Answered step by step

Verified Expert Solution

Question

1 Approved Answer

I need help with questions 4,5, & 6. what information do you need? i have questions 1,2,3 & 4 done. Do you need the answerss

I need help with questions 4,5, & 6.

what information do you need? i have questions 1,2,3 & 4 done. Do you need the answerss to previous question?

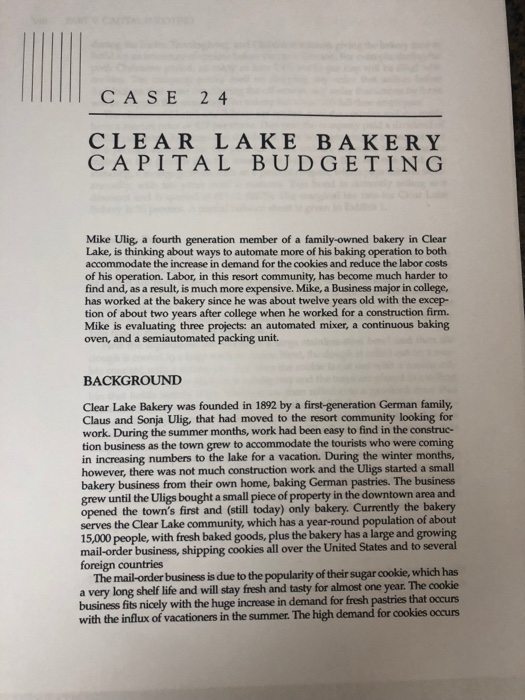

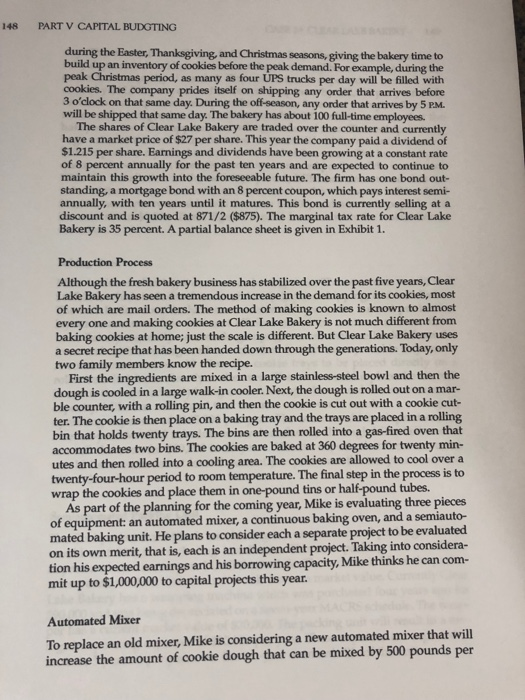

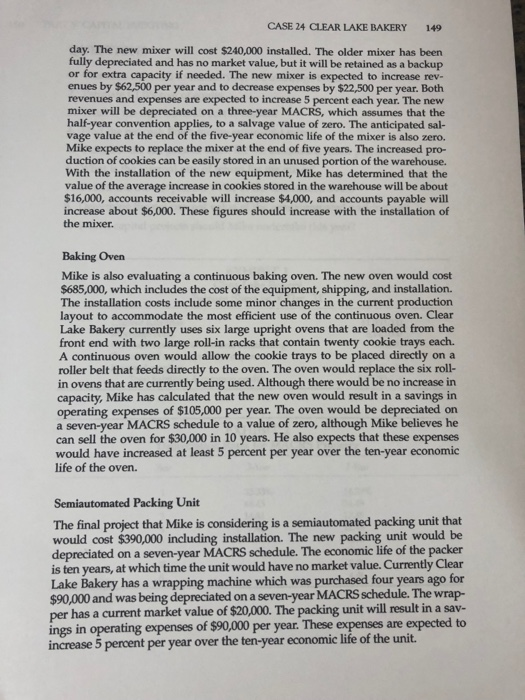

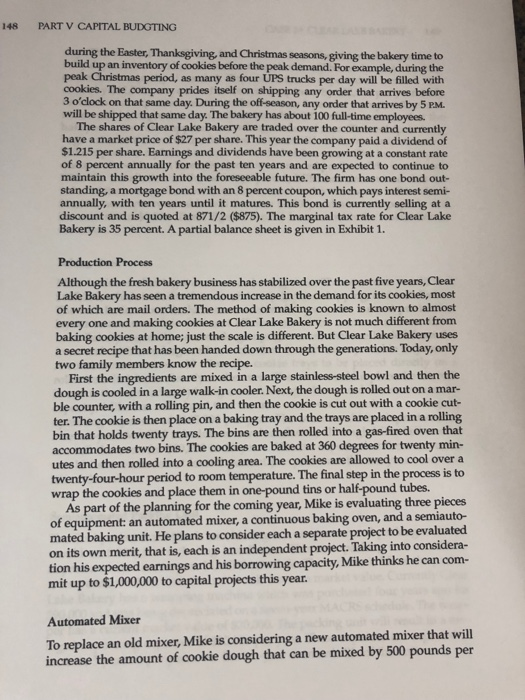

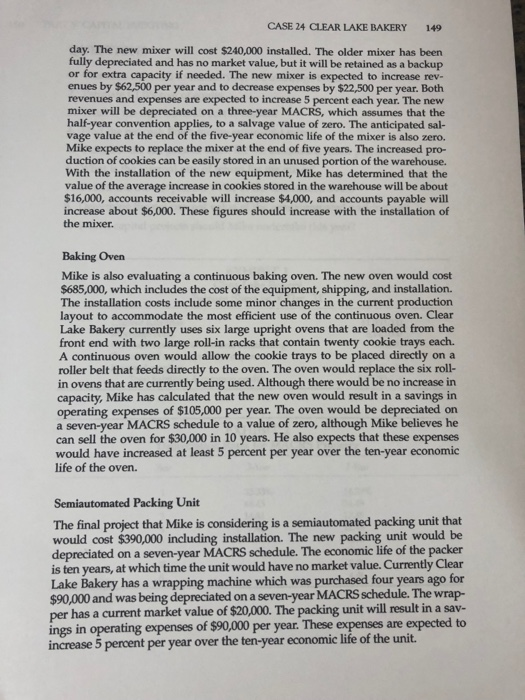

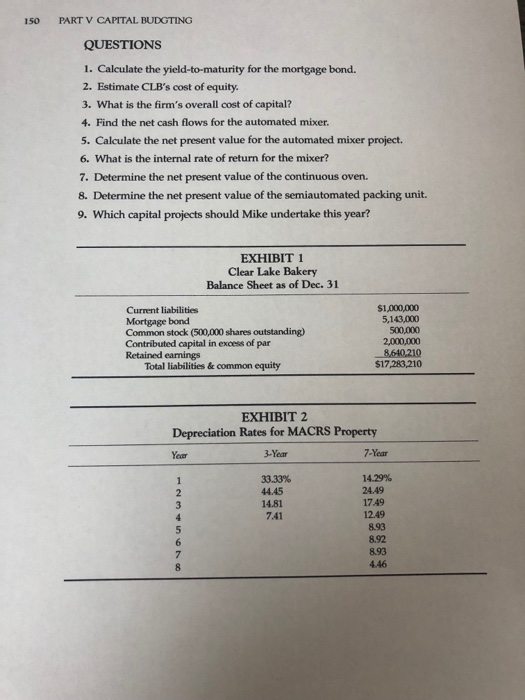

CASE 24 CLEAR LAKE BAKERY CAPITAL BUDGETING Mike Ulig, a fourth generation member of a family-owned bakery in Clear Lake, is thinking about ways to automate more of his baking operation to both accommodate the increase in demand for the cookies and reduce the labor costs of his operation. Labor, in this resort community, has become much harder to find and, as a result, is much more expensive. Mike, a Business major in college, has worked at the bakery since he was about twelve years old with the excep- tion of about two years after college when he worked for a construction firm. Mike is evaluating three projects: an automated mixer, a continuous baking oven, and a semiautomated packing unit. BACKGROUND Clear Lake Bakery was founded in 1892 by a first-generation German family, Claus and Sonja Ulig, that had moved to the resort community looking for work. During the summer months, work had been easy to find in the construc- tion business as the town grew to accommodate the tourists who were coming in increasing numbers to the lake for a vacation. During the winter months, however, there was not much construction work and the Uligs started a small bakery business from their own home, baking German pastries. The business grew until the Uligs bought a small piece of property in the downtown area and opened the town's first and (still today) only bakery. Currently the bakery serves the Clear Lake community, which has a year-round population of about 15,000 people, with fresh baked goods, plus the bakery has a large and growing mail-order business, shipping cookies all over the United States and to several foreign countries The mail-order business is due to the popularity of their sugar cookie, which has a very long shelf life and will stay fresh and tasty for almost one year. The cookie business fits nicely with the huge increase in demand for fresh pastries that occurs with the influx of vacationers in the summer. The high demand for cookies occurs 148 PART V CAPITAL BUDGTING during the Easter, Thanksgiving and Christmas seasons, giving the bakery time to build up an inventory of cookies before the peak demand. For example, during the peak Christmas period, as many as four UPS trucks per day will be filled with cookies. The company prides itself on shipping any order that arrives before 3 o'clock on that same day. During the off-season, any order that arrives by 5 P.M. will be shipped that same day. The bakery has about 100 full-time employees. The shares of Clear Lake Bakery are traded over the counter and currently have a market price of $27 per share. This year the company paid a dividend of $1.215 per share. Earnings and dividends have been growing at a constant rate of 8 percent annually for the past ten years and are expected to continue to maintain this growth into the foreseeable future. The firm has one bond out- standing, a mortgage bond with an 8 percent coupon, which pays interest semi- annually, with ten years until it matures. This bond is currently selling at a discount and is quoted at 871/2 ($875). The marginal tax rate for Clear Lake Bakery is 35 percent. A partial balance sheet is