Answered step by step

Verified Expert Solution

Question

1 Approved Answer

In this supply chain game, retailers sell electronic pocket calen- dars to their customers and place replenishment orders to their wholesaler. The wholesaler sells

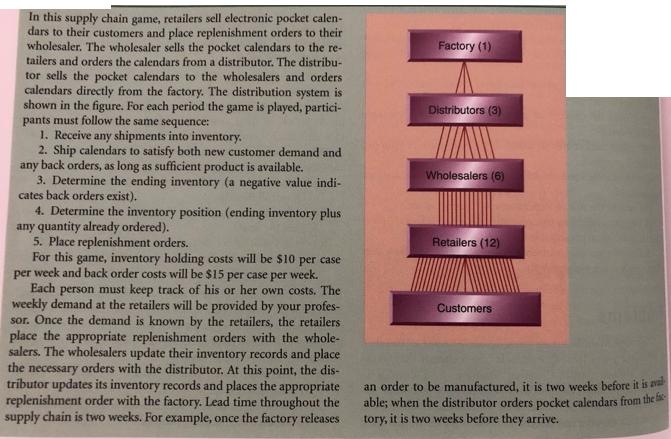

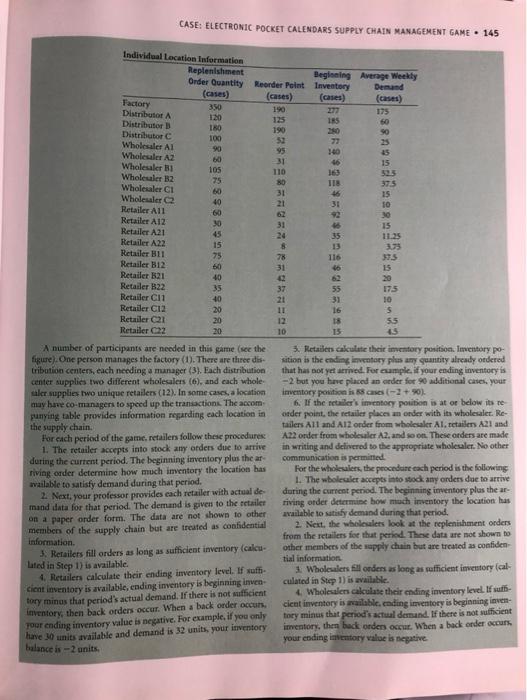

In this supply chain game, retailers sell electronic pocket calen- dars to their customers and place replenishment orders to their wholesaler. The wholesaler sells the pocket calendars to the re- tailers and orders the calendars from a distributor. The distribu- tor sells the pocket calendars to the wholesalers and orders calendars directly from the factory. The distribution system is shown in the figure. For each period the game is played, partici- pants must follow the same sequence: 1. Receive any shipments into inventory. 2. Ship calendars to satisfy both new customer demand and any back orders, as long as sufficient product is available. 3. Determine the ending inventory (a negative value indi- cates back orders exist). 4. Determine the inventory position (ending inventory plus any quantity already ordered). 5. Place replenishment orders. For this game, inventory holding costs will be $10 per case per week and back order costs will be $15 per case per week. Each person must keep track of his or her own costs. The weekly demand at the retailers will be provided by your profes- sor. Once the demand is known by the retailers, the retailers place the appropriate replenishment orders with the whole- salers. The wholesalers update their inventory records and place the necessary orders with the distributor. At this point, the dis- tributor updates its inventory records and places the appropriate replenishment order with the factory. Lead time throughout the supply chain is two weeks. For example, once the factory releases Factory (1) Distributors (3) Wholesalers (6) Retailers (12) Customers an order to be manufactured, it is two weeks before it is avail able; when the distributor orders pocket calendars from the f tory, it is two weeks before they arrive. Individual Location Information Replenishment CASE: ELECTRONIC POCKET CALENDARS SUPPLY CHAIN MANAGEMENT GAME 145 Factory Distributor A Distributor B Distributor C Wholesaler Al Wholesaler A2 Wholesaler BI Wholesaler B2 Wholesaler C1 Wholesaler C2 Retailer A11 Retailer A12 Retailer A21 Retailer A22 Retailer B11 Retailer B12 Retailer 821 Retailer B22 Retailer C11 Retailer C12 Retailer C21 Retailer C22 Order Quantity Reorder Point Inventory (cases) (cases) 350 120 180 100 90 60 105 75 60 40 60 BR928929288 30 45 15 75 60 40 35 40 20 20 20 (cases) 190 125 A number of participants are needed in this game (see the figure). One person manages the factory (1). There are three dis- tribution centers, each needing a manager (3). Each distribution center supplies two different wholesalers (6), and each whole- saler supplies two unique retailers (12). In some cases, a location may have co-managers to speed up the transactions. The accom punying table provides information regarding each location in the supply chain. For each period of the game, retailers follow these procedures 1. The retailer accepts into stock any orders due to arrive during the current period. The beginning inventory plus the ar- riving order determine how much inventory the location has available to satisfy demand during that period. 2. Next, your professor provides each retailer with actual de mand data for that period. The demand is given to the retailer on a paper order form. The data are not shown to other members of the supply chain but are treated as confidential information. 3. Retailers fill orders as long as sufficient inventory (calcu- lated in Step 1) is available. 4. Retailers calculate their ending inventory level. If suffi- cient inventory is available, ending inventory is beginning inven tory minus that period's actual demand. If there is not sufficient inventory, then back orders occur. When a back order occurs, your ending inventory value is negative. For example, if you only have 30 units available and demand is 32 units, your inventory balance is -2 units. 190 0026 95 31 110 80 31 24 8 78 31 42 37 12 Beginning Average Weekly 10 63862*22******** 277 185 77 140 46 118 46 31 92 46 35 13 116 46 55 31 16 18 15 Demand (cases) 175 ssnande2222-22 60 50 25 45 15 37.5 15 10 30 15 11.25 3.75 37.5 15 20 175 10 5.5 45 5. Retailers calculate their inventory position. Inventory po- sition is the ending inventory plus any quantity already ordered that has not yet arrived. For example, if your ending inventory is -2 but you have placed an order for 90 additional cases, your inventory position is 88 cases (-2+90). 6. If the retailer's inventory position is at or below its re- order point, the retailer places an order with its wholesaler. Re- tailers All and A12 order from wholesaler A1, retailers A21 and A22 order from wholesaler A2, and so on. These orders are made in writing and delivered to the appropriate wholesaler. No other communication is permitted. For the wholesalers, the procedure each period is the following 1. The wholesaler accepts into stock any orders due to arrive during the current period. The beginning inventory plus the ar- riving order determine how much inventory the location has available to satisfy demand during that period. 