Question

Industry background The medical supplies industry is a heterogeneous, innovative, and dynamic market. The global market for medical supplies is huge, and account for a

Industry background The medical supplies industry is a heterogeneous, innovative, and dynamic market. The global market for medical supplies is huge, and account for a significant proportion of health care costs as well as tremendously impacts the quality of living standard. Over the past few decades, the demand for medical supplies has been growing, mainly due to the growing prevalence of chronic diseases, respiratory illness, increasing cases of accidents & injuries which are escalating the market on the global platform. Additional factors driving the growth of the market include improving economic conditions and the increase demand for good health care. Recognizing the substantial burgeoning, the Market Research Philip centre (MRPC), recently published a report confirming that the global medical supplies market will be touching a valuation over Ringgit Malaysia 428 billion by 2022.

The medical supplies business delivers a wide range of healthcare materials ordered/prescribed by physicians and public, ranging from consumables and disposable to electronic medical devices. This market appears to be fiercely competitive and fragmented due to the presence of several matured as well as small but considerable players. These players try to sustain their market positions and gain a competitive advantage by means of acquisition, strategic partnership, expansion, product/technology launch, and market development. To achieve their goals, they must invest substantially and transpire massive investments in R&D to develop a cost-competitive portfolio. Such strategic initiatives not only help them to move into new markets, expand the sales team, and build the portfolio of medical products but also substantially help to off-load their burdens of debts.

The key players driving the global medical supplies market include Medtronic plc (Ireland), 3M Company (U.S.), B. Braun Melsungen AG (Germany), Johnson & Johnson (U.S.), Boston Scientific Corporation (U.S.), Baxter International Inc. (U.S.), Halyard Health, Inc. (U.S.), and Thermo Fisher Scientific Inc. (U.S.) among others.

Global Medical (GM)

Global Medical (GM) Berhad is a local based company and was originally established by a few licensed registered physicians in January 2010. Their main purpose of establishing the company is to deliver quality medical supplies to enhance the lives of people and encourage personal independence. It has gradually grown by acquisition of other small medical suppliers and is now listed on the Malaysian Stock Exchange. GM's primary objective is to remain as one of the leading national medical supply manufacturer. The firm has since expanded to offer health and wellness products.

Currently the company produces over 40,000 products from wound plasters to personal protection medical supplies. They strive to create innovative and quality products at a reasonable fair price. Among the personal protection medical supplies produced and sold, the two distinct products which are gaining tremendous demand are: surgical masks and surgical N95 respirator masks. The surgical masks product are manufactured by the Northern division and N95 respirators masks are produced by the southern division. Both Divisions operate with considerable autonomy and have diverse IT systems and practices which have been inherited from the smaller companies that GM acquired. The localized systems and practices make little difference to the work of the individual Divisions but affect centralized co- ordination and monitoring.

Personal Protection Medical Supplies (PPMS) The surgical masks or respirators are design and developed to meet the different hazard level of a specific work environments. Particularly, there are different protective properties imbedded for each type of personal protective product. Surgical and respirator masks are product that people consume(wear) to decrease the risk of infectious disease transmission between infected and non-infected persons. Since there is limited historical information on the effectiveness of surgical and respirator masks for the control of influenza during any previous pandemics, the effectiveness of surgical and respirators masks have been inferred on the basis of the mode of influenza transmission, particle size and professional judgment.

Respirator marks are mainly designed to reduce a worker's exposure to airborne contaminants. Respirators come in various sizes and must be individually selected to fit the wearer's face and to provide a tight seal. A proper seal between the user's face and the respirator forces inhaled air to be pulled through the respirator's filter material and not through gaps between the face and respirator. Respirators offer the best protection for workers who must work closely (either in contact with or within 6 feet) with people who have influenza-like symptoms. However, surgical masks are used as a physical barrier to protect the user from hazards, such as splashes of large droplets of blood or body fluids. Surgical masks also protect other people against infection from the person wearing the surgical mask. Such masks trap large particles of body fluids that may contain bacteria or viruses expelled by the wearer. Surgical masks are not designed or certified to prevent the inhalation of small airborne contaminants.

These particles are not visible to the naked eye but may still be capable of causing infection. Surgical masks are not designed to seal tightly against the user's face. During inhalation, much of the potentially contaminated air can pass through gaps between the face and the surgical masks. Their ability to filter small particles varies significantly based upon the type of material used to make the surgical mask, so they cannot be relied upon to protect workers against airborne infectious agents. Additional, surgical masks are not the same as respirators. Surgical masks are made to act as barriers to splashes or aerosols (such as the moisture from a sneeze), and they fit loosely to the face. Respirators are made to filter out airborne particles such as viruses and bacteria, and create a seal around the mouth and nose. They come in various grades including N95, N99, and N100, depending on the percentage of particles they are supposed to filter out. For instance in the case of N100 respirators, 99.97% of particles are prevented by using the mask. The authorized surgical respirators are approved by the NIOSH (the National Institute for Occupational Safety and Health).