given in Exhibit 1. Production Process Although the fresh bakery business has stabilized over the past five years, Clear Lake Bakery has seen a tremendous increase in the demand for its cookies, most of which are mail orders. The method of making cookies is known to almost every one and making cookies at Clear Lake Bakery is not much different from baking cookies at home; just the scale is different. But Clear Lake Bakery uses a secret recipe that has been handed down through the generations. Today, only two family members know the recipe. First the ingredients are mixed in a large stainless-steel bowl and then the dough is cooled in a large walk-in cooler. Next, the dough is rolled out on a mar- ble counter, with a rolling pin, and then the cookie is cut out with a cookie cut- ter. The cookie is then place on a baking tray and the trays are placed in a rolling bin that holds twenty trays. The bins are then rolled into a gas-fired oven that accommodates two bins. The cookies are baked at 360 degrees for twenty min- utes and then rolled into a cooling area. The cookies are allowed to cool over a twenty-four-hour period to room temperature. The final step in the process is to wrap the cookies and place them in one-pound tins or half-pound tubes. As part of the planning for the coming year, Mike is evaluating three pieces of equipment: an automated mixer, a continuous baking oven, and a semiauto- mated baking unit. He plans to consider each a separate project to be evaluated on its own merit, that is, each is an independent project. Taking into considera- tion his expected earnings and his borrowing capacity, Mike thinks he can com- mit up to $1,000,000 to capital projects this year. Automated Mixer To replace an old mixer, Mike is considering a new automated mixer that will increase the amount of cookie dough that can be mixed by 500 pounds per CASE 24 CLEAR LAKE BAKERY 149 day. The new mixer will cost $240,000 installed. The older mixer has been fully depreciated and has no market value, but it will be retained as a backup or for extra capacity if needed. The new mixer is expected to increase rev- enues by $62,500 per year and to decrease expenses by $22,500 per year. Both revenues and expenses are expected to increase 5 percent each year. The new mixer will be depreciated on a three-year MACRS, which assumes that the half-year convention applies, to a salvage value of zero. The anticipated sal- vage value at the end of the five-year economic life of the mixer is also zero. Mike expects to replace the mixer at the end of five years. The increased pro- duction of cookies can be easily stored in an unused portion of the warehouse. With the installation of the new equipment, Mike has determined that the value of the average increase in cookies stored in the warehouse will be about $16,000, accounts receivable will increase $4,000, and accounts payable will increase about $6,000. These figures should increase with the installation of the mixer. Baking Oven Mike is also evaluating a continuous baking oven. The new oven would cost $685,000, which includes the cost of the equipment, shipping, and installation. The installation costs include some minor changes in the current production layout to accommodate the most efficient use of the continuous oven. Clear Lake Bakery currently uses six large upright ovens that are loaded from the front end with two large roll-in racks that contain twenty cookie trays each. A continuous oven would allow the cookie trays to be placed directly on a roller belt that feeds directly to the oven. The oven would replace the six roll- in ovens that are currently being used. Although there would be no increase in capacity, Mike has calculated that the new oven would result