Answered step by step

Verified Expert Solution

Question

1 Approved Answer

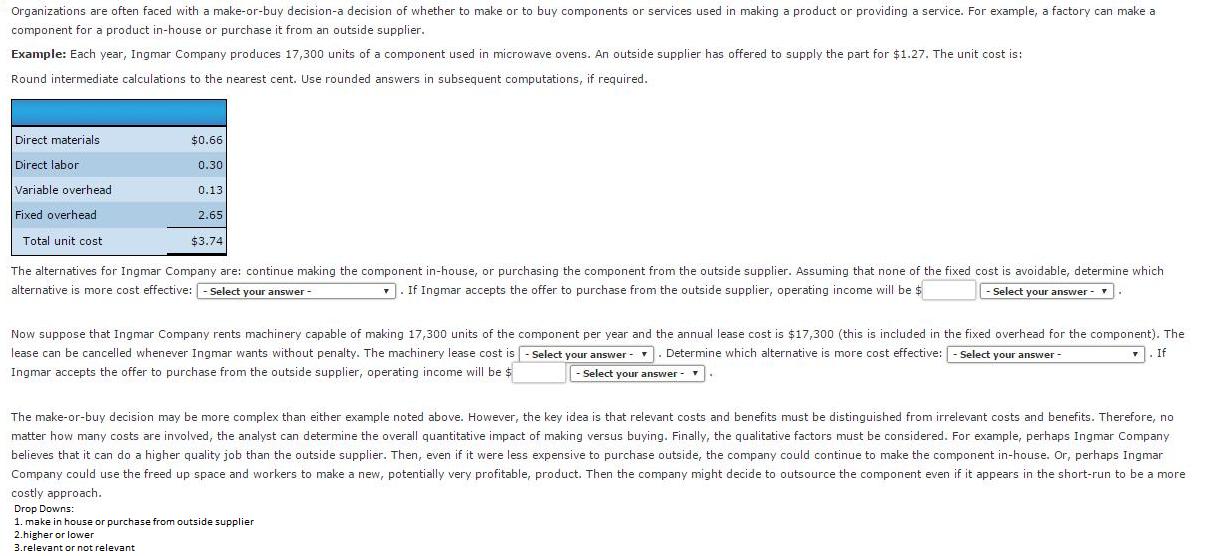

Organizations are often faced with a make-or-buy decision-a decision of whether to make or to buy components or services used in making a product

Organizations are often faced with a make-or-buy decision-a decision of whether to make or to buy components or services used in making a product or providing a service. For example, a factory can make a component for a product in-house or purchase it from an outside supplier. Example: Each year, Ingmar Company produces 17,300 units of a component used in microwave ovens. An outside supplier has offered to supply the part for $1.27. The unit cost is: Round intermediate calculations to the nearest cent. Use rounded answers in subsequent computations, if required. Direct materials $0.66 Direct labor 0.30 Variable overhead 0.13 Fixed overhead 2.65 Total unit cost $3.74 The alternatives for Ingmar Company are: continue making the component in-house, or purchasing the component from the outside supplier. Assuming that none of the fixed cost is avoidable, determine which alternative is more cost effective: - Select your answer - If Ingmar accepts the offer to purchase from the outside supplier, operating income will be $ - Select your answer - Now suppose that Ingmar Company rents machinery capable of making 17,300 units of the component per year and the annual lease cost is $17,300 (this is included in the fixed overhead for the component). The lease can be cancelled whenever Ingmar wants without penalty. The machinery lease cost is - Select your answer - . Determine which alternative is more cost effective: - Select your answer - 1. If Ingmar accepts the offer to purchase from the outside supplier, operating income will be $ - Select your answer - The make-or-buy decision may be more complex than either example noted above. However, the key idea is that relevant costs and benefits must be distinguished from irrelevant costs and benefits. Therefore, no matter how many costs are involved, the analyst can determine the overall quantitative impact of making versus buying. Finally, the qualitative factors must be considered. For example, perhaps Ingmar Company believes that it can do a higher quality job than the outside supplier. Then, even if it were less expensive to purchase outside, the company could continue to make the component in-house. Or, perhaps Ingmar Company could use the freed up space and workers to make a new, potentially very profitable, product. Then the company might decide to outsource the component even if it appears in the short-run to be a more costly approach. Drop Downs: 1. make in house or purchase from outside supplier 2.higher or lower 3.relevant or not relevant

Step by Step Solution

★★★★★

3.50 Rating (167 Votes )

There are 3 Steps involved in it

Step: 1

Ingmar produce 17300 units in house Cost per unit 374 Total cost 17300374 6470...

Get Instant Access to Expert-Tailored Solutions

See step-by-step solutions with expert insights and AI powered tools for academic success

Step: 2

Step: 3

Ace Your Homework with AI

Get the answers you need in no time with our AI-driven, step-by-step assistance

Get Started