Challenges faced by GM

Operating in an emerging markets, GM often face several challenges pertaining to product quality, regulatory compliance, and data security among several others. In terms of ensuring product quality, GM must adherence to product safety standards and regulatory compliance in all their manufacturing activities and processes. The compliance will warrant the production of top-notch product quality and avoid product recalls. Therefore adequate product safety, hygiene and reliability are extremely crucial to survive the competition in the emerging markets. The company also have to offer tailor-made products aimed at resolving unpredicted local demand and needs.For example, the necessity of overnight shipping which is due to the unexpected situations occur in the hospitals, where instance supplies are required. While one or two overnight orders will not have a detrimental impact on GM's bottom line but when this regularly occurs?as it inevitably will?

GM is starting to see significant losses in their revenues. In addition, to high shipping cost, GM faces high hidden costs such as inventory holding. This may include losses incurred by holding unavoidable aspect of expired products and excess supplies.To minimize this costs, Mr Peter the managing director of GM, proposes that the company should invest in a bespoke inventory integrate software, that have the ability to completely eliminate their overnight shipping costs that are caused by stockouts. While some emergency items may need to be overnight on an occasional basis, the regularity of the situation will drop dramatically.

The software would provide a holistic approach to pricing their products, including the costs associated with moving and managing the supplies as well as effectively handle product utilization, special deliveries, internal distribution, and much more. However, Mr Peter is worried, that the IT integration and data security may pose technical challenges for the company. There is also a growing concern of GM to collect, secure, and manage vast amounts of sensitive data that is stored in a cloud-based infrastructure which may be subject to data theft and breaches.

Management Accounting Control System (MACS)

GM financial objective further includes to maximize shareholder wealth through innovation and continuous technological improvement in its products. GEM has a well-established incremental budgeting process. Divisional managers forecast sales volumes and costs months in advance of the budget year. These divisional budgets are then scrutinized by the main board, and revised significantly by them in line with targets they have set for the business. The finalized budgets are often approved after the start of the accounting year. Under pressure to deliver consistent returns to institutional shareholders, the board does not tolerate failure by either division to achieve the planned net profit for the year once the budget is approved.

Last year's results were poor compared to the annual budget. Divisional managers, who are appraised on the financial performance of their own division, have complained about the length of time that the budgeting process takes and that the performance of their divisions could have been better but was constrained by the budgets which were set for them. In February 2021, the division managers had failed to anticipate the sudden high popularity of a surgical and respiratory masks, and had not made the necessary technical and capacity adjustment to their production system. This was due to the high costs of doing so, which had not been budgeted for. Based on the original sales forecast, both Division had already committed to reduce the manufacturing of large quantities of the masks and now had to heavily produce in order to meet the sudden surge of sales volumes. Furthermore, a critical material in the manufacture of GM products are of such as wool felt, fiberglass paper, or polypropylene, that are subject to changes in price according to worldwide supply and demand.

During the year supplies of polypropylene were reduced significantly for a short period of time and Southern division had to paid high prices to ensure continues supply. Managers of Southern division were unaware that Northern division held large inventories of such materials which they had purchased earlier when the price was much lower. Last year, both divisions accurately forecasted demand for its components based on the previous years' sales volumes plus the historic annual growth rate of 10%. However, overall sales volume of Southern Division was much lower than budgeted. This was due to a fire at the factory of their main customer (consumes 55% of division operation capacity), which was then closed for part of the year.

Reacting to this news, manager of Southern division took action to reduce costs, including closing one of the two of the production facilities in the division. However, this year given the sudden surge of demand, Southern Division manager was unwilling to recruit extra staff to cope with increased demand; nor would Northern Division re-allocate shared manufacturing facilities to them, in case demand increased for its own products later in the year. As a result, GM lost the prestigious preferred supplier status from their main customer who was unhappy with Southern Division's failure to effectively respond to the additional demand. The customer had been forced to purchase a more expensive, though technically superior, component from an alternative manufacturer. The institutional shareholders' representative, recently appointed to the board, has raised many important questions.