in a savings in operating expenses of $105,000 per year. The oven would be depreciated on a seven-year MACRS schedule to a value of zero, although Mike believes he can sell the oven for $30,000 in 10 years. He also expects that these expenses would have increased at least 5 percent per year over the ten-year economic life of the oven. Semiautomated Packing Unit The final project that Mike is considering is a semiautomated packing unit that would cost $390,000 including installation. The new packing unit would be depreciated on a seven-year MACRS schedule. The economic life of the packer is ten years, at which time the unit would have no market value. Currently Clear Lake Bakery has a wrapping machine which was purchased four years ago for $90,000 and was being depreciated on a seven-year MACRS schedule. The wrap- per has a current market value of $20,000. The packing unit will result in a sav- ings in operating expenses of $90,000 per year. These expenses are expected to increase 5 percent per year over the ten-year economic life of the unit. 150 PART V CAPITAL BUDGTING QUESTIONS 1. Calculate the yield-to-maturity for the mortgage bond. 2. Estimate CLB's cost of equity. 3. What is the firm's overall cost of capital? 4. Find the net cash flows for the automated mixer. 5. Calculate the net present value for the automated mixer project. 6. What is the internal rate of return for the mixer? 7. Determine the net present value of the continuous oven. 8. Determine the net present value of the semiautomated packing unit 9. Which capital projects should Mike undertake this year? EXHIBIT 1 Clear Lake Bakery Balance Sheet as of Dec. 31 Current liabilities Mortgage bond Common stock (500,000 shares outstanding) Contributed capital in excess of par Retained eamings Total liabilities & common equity $1,000,000 5,143,000 500,000 2,000,000 8.610.210 $17283.210 EXHIBIT 2 Depreciation Rates for MACRS Property Your 3-Year 7-Year 33.33% 44.45 14.81 7.41 14.29% 24.49 17.49 12.49 8.93 892 8.93 4.46 CASE 24 CLEAR LAKE BAKERY CAPITAL BUDGETING Mike Ulig, a fourth generation member of a family-owned bakery in Clear Lake, is thinking about ways to automate more of his baking operation to both accommodate the increase in demand for the cookies and reduce the labor costs of his operation. Labor, in this resort community, has become much harder to find and, as a result, is much more expensive. Mike, a Business major in college, has worked at the bakery since he was about twelve years old with the excep- tion of about two years after college when he worked for a construction firm. Mike is evaluating three projects: an automated mixer, a continuous baking oven, and a semiautomated packing unit. BACKGROUND Clear Lake Bakery was founded in 1892 by a first-generation German family, Claus and Sonja Ulig, that had moved to the resort community looking for work. During the summer months, work had been easy to find in the construc- tion business as the town grew to accommodate the tourists who were coming in increasing numbers to the lake for a vacation. During the winter months, however, there was not much construction work and the Uligs started a small bakery business from their own home, baking German pastries. The business grew until the Uligs bought a small piece of property in the downtown area and opened the town's first and (still today) only bakery. Currently the bakery serves the Clear Lake community, which has a year-round population of about 15,000 people, with fresh baked goods, plus the bakery has a large and growing mail-order business, shipping cookies all over the United States and to several foreign countries The mail-order business is due to the popularity of their sugar cookie, which has a very long shelf life