Question

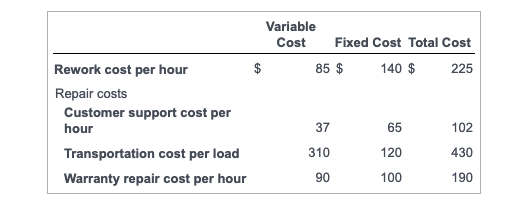

Intelprint manufactures and sells 23,000 high-technology printing presses each year. The variable and fixed costs of rework and repair are as follows: Requirement 1. Should

Intelprint manufactures and sells 23,000 high-technology printing presses each year. The variable and fixed costs of rework and repair are as follows:

Requirement 1. Should nano print change to the new component? Show your calculations

| New Component cost x | Presses sold = | Relevant costs |

Select the formula you will use to calculate the relevant benefits of the quality items

| Variable cost per hour/ load x | Hours/loads saved =

| Relevant benefits of quality items | |

| Savings on rework costs | |||

| Savings in customer support costs | |||

| Savings in transportation costs | |||

| Savings in warranty repair costs |

Select the formula you will use to calculate the total relevant benefits and then calculate the amount

| Relevenat benefits of quality items + | Opportunity cost = | Total relevant benefits |

What is the expected relevant costs of the new component? ___________

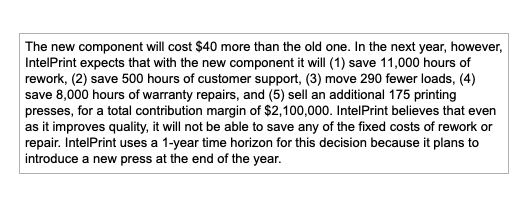

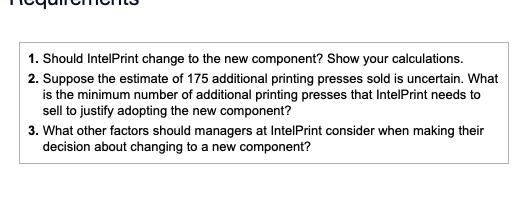

Variable Cost Fixed Cost Total Cost 85 $ 140 $ 225 Rework cost per hour Repair costs Customer support cost per hour Transportation cost per load Warranty repair cost per hour 37 65 102 310 120 430 90 100 190 The new component will cost $40 more than the old one. In the next year, however, IntelPrint expects that with the new component it will (1) save 11,000 hours of rework, (2) save 500 hours of customer support, (3) move 290 fewer loads, (4) save 8,000 hours of warranty repairs, and (5) sell an additional 175 printing presses, for a total contribution margin of $2,100,000. IntelPrint believes that even as it improves quality, it will not be able to save any of the fixed costs of rework or repair. IntelPrint uses a 1-year time horizon for this decision because it plans to introduce a new press at the end of the year. 1. Should IntelPrint change to the new component? Show your calculations. 2. Suppose the estimate of 175 additional printing presses sold is uncertain. What is the minimum number of additional printing presses that Intel Print needs to sell to justify adopting the new component? 3. What other factors should managers at IntelPrint consider when making their decision about changing to a new component

Step by Step Solution

There are 3 Steps involved in it

Step: 1

Get Instant Access to Expert-Tailored Solutions

See step-by-step solutions with expert insights and AI powered tools for academic success

Step: 2

Step: 3

Ace Your Homework with AI

Get the answers you need in no time with our AI-driven, step-by-step assistance

Get Started