Question

I need questions answered from Chapter 14 (Lean Supply Chains), specifically Case: QualityParts Company (LO14-2). GREEN TRIANGE AND RED ARROW *****( The green triangle is

I need questions answered from Chapter 14 (Lean Supply Chains), specifically Case: QualityParts Company (LO14-2).

GREEN TRIANGE AND RED ARROW

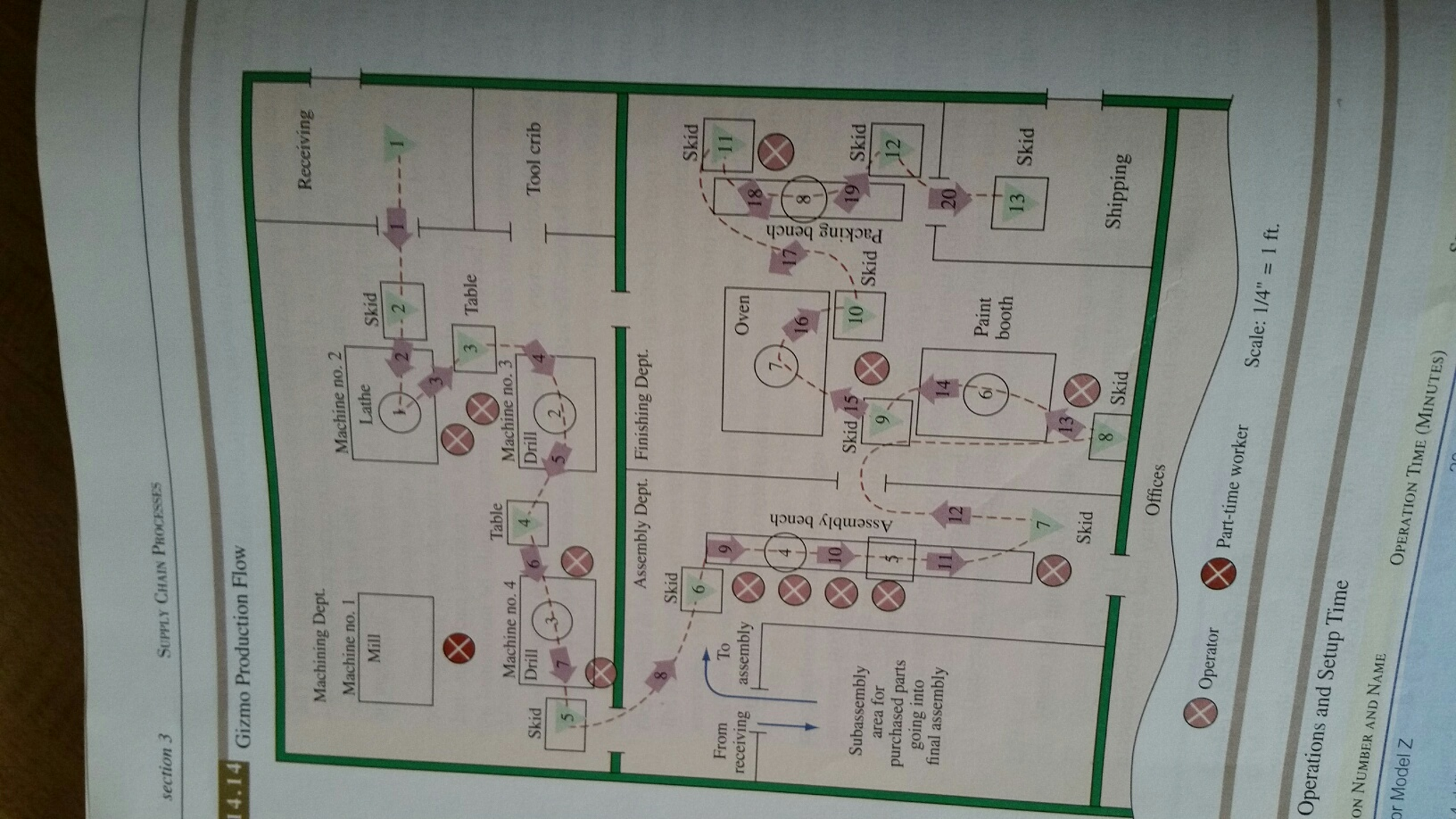

*****(The green triangle is a temporary stopping point in the process. The red arrow is a separate step in the process flow.)

Question 2. Make recommendations for lean improvements in such areas as scheduling, layout, kanban, task groupings, and inventory. Use quantitative data as much as possible; state necessary assumptions.