and will stay fresh and tasty for almost one year. The cookie business fits nicely with the huge increase in demand for fresh pastries that occurs with the influx of vacationers in the summer. The high demand for cookies occurs 148 PART V CAPITAL BUDGTING during the Easter, Thanksgiving and Christmas seasons, giving the bakery time to build up an inventory of cookies before the peak demand. For example, during the peak Christmas period, as many as four UPS trucks per day will be filled with cookies. The company prides itself on shipping any order that arrives before 3 o'clock on that same day. During the off-season, any order that arrives by 5 P.M. will be shipped that same day. The bakery has about 100 full-time employees. The shares of Clear Lake Bakery are traded over the counter and currently have a market price of $27 per share. This year the company paid a dividend of $1.215 per share. Earnings and dividends have been growing at a constant rate of 8 percent annually for the past ten years and are expected to continue to maintain this growth into the foreseeable future. The firm has one bond out- standing, a mortgage bond with an 8 percent coupon, which pays interest semi- annually, with ten years until it matures. This bond is currently selling at a discount and is quoted at 871/2 ($875). The marginal tax rate for Clear Lake Bakery is 35 percent. A partial balance sheet is given in Exhibit 1. Production Process Although the fresh bakery business has stabilized over the past five years, Clear Lake Bakery has seen a tremendous increase in the demand for its cookies, most of which are mail orders. The method of making cookies is known to almost every one and making cookies at Clear Lake Bakery is not much different from baking cookies at home; just the scale is different. But Clear Lake Bakery uses a secret recipe that has been handed down through the generations. Today, only two family members know the recipe. First the ingredients are mixed in a large stainless-steel bowl and then the dough is cooled in a large walk-in cooler. Next, the dough is rolled out on a mar- ble counter, with a rolling pin, and then the cookie is cut out with a cookie cut- ter. The cookie is then place on a baking tray and the trays are placed in a rolling bin that holds twenty trays. The bins are then rolled into a gas-fired oven that accommodates two bins. The cookies are baked at 360 degrees for twenty min- utes and then rolled into a cooling area. The cookies are allowed to cool over a twenty-four-hour period to room temperature. The final step in the process is to wrap the cookies and place them in one-pound tins or half-pound tubes. As part of the planning for the coming year, Mike is evaluating three pieces of equipment: an automated mixer, a continuous baking oven, and a semiauto- mated baking unit. He plans to consider each a separate project to be evaluated on its own merit, that is, each is an independent project. Taking into considera- tion his expected earnings and his borrowing capacity, Mike thinks he can com- mit up to $1,000,000 to capital projects this year. Automated Mixer To replace an old mixer, Mike is considering a new automated mixer that will increase the amount of cookie dough that can be mixed by 500 pounds per CASE 24 CLEAR LAKE BAKERY 149 day. The new mixer will cost $240,000 installed. The older mixer has been fully depreciated and has no market value, but it will be retained as a backup or for extra capacity if needed. The new mixer is expected to increase rev- enues by $62,500 per year and to decrease expenses by $22,500 per year. Both revenues and expenses are expected to increase 5 percent each year. The new mixer will be depreciated on a three-year MACRS, which assumes that