in organized way please

in organized way please

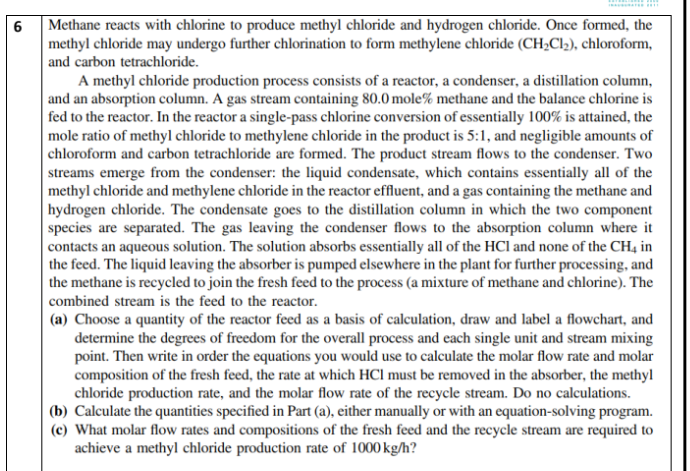

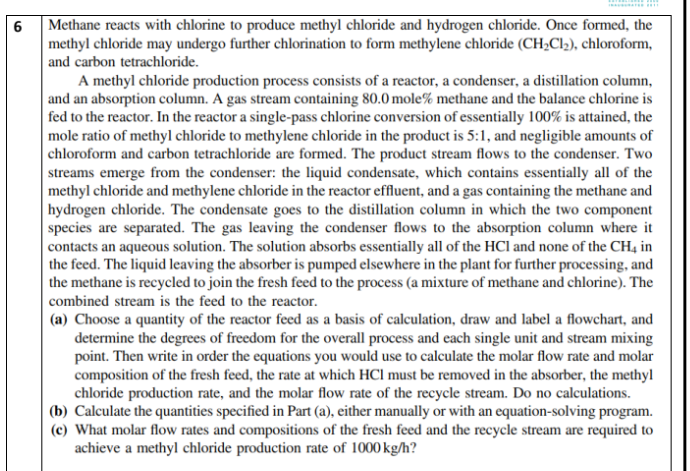

Methane reacts with chlorine to produce methyl chloride and hydrogen chloride. Once formed, the methyl chloride may undergo further chlorination to form methylene chloride (CH2Cl2), chloroform, and carbon tetrachloride. A methyl chloride production process consists of a reactor, a condenser, a distillation column, and an absorption column. A gas stream containing 80.0 mole\% methane and the balance chlorine is fed to the reactor. In the reactor a single-pass chlorine conversion of essentially 100% is attained, the mole ratio of methyl chloride to methylene chloride in the product is 5:1, and negligible amounts of chloroform and carbon tetrachloride are formed. The product stream flows to the condenser. Two streams emerge from the condenser: the liquid condensate, which contains essentially all of the methyl chloride and methylene chloride in the reactor effluent, and a gas containing the methane and hydrogen chloride. The condensate goes to the distillation column in which the two component species are separated. The gas leaving the condenser flows to the absorption column where it contacts an aqueous solution. The solution absorbs essentially all of the HCl and none of the CH4 in the feed. The liquid leaving the absorber is pumped elsewhere in the plant for further processing, and the methane is recycled to join the fresh feed to the process (a mixture of methane and chlorine). The combined stream is the feed to the reactor. (a) Choose a quantity of the reactor feed as a basis of calculation, draw and label a flowchart, and determine the degrees of freedom for the overall process and each single unit and stream mixing point. Then write in order the equations you would use to calculate the molar flow rate and molar composition of the fresh feed, the rate at which HCl must be removed in the absorber, the methyl chloride production rate, and the molar flow rate of the recycle stream. Do no calculations. (b) Calculate the quantities specified in Part (a), either manually or with an equation-solving program. (c) What molar flow rates and compositions of the fresh feed and the recycle stream are required to achieve a methyl chloride production rate of 1000kg/h

in organized way please

in organized way please