Question

I want help ONLY with the selection of electro motor,what is the suitable motor for this design and why? The electro motors can be selected

I want help ONLY with the selection of electro motor,what is the suitable motor for this design and why?

The electro motors can be selected from Bosch and Mavilor Catalogues

http://www.boschmotorsandcontrols.co.uk/elektromotoren/gleichstrommotoren/ohne-getriebe/index.htm#

https://acdcdrives.co.uk/

- Introduction

Forging is a forming process that involves applying compressive forces to a work piece to deform it, and create a desired geometric change to the material. The vast variety of components that can be produced can be seen in Figure 1. Forging can strengthen the material by sealing cracks and closing empty spaces within the material. The geometry of a component is formed by squeezing the material into dies. Die forgings generally have about a 20% higher strength-to-weight ratio when compared to machined or cast parts of the same material. The force and continued pressure required in this process is generated via a powered press.

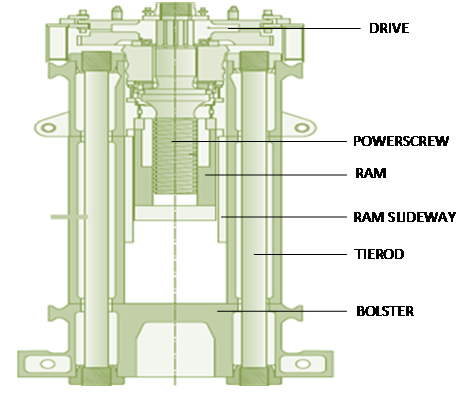

The constructional features of a power press (cf. Figure 2) are almost similar to that of the hand/ fly press, the only difference being, the ram, instead of driven by hand, is driven by power from a motor. The factor which should be considered while selecting a press for a given job are: the overall work size, the stock thickness and material, kind of operation to be performed, power required and speed of operation. A press is rated in tonnes or Newtons of force that can be applied to the ram without undue strain and without affecting the structural strength of the press. A powered screw press such as that in Figure 2, is a type of machine press in which the ram is driven up and down by a screw.

- Design brief

For this task, you are required to design a screw power press. Employing the application of power screw(s), shaft(s), gears and their respective control systems. The machine power screw must be run using an electromotor and gearbox which should be designed as a part of this course work.

Applying sound engineering principles, you are required to propose an effective means of applying torque from an electromotor to the moving power screw and produce the required force. Power screws are used for providing linear motion in a smooth uniform manner. They are linear actuators that transform rotary into linear motion.

- Technical specifications for the system:

- Maximum working envelope defined in Figure 3.

- Reliability - 95%.

- Factor of safety to be agreed with client

- Life - 10 years, assume 15 hours per day, 5 days per week.

- Maximum operating temperature: 32 C.

- Minimum operating temperature: -5 C.

- The power screw used for this application must be self-locking.

- The Gearbox can accommodate any type of Bevel, Spur or Helical gears but not Worm gears.

- Initially 15 to be designed and manufactured for the European market.

- The system must be user friendly.

- Continuously permitted press - 40,000 N

- Die-to-die blow force - 55,000 N

- Stroke rate max- 10/ min

- Distance bed slide max. 1,200mm

- Usable Bolster width - 1,600mm

- Usable Bolster depth - 1,200mm

- System must adhere to UK safety standards.

- Corrosion resistance may be considered through the use of specialised materials or surface protection methods.

- The system must be considered a sustainable design.

- The selection of materials and their use within the product must be in accordance to European Standards.

- Design must comply to - BS EN ISO 225:2010 (where appropriate).

- The system must operate with a single point control.

Step by Step Solution

There are 3 Steps involved in it

Step: 1

Get Instant Access to Expert-Tailored Solutions

See step-by-step solutions with expert insights and AI powered tools for academic success

Step: 2

Step: 3

Ace Your Homework with AI

Get the answers you need in no time with our AI-driven, step-by-step assistance

Get Started