the half-year convention applies, to a salvage value of zero. The anticipated sal- vage value at the end of the five-year economic life of the mixer is also zero. Mike expects to replace the mixer at the end of five years. The increased pro- duction of cookies can be easily stored in an unused portion of the warehouse. With the installation of the new equipment, Mike has determined that the value of the average increase in cookies stored in the warehouse will be about $16,000, accounts receivable will increase $4,000, and accounts payable will increase about $6,000. These figures should increase with the installation of the mixer. Baking Oven Mike is also evaluating a continuous baking oven. The new oven would cost $685,000, which includes the cost of the equipment, shipping, and installation. The installation costs include some minor changes in the current production layout to accommodate the most efficient use of the continuous oven. Clear Lake Bakery currently uses six large upright ovens that are loaded from the front end with two large roll-in racks that contain twenty cookie trays each. A continuous oven would allow the cookie trays to be placed directly on a roller belt that feeds directly to the oven. The oven would replace the six roll- in ovens that are currently being used. Although there would be no increase in capacity, Mike has calculated that the new oven would result in a savings in operating expenses of $105,000 per year. The oven would be depreciated on a seven-year MACRS schedule to a value of zero, although Mike believes he can sell the oven for $30,000 in 10 years. He also expects that these expenses would have increased at least 5 percent per year over the ten-year economic life of the oven. Semiautomated Packing Unit The final project that Mike is considering is a semiautomated packing unit that would cost $390,000 including installation. The new packing unit would be depreciated on a seven-year MACRS schedule. The economic life of the packer is ten years, at which time the unit would have no market value. Currently Clear Lake Bakery has a wrapping machine which was purchased four years ago for $90,000 and was being depreciated on a seven-year MACRS schedule. The wrap- per has a current market value of $20,000. The packing unit will result in a sav- ings in operating expenses of $90,000 per year. These expenses are expected to increase 5 percent per year over the ten-year economic life of the unit. 150 PART V CAPITAL BUDGTING QUESTIONS 1. Calculate the yield-to-maturity for the mortgage bond. 2. Estimate CLB's cost of equity. 3. What is the firm's overall cost of capital? 4. Find the net cash flows for the automated mixer. 5. Calculate the net present value for the automated mixer project. 6. What is the internal rate of return for the mixer? 7. Determine the net present value of the continuous oven. 8. Determine the net present value of the semiautomated packing unit 9. Which capital projects should Mike undertake this year? EXHIBIT 1 Clear Lake Bakery Balance Sheet as of Dec. 31 Current liabilities Mortgage bond Common stock (500,000 shares outstanding) Contributed capital in excess of par Retained eamings Total liabilities & common equity $1,000,000 5,143,000 500,000 2,000,000 8.610.210 $17283.210 EXHIBIT 2 Depreciation Rates for MACRS Property Your 3-Year 7-Year 33.33% 44.45 14.81 7.41 14.29% 24.49 17.49 12.49 8.93 892 8.93 4.46 Step by Step Solution

There are 3 Steps involved in it

Step: 1

Get Instant Access to Expert-Tailored Solutions

See step-by-step solutions with expert insights and AI powered tools for academic success

Step: 2

Step: 3

Ace Your Homework with AI

Get the answers you need in no time with our AI-driven, step-by-step assistance

Get Started