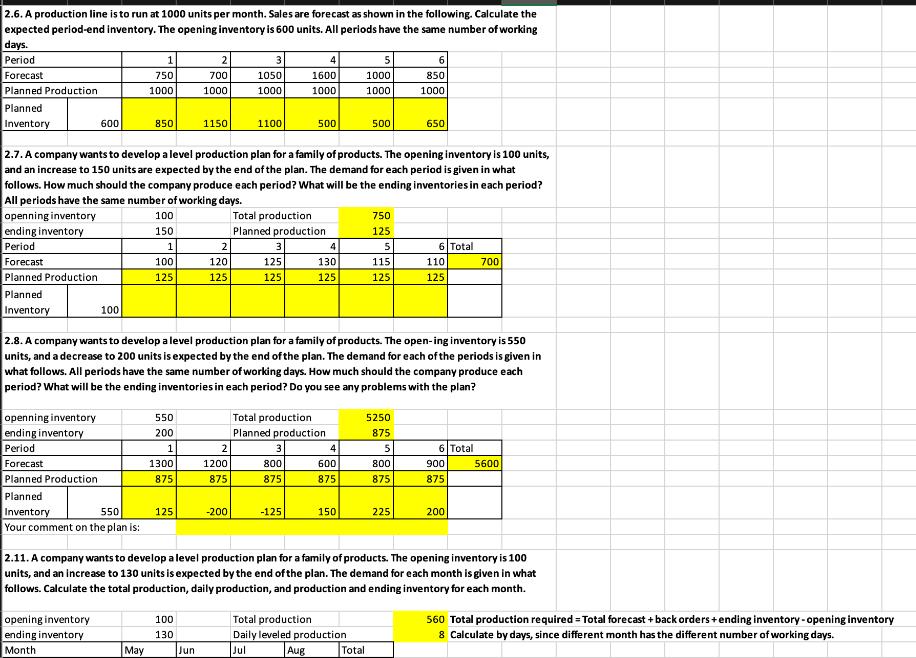

2.6. A production line is to run at 1000 units per month. Sales are forecast as shown in the following. Calculate the expected period-end