2. Next, the wholesalers look at the replenishment orders from the retailers for that period. These data are not shown to other members of the supply chain but are treated as confiden tial information 3. Wholesalers fill orders as long as sufficient inventory (cal- culated in Step 1) is available. 4. Wholesalers calculate their ending inventory level. If suffi- cient inventory is available. ending inventory is beginning inven tory minus that period's actual demand. If there is not sufficient inventory, then back orders occur. When a back order occurs, your ending inventory value is negative. 146 CHAPTER 4 SUPPLY CHAIN MANAGEMENT 5. Wholesalers calculate their inventory position. Inventory position is the ending inventory plus any quantity already or- dered that has not yet arrived. 6. If the wholesaler's inventory position is at or below its reorder point, the wholesaler places an order with its distributor. Wholesalers Al and A2 order from distributor A, wholesalers B1 and B2 order from distributor B, and so on. These orders are in writing and delivered to the appropriate distributor. No other communication is permitted. For the distributors, the procedure followed each period is the following: 1. The distributor accepts into stock any orders due to arrive during the current period. The beginning inventory plus the ar- riving order determine how much inventory the location has available to satisfy demand during that period. 2. Next, the distributor looks at the replenishment orders from its wholesalers for that period. These data are not shown to other members of the supply chain but are treated as confiden- tial information. 3. Distributors fill orders as long as sufficient inventory (cal- culated in Step 1) is available. 4. Distributors calculate their ending inventory level. If suf- ficient inventory is available, ending inventory is beginning in- ventory minus that period's actual demand. If there is not sufficient inventory then back orders occur. 5. Distributors calculate their inventory position. Inventory position is the ending inventory plus any quantity already or dered that has not yet arrived. 6. If the distributor's inventory position is at or below its re- order point, the distributor places an order with the factory. These orders are in writing and delivered to the appropriate dis- tributor. No other communication is permitted. The factory follows these procedures each period: I. The factory accepts into stock any manufacturing orders completed for the current period. The beginning inventory plus the arriving order determine how much inventory the location. has available to satisfy demand during that period. 2. Next, the factory looks at the replenishment orders from the distributors for that period. 3. The factory fills orders as long as sufficient inventory (cal. culated in Step 1) is available. 4. The factory calculates its ending inventory level. If suffi cient inventory is available, ending inventory is beginning inven tory minus that period's actual demand. If there is not sufficient inventory, then back orders occur. When a back order occurs, your ending inventory value is negative. 5. The factory calculates its inventory position. Inventory position is the ending inventory plus any quantity already or dered that has not yet arrived. 6. If the factory's inventory position is at or below its reorder point, the factory releases an order to manufacturing. Procedures for all locations include the following: 1. At the end of each period, record the amount of actual ventory you have left, the actual number of back orders, the of holding the inventory, the cost of the back orders, and total cost. 2. Update your total statistics, that is, keep a running to the cases of inventory, the number of back orders, and the mulative holding costs, cumulative back order costs, and costs. End of Game Discussion Questions 1. How well does the distribution system seem to work? about it in terms of customer service, costs, effective use of i ventory, and information flows. 2. Given the amount of inventory in the system, why did back orders occur? 3. In this distribution chain, what happened to customer de- mand data? 4. How should customer demand data be communicated through the system? 5. What would you recommend be done differently?

Step by Step Solution

There are 3 Steps involved in it

Step: 1

1 The existing method is not very successful and some obvious problems need to be resolved What the ...

Get Instant Access to Expert-Tailored Solutions

See step-by-step solutions with expert insights and AI powered tools for academic success

Step: 2

Step: 3

Ace Your Homework with AI

Get the answers you need in no time with our AI-driven, step-by-step assistance

Get Started