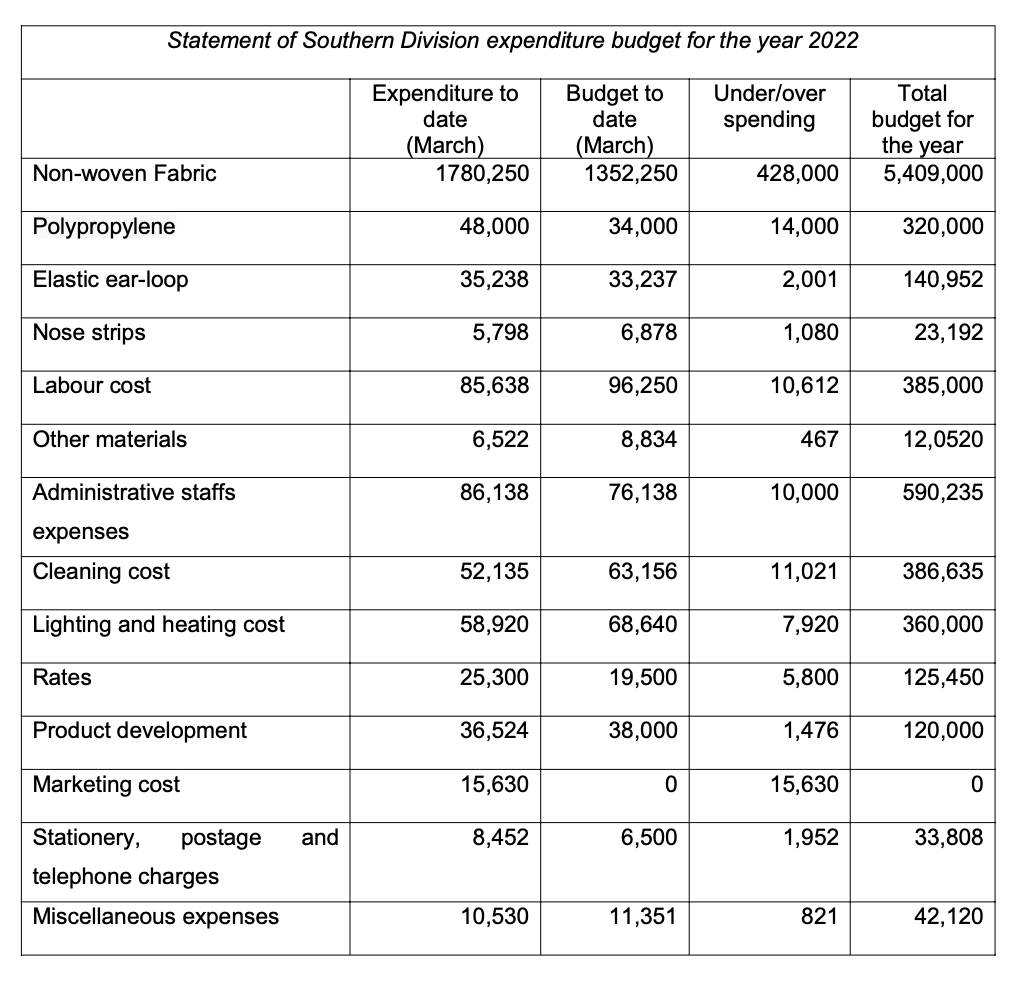

'We need to know whether GM budgeting process is appropriate for the business, and how this contributed to last year's poor performance', she said, 'and more importantly, how do we need to change the process to prevent this happening in the future'. According to her a competent and robust management accounting system should enable to enhance the performance of a company by considering the challenges and behavioural consequence of its application. She also noted that the company needs to employ a qualified management accountant to oversee matters related to planning, control and management of the budgeting control system. The budget statement prepared by the cost control clerk is reproduced as below. It covers the 12 month to the end of December 2022 and all figures refer to cash payments made.

Statement of Southern Division expenditure budget for the year 2022 Expenditure to date Budget to Under/over date spending (March) (March) Total budget for the year Non-woven Fabric Polypropylene Elastic ear-loop 1780,250 1352,250 428,000 5,409,000 48,000 34,000 14,000 320,000 35,238 33,237 2,001 140,952 Nose strips 5,798 6,878 1,080 23,192 Labour cost 85,638 96,250 10,612 385,000 Other materials 6,522 8,834 467 12,0520 Administrative staffs 86,138 76,138 10,000 590,235 expenses Cleaning cost 52,135 63,156 11,021 386,635 Lighting and heating cost 58,920 68,640 7,920 360,000 Rates 25,300 19,500 5,800 125,450 Product development 36,524 38,000 1,476 120,000 Marketing cost 15,630 0 15,630 0 Stationery, postage and 8,452 6,500 1,952 33,808 telephone charges Miscellaneous expenses 10,530 11,351 821 42,120

Step by Step Solution

There are 3 Steps involved in it

Step: 1

Get Instant Access to Expert-Tailored Solutions

See step-by-step solutions with expert insights and AI powered tools for academic success

Step: 2

Step: 3

Ace Your Homework with AI

Get the answers you need in no time with our AI-driven, step-by-step assistance

Get Started