Operations and Supply Chain Management ISBN 978-0-07-802402-3 Pages 369-371

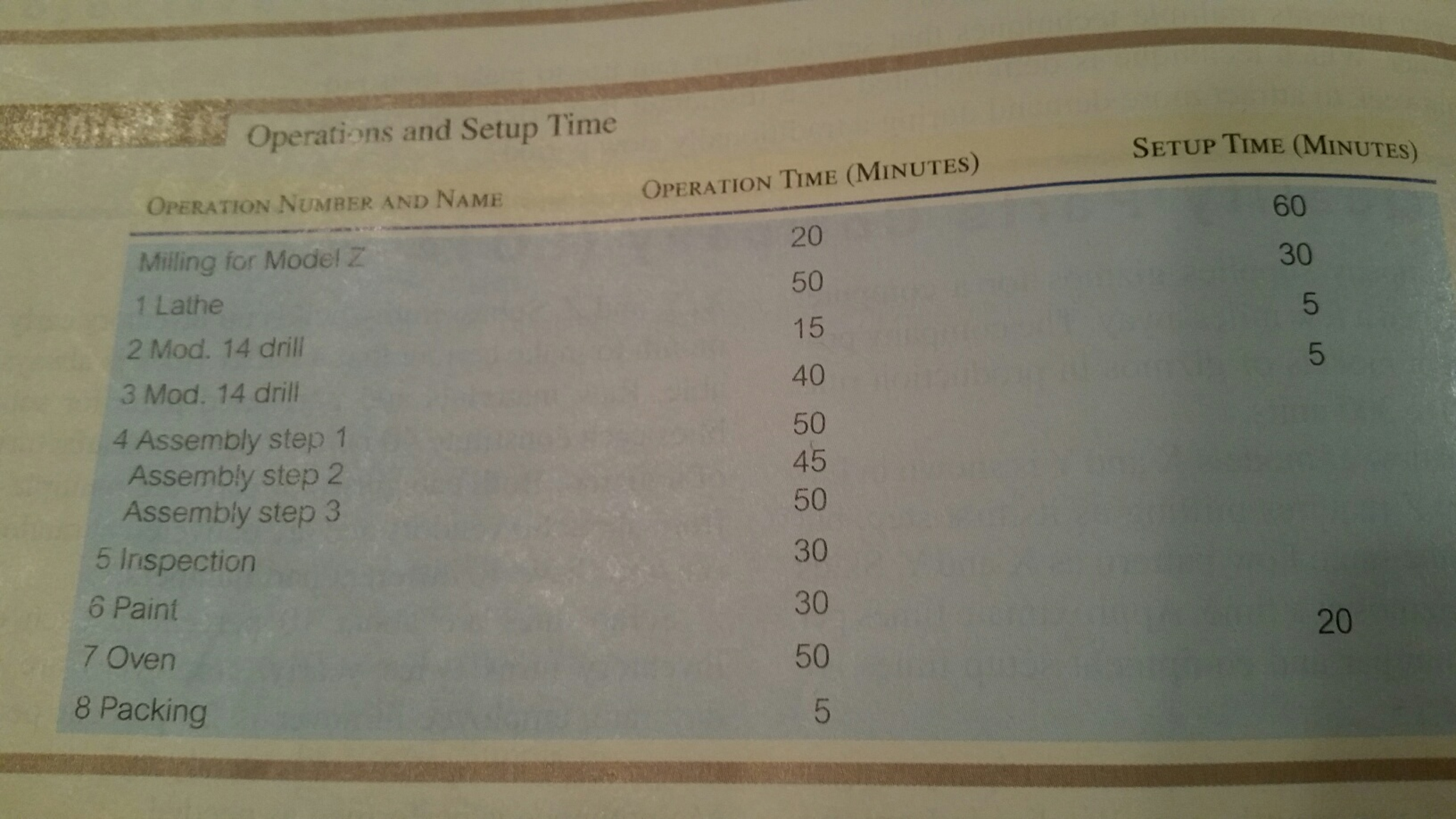

Case: Quality Parts Company (LO14-2) Exhibits 14.14 and 14.15 attached separately

Quality Parts Company supplies gizmos for a computer manufacturer located a few miles away. The company produces two different models of gizmos in production runs ranging from 100 to 300 units. The production flow 0f models X and Y is shown in Exhibit 14.14. Model Z requires milling as its first step, but otherwise follows the same flow pattern as X and Y. Skids can hold up to 20 gizmos at a time. Approximate times per unit by operation number and equipment setup times are shown in exhibit 14.15.

Demand for gizmos from the computer company ranges between 125 and 175 per month, equally divided among X, Y, and Z. Subassembly builds up inventory early in the month to make certain that a buffer stock is always available. Raw materials and purchased parts for subassemblies each constitute 40 percent of the manufacturing costs of a gizmo. Both categories of parts are multiple- sourced from about 80 vendors and are delivered at random times. (Gizmos have 40 different part numbers.)

Scrap rates are about 10 percent at each operation, inventory turns twice yearly, employees are paid on a day rate, employee turnover is 25 percent per year, and net profit from operations is steady at 5 percent per year. Maintenance is performed as needed.

The manager of Quality Parts Company has been contemplating installing an automated ordering system to help control inventories and to keep skids filled. (She feels that two days of work in front of a workstation motivates the worker to produce at top speed.) She is also planning to add three inspectors to clean up the quality problem. Further, she is thinking about setting up a rework line to speed repairs. Although she is pleased with the high utilization of most of her equipment and labor, she is concerned about the idle time of the milling machine. Finally she has asked the industrial engineering department to look into high-rise shelving to store parts coming off machine 4.

________________________________________________________

Exhibit 14.15 perations and Setup Times

________________________________________________________________

Exhibit 14.14 - Below

Step by Step Solution

There are 3 Steps involved in it

Step: 1

Get Instant Access to Expert-Tailored Solutions

See step-by-step solutions with expert insights and AI powered tools for academic success

Step: 2

Step: 3

Ace Your Homework with AI

Get the answers you need in no time with our AI-driven, step-by-step assistance

Get Started