Question

Inventory Planning . Rowers North, Inc. (RNI) would like to develop an inventory policy that will minimize the total cost associated with the companys inventory

Inventory Planning. Rowers North, Inc. (RNI) would like to develop an inventory policy that will minimize the total cost associated with the company’s inventory of rowing machines, while ensuring that few customers are unable to purchase a machine the day they walk in the store. The type of inventory policy they prefer involves a fixed reorder point and order quantity. The reorder point is the level of inventory at which an order is sent to the supplier. The order quantity is the amount ordered each time. These are decision variables, but once chosen, they will not be changed.

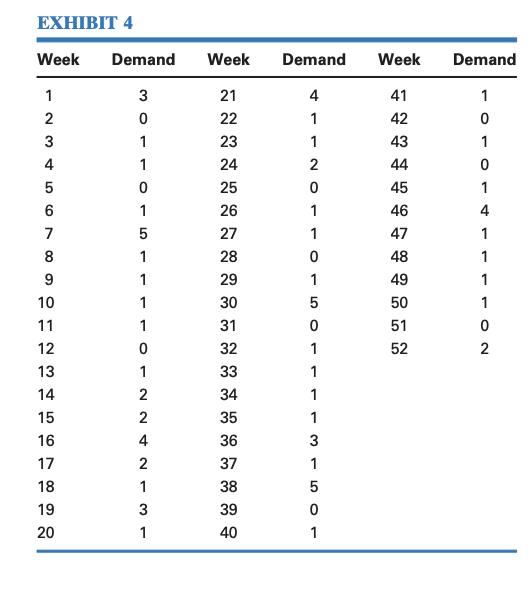

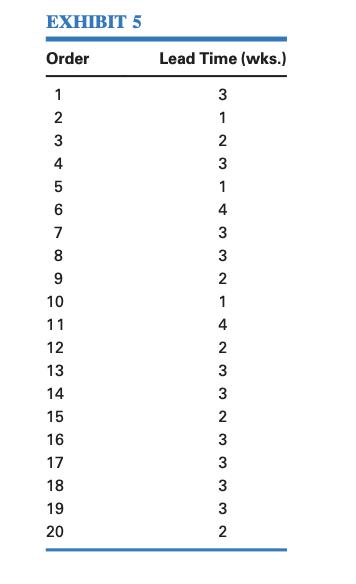

Inventory planning at RNI is complicated by several factors. One is uncertainty in demand. Weekly demand can range from zero to five machines. Data covering the past year is given in Exhibit 4. A further complication is that the time it takes for an order to arrive from the manufacturer is variable. This lead time has been as long as four weeks. Exhibit 5 gives the actual lead times for the twenty most recent orders. (Once an order has been placed, the lead time is determined by the supplier and communicated to RNI.)

Some of the relevant cost data are known. For example, it costs $1 per week to hold a rowing machine in inventory, and it costs $50 to place an order (regardless of its size).

One of the central issues for RNI is the cost of being out of stock. Since there are a number of competing retailers in the area, it is common for a customer who doesn’t find the preferred machine in stock to leave and look for it elsewhere. Some customers may be loyal enough to wait until the product is back in stock, but even those customers may be displeased by the service they receive. The VP of marketing has suggested that the cost of an unsatisfied customer is simply the forgone margin on the lost sale (roughly $50 per machine). Others in the company argue that the cost is less, perhaps much less.

Note that if RNI places an order in every week in which final inventory falls below the reorder point, it may find itself with multiple, redundant orders arriving in subsequent weeks. To control this, firms typically track their order backlog (i.e., the quantity of units ordered but not yet received). They then take the backlog into account when deciding whether to order in a given week.

a. Estimate the total cost for a reorder point of 1 and a reorder quantity of 5.

b. Determine an optimal reorder point and order quantity. c. How sensitive is the optimal solution to the cost of an

unsatisfied customer (in the range from $25 to $75)?

EXHIBIT 4 Week 1 23456 7 8 9 10 11 12 13 14 15 16 17 18 19 20 Demand 3 0 1 1 0 1 5 1 1 1 1 0 1 2 2 4 2131 Week 21 22 23 24 25 26 27 28 29 30 31 32 33 34 35 36 37 38 39 40 Demand 4 1 1 2 0 1 1 0 1 5 0 1 1 1 1 3 1 5 0 1 Week 41 42 43 44 45 46 47 48 49 50 51 52 Demand 1 0 1 0 1 4 1 1 1 1 0 NO 2

Step by Step Solution

3.42 Rating (142 Votes )

There are 3 Steps involved in it

Step: 1

Some amount M of goods is in stock to begin with As sales continue the stock decreases At the predef...

Get Instant Access to Expert-Tailored Solutions

See step-by-step solutions with expert insights and AI powered tools for academic success

Step: 2

Step: 3

Ace Your Homework with AI

Get the answers you need in no time with our AI-driven, step-by-step assistance

Get Started