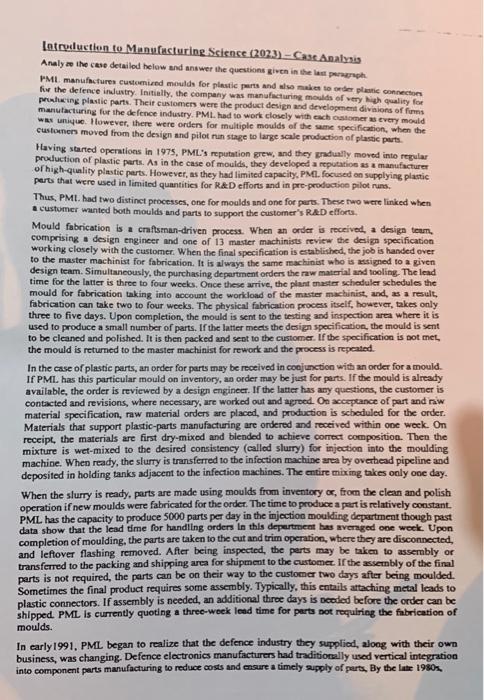

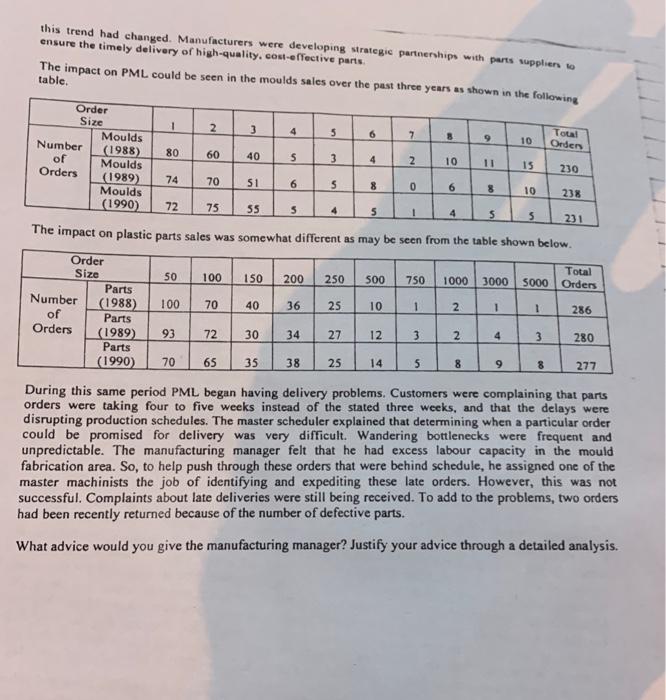

Intruduction to Manufacturing Sicience (2023)-Case Analbis Analy a the case detailod helow and answer the quevions given in the lakt perapaph. HM1. manufactures custcemired moulds for plastic parts and wlso makes to onder platic connecton for the defence industry. Initielly, the company was manulweturing moulds of very bieh quality for prualueing plastic parts. Their customers were the product design and development divaions of furms manutacturing fur the defence industry. PML, had to work closely with each cosasmer as every mould was uniyuo. However, there were onden for multiple moulds of the same specification, when the custouners moved from the design and pilot nin stage to large seale prodoction of plastic parts. Having started openatioes in 1975 , PML's reputation grew, and they gradually moved into regular production of plastic parts. As in the case of moulds, they developed a reputation as a manufacturer or high-quality plastic perts. However, as they had limited capacity, PME. focused an supplying plastic pers that were used in limited quantitics for RAD efforts and in pre-prodoctioe pilot rums. Thus, PML. had two distinct processes, one for moulds and one for parts. These two were linked when a sustumer wanted both moulds and parts to support the customer's R.ED efforts. Mould fabrication is a craftsman-driven process. When an order is received, a design team, comprising a design engincer and one of 13 master machinists review the design specification working closely with the customer. When the final specification is established, the job is handed over to the master machinist for fabrication. It is always the same machinist who is astigned to a given design team. Simultaneously, the purchasing department orders the raw material and tooling. The lead time for the latter is throe to four weeks. Once these arrive, the plant master scheduler schedules the mould for fabrication taking into account the workload of the master machinist, and, as a result, fabrication can take two to four weeks. The physical fabrication process itself, however, takes only three to five days. Upon completion, the mould is sent to the testing and inspection area where it is used to produce a small number of parts. If the latter meets the design specification, the mould is sent to be cleaned and polished. It is then packed and sent to the customer. If the specification is pot met, the mould is returned to the master machinist for rework and the process is repeated. In the case of plastic parts, an order for parts may be received in conjunction with an order for a mould. If PML, has this purticular mould on inventory, aa order may be just for parts. If the mould is alreaty available, the order is reviewed by a design engineer. If the latter has any questions, the custorner is contacted and revisions, where necessary, are worked out and agreed. On acceppeance of part and riw material specification, raw material orders are placed, and production is scbeduled for the order. Materials that support plastic-parts manufacturing are ondered and received within ooe week. On receipt, the materials are first dry-mixed and blended to achieve correct composition. Then the mixture is wet-mixed to the desired consistency (ealled slury) for injection into the moulding machine. When ready, the slumy is transferred to the infection machine area by overhead pipeline and deposited in holding tanks adjacent to the infection machines. The entire mixing takes only one day. When the slurry is ready, parts are made using moulds from inventory or, from the elean and polish Wperation if new moulds were fabricated for the order. The time to produce a pert is relatively constant. PML has the eapacity to produce 5000 parts per day in the injection moulding depurtment though past data show that the lead time for handing orders in this department has averaged one week. Upon completion of moulding, the parts are taken to the cut and trim operation, where they are disconnected, and leftover flashing removed. After being inspected, the parts may be taken to assembly or transferred to the packing and shipping area for shipment to the customer. If the assembly of the final parts is not required, the parts can be on their way to the customer two days after being moulded. ports is not required, the parts can be on the final product requires some assembly. Typically, this entails attaching metal leads to plastic connectors. If assembly is needed, an additional three days is needed before the order can be plastic connectors. If assembly is needed, an additional thee days is oceded belore the order can be shlpped. PML is currently quoting a three-week lead time for perta not requiring the falorication of moulds. In early 1991, PML began to realize that the defence industry they supplied, along with their own business, was changing. Defence electronics manufacturers had traditionally used vertical integration business, was changing. Delence electronics manponent parts manufacturing to reduce costs and ensure a timely supply of parts, By the late 1930 , this trend had changed. Manufacturers were developing strategic partnerships with parts supplien to ensure the timely delivery of high-quality, cost-effective parts The impact on PML could be seen in the moulds sales over the past three years as shown in the fan. table. The impact on plastic parts sales was somewhat different as may be seen from the table shown below. During this same period PML began having delivery problems. Customers were complaining that parts orders were taking four to five weeks instead of the stated three weeks, and that the delays were disrupting production schedules. The master scheduler explained that determining when a particular order could be promised for delivery was very difficult. Wandering bottlenecks were frequent and unpredictable. The manufacturing manager felt that he had excess labour capacity in the mould fabrication area. So, to help push through these orders that were behind schedule, he assigned one of the master machinists the job of identifying and expediting these late orders. However, this was not successful. Complaints about late deliveries were still being received. To add to the problems, two orders had been recently returned because of the number of defective parts. What advice would you give the manufacturing manager? Justify your advice through a detailed analysis