's customers cannot accurately predict their size requirements more than 2 weeks out, and thus they make adjustments to their orders 2 weeks before shipment. These order adjustments lead to order expediting on the shop floor at TWI. Although TWI Production Control releases customer orders to production roughly in the order that they are received, orders are batched by product configuration on the shop floor to reduce the number of time-consuming changeovers. This also creates a need for order expediting. The Product A steering arm is a metal rod with a forged fitting welded to each end. TWI's steering arms are available in 20 different lengths, 2 diameters, and with 3 different types of end fittings. (Each end of the steering arm can have a different fitting.) This means there are 240 different steering arm part numbers that TWI supplies.

Step by Step Solution

★★★★★

3.47 Rating (154 Votes )

There are 3 Steps involved in it

Step: 1

Creating a Value Stream Map VSM based on the provided source data would require illustrating the flow of materials and information as they pass throug...

Get Instant Access to Expert-Tailored Solutions

See step-by-step solutions with expert insights and AI powered tools for academic success

Step: 2

Step: 3

Ace Your Homework with AI

Get the answers you need in no time with our AI-driven, step-by-step assistance

Get Started