2.6. A production line is to run at 1000 units per month. Sales are forecast as shown in the following. Calculate the expected period-end inventory. The opening inventory is 600 units. All periods have the same number of working days. Period Forecast Planned Production Planned Inventory 1 750 2 700 3 4 5 1000 1000 1050 1000 1600 1000 1000 1000 6 850 1000 600 850 1150 1100 500 500 650 2.7. A company wants to develop a level production plan for a family of products. The opening inventory is 100 units, and an increase to 150 units are expected by the end of the plan. The demand for each period is given in what follows. How much should the company produce each period? What will be the ending inventories in each period? All periods have the same number of working days. openning inventory ending inventory Period Forecast Planned Production Planned Inventory 100 100 Total production 750 150 Planned production 125 1 2 3 4 100 120 125 130 5 115 6 Total 110 700 125 125 125 125 125 125 2.8. A company wants to develop a level production plan for a family of products. The open-ing inventory is 550 units, and a decrease to 200 units is expected by the end of the plan. The demand for each of the periods is given in what follows. All periods have the same number of working days. How much should the company produce each period? What will be the ending inventories in each period? Do you see any problems with the plan? openning inventory ending inventory Period Forecast Planned Production 550 Total production 200 Planned production 5250 875 1 2 3 4 5 1300 1200 800 600 800 6 Total 900 5600 875 875 875 875 875 875 Planned Inventory 550 125 -200 -125 150 225 200 Your comment on the plan is: 2.11. A company wants to develop a level production plan for a family of products. The opening inventory is 100 units, and an increase to 130 units is expected by the end of the plan. The demand for each month is given in what follows. Calculate the total production, daily production, and production and ending inventory for each month. opening inventory 100 ending inventory Month 130 May Jun Total production Daily leveled production Jul Aug Total 560 Total production required = Total forecast + back orders + ending inventory-opening inventory 8 Calculate by days, since different month has the different number of working days. Problem Set 01 Formulas Data Review View Tell me 11 A A A ac Wrap Text General Insert Delete Merge & Center % , .00 .0 00 0 Conditional Format Formatting as Table Cell Styles Format Excel File Edit View Insert Format Tools Data Window Help AutoSave OFF Home Insert Draw Page Layout G Paste Calibri (Body) BI U J54 A fx B C D E F G H WE ( > > Sat Sep 23 3:40 PM Sort & Find & Filter Select Comments Share Analyze Data Sensitivity J K L M N O P Q R S T U V W X Y Z 2.11. A company wants to develop a level production plan for a family of products. The opening inventory is 100 units, and an increase to 130 units is expected by the end of the plan. The demand for each month is given in what follows. Calculate the total production, daily production, and production and ending inventory for each month. 24 25 opening inventory 26 ending inventory 100 130 Total production Daily leveled production 27 Month May Jun Jul Aug Total 28 Working Days 21 19 20 29 Forecast Demand 115 125 140 30 Planned Production 168 152 160 10 150 80 70 530 Planned 31 Inventory 100 560 Total production required = Total forecast + back orders + ending inventory - opening inventory 8 Calculate by days, since different month has the different number of working days. Monthly production = daily produciton * number of working days Ending inventory a period = precious ending inventory + production-demand 32 34 3333 110,250 1470 Planned, or idealy 2.17. For the following data, calculate the number of workers required for level production and the resulting month- end inventories. Each worker can produce 15 units per day, and the desired ending inventory is 9000 units. 35 36 opening inventory 37 ending inventory 38 Month 39 Working Days 40 Forecast Demand 41 Planned Production 11,250 9,000 Total production Daily leveled production 1 2 3 4 Total 20 24 12 28,000 27,500 28,500 19 28,500 75 112,500 29400 Planned 42 Inventory 11,250 43 Per worker per day 44 Number of workers needed 45 Actual daily production 46 15 98 1470 Actual 2.18. For the following data, calculate the number of workers required for level production and the resulting month- end inventories. Each worker can produce 9 units per day, and the desired ending inventory is 800 units. Why is it not 47 possible to reach the exact ending inventory target? 48 opening inventory 49 ending inventory 50 Month 51 Working Days 52 Forecast Demand 53 Planned Production Planned 54 Inventory 55 Dor worker nor day 1,000 800 Total production 17,700 Daily leveled production 151.2821 Planned 1 2 3 4 5 6 Total 20 24 12 22 20 19 2,800 3,000 3060 3672 2,700 1836 3,300 3366 2,900 3060 3,200 2907 117 17,900 1,000 1,260 1,932 1,068 1,134 1,294 1,001 Chapter 2 Ready Accessibility: Investigate |B| + 100% Excel File Edit View Insert Format Tools Data Window Help ( Sat Sep 23 3:40 PM AutoSave OFF Problem Set 01 Home Insert Draw Page Layout Formulas Data Review View Tell me Calibri (Body) 11 Paste BI U V A A A ac Wrap Text General Insert Delete AIA Merge & Center % , .0 00 0 .00 WE > > Conditional Format Formatting as Table Cell Styles Format Sort & Find & Filter Select Comments Analyze Data Sensitivity Share J54 fx A B C D E F G H 33 J K L M N O P Q R S T U V W X Y Z A 34 2.17. For the following data, calculate the number of workers required for level production and the resulting month- end inventories. Each worker can produce 15 units per day, and the desired ending inventory is 9000 units. 35 36 opening inventory 37 ending inventory 38 Month 39 Working Days 40 Forecast Demand 41 Planned Production 42 Planned Inventory 43 Per worker per day 44 11,250 Number of workers needed 11,250 9,000 Total production Daily leveled production 1 2 3 4 Total 20 24 12 28,000 27,500 28,500 19 28,500 75 112,500 29400 15 98 110,250 1470 Planned, or idealy 45 Actual daily production 46 1470 Actual 2.18. For the following data, calculate the number of workers required for level production and the resulting month- end inventories. Each worker can produce 9 units per day, and the desired ending inventory is 800 units. Why is it not 47 possible to reach the exact ending inventory target? 48 opening inventory 17,700 49 ending inventory 50 Month 51 Working Days 52 Forecast Demand 53 Planned Production Planned 54 Inventory 55 Per worker per day 1,000 800 Total production Daily leveled production 151.2821 Planned 1 2 3 4 5 6 Total 20 24 12 22 20 19 2,800 3,000 2,700 3,300 3060 3672 1836 3366 2,900 3060 3,200 2907 117 17,900 1,000 1,260 1,932 1,068 1,134 1,294 1,001 9 56 Number of workers needed 17 57 Actual daily production 153 58 Why is it not possible to reach the exact ending inventory target? 59 60 61 62 63 64 65 66 67 68 Ready Chapter 2 Accessibility: Investigate |B| 10070

Step by Step Solution

There are 3 Steps involved in it

Step: 1

Lets break down each problem and solve them step by step Problem 26 Calculate the expected periodend inventory Given Opening Inventory OI 600 units Forecasted Demand D for each period Planned Producti...

See step-by-step solutions with expert insights and AI powered tools for academic success

Step: 2

Step: 3

Ace Your Homework with AI

Get the answers you need in no time with our AI-driven, step-by-step assistance

Get Started