Answered step by step

Verified Expert Solution

Question

1 Approved Answer

Hot&Cold is a European manufacturer of home appliances worldwide sales. The annual demand in each of the five regions (N. America, S. America, Europe,

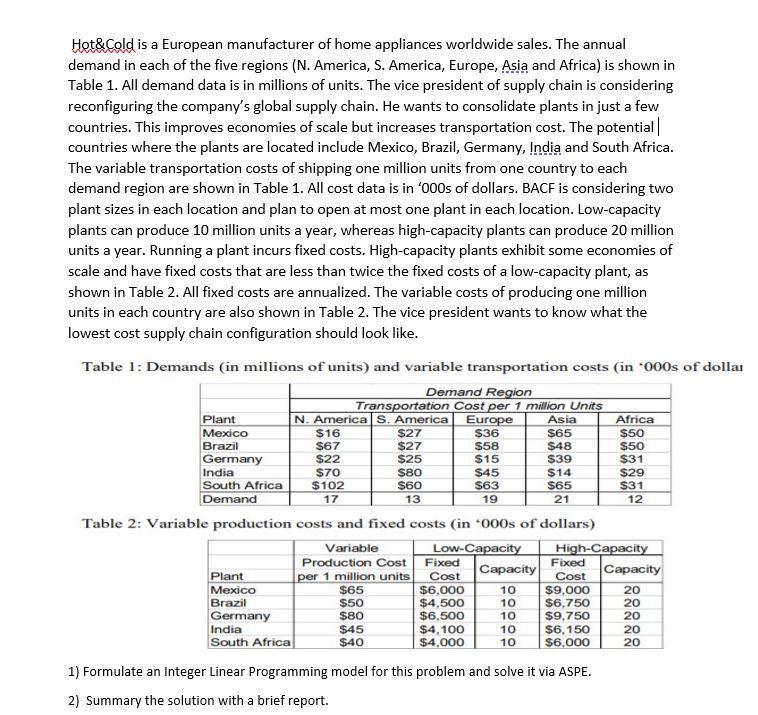

Hot&Cold is a European manufacturer of home appliances worldwide sales. The annual demand in each of the five regions (N. America, S. America, Europe, Asia and Africa) is shown in Table 1. All demand data is in millions of units. The vice president of supply chain is considering reconfiguring the company's global supply chain. He wants to consolidate plants in just a few countries. This improves economies of scale but increases transportation cost. The potential | countries where the plants are located include Mexico, Brazil, Germany, India and South Africa. The variable transportation costs of shipping one million units from one country to each demand region are shown in Table 1. All cost data is in '000s of dollars. BACF is considering two plant sizes in each location and plan to open at most one plant in each location. Low-capacity plants can produce 10 million units a year, whereas high-capacity plants can produce 20 million units a year. Running a plant incurs fixed costs. High-capacity plants exhibit some economies of scale and have fixed costs that are less than twice the fixed costs of a low-capacity plant, as shown in Table 2. All fixed costs are annualized. The variable costs of producing one million units in each country are also shown in Table 2. The vice president wants to know what the lowest cost supply chain configuration should look like. Table 1: Demands (in millions of units) and variable transportation costs (in '000s of dollar Demand Region Transportation Cost per 1 million Units Europe $36 $58 $15 Plant Mexico Brazil Germany India South Africa Demand N. America S. America $16 $27 $67 $27 $25 Plant Mexico Brazil Germany India South Africa $22 $70 $102 17 $80 $60 13 Fixed Cost $6,000 $4,500 $6,500 $45 $63 19 Table 2: Variable production costs and fixed costs (in '000s of dollars) Variable Low-Capacity Production Cost per 1 million units $65 $50 $80 $45 $40 $4,100 $4,000 Asia $65 $48 $39 $14 $65 21 Fixed Capacity Cost 10 $9,000 10 $6,750 10 $9,750 10 $6,150 $6,000 10 Africa $50 $50 High-Capacity 1) Formulate an Integer Linear Programming model for this problem and solve it via ASPE. 2) Summary the solution with a brief report. $31 $29 $31 12 Capacity 20 20 20 20 20

Step by Step Solution

★★★★★

3.55 Rating (152 Votes )

There are 3 Steps involved in it

Step: 1

Get Instant Access to Expert-Tailored Solutions

See step-by-step solutions with expert insights and AI powered tools for academic success

Step: 2

Step: 3

Ace Your Homework with AI

Get the answers you need in no time with our AI-driven, step-by-step assistance

Get Started