It costs Swift $200 to place an order with the suppliers. This amount covers the corresponding internal ordering costs and the costs of delivering the

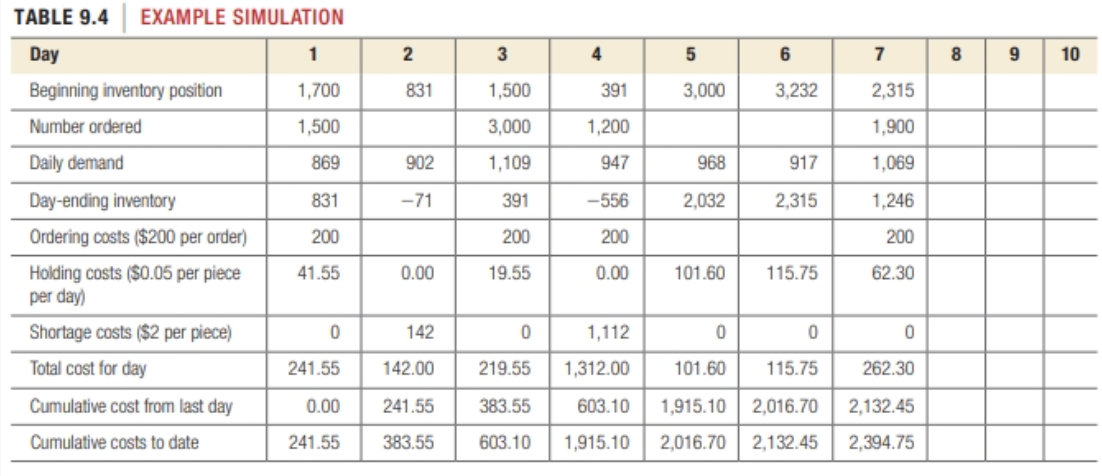

It costs Swift $200 to place an order with the suppliers. This amount covers the corresponding internal ordering costs and the costs of delivering the products to the company. Holland estimates that the cost of lost sales amounts to $2 per unit of DRAM. This rough estimate includes the loss of profits, as well as the intangible damage to customer goodwill. To simplify its inventory management system, Swift has a policy of maintaining a cycle-service level of 95 percent. The holding cost per day per unit is estimated to be 0.5 percent of the cost of goods, regardless of the product. Inventory holding costs are calculated on the basis of the ending inventory each day. The current balance is 1,700 units of DRAM in stock. The daily purchasing routine is as follows. Orders are placed at the beginning of the day, before Swift is open for customer business. The orders arrive at the beginning of the day, 2 days later, and can be used for sales that day. For example, an order placed at the beginning of day 1 will arrive at Swift before Swift is open for business on day 3. The actual daily demand is always recorded at the end of the day, after Swift has closed for customer business.

Holland believes that simulation is a useful approach to assess various inventory control alternatives. The historical data from Table 9.3 could be used to develop attractive inventory policies. The table was developed to record various costs and evaluate different alternatives. An example showing some recent DRAM inventory decisions is shown in Table 9.4.

Design a new inventory system for Swift Electronic Supply, Inc., using the data provided.

Provide the rationale for your system, which should include the decision rules you would follow to determine how much to order and when.

TABLE 9.4 EXAMPLE SIMULATION 6 10 Day 1 2 3 4 5 6 7 8 Beginning inventory position 1,700 831 1,500 391 3,000 3,232 2,315 Number ordered 1,500 3,000 1,200 1,900 Daily demand 869 902 1,109 947 968 917 1,069 Day-ending inventory 831 -71 391 -556 2,032 2,315 1,246 Ordering costs ($200 per order) 200 200 200 200 Holding costs ($0.05 per piece 41.55 0.00 19.55 0.00 101.60 115.75 62.30 per day) Shortage costs ($2 per piece) 0 142 0 1,112 0 0 0 Total cost for day 241.55 142.00 219.55 1,312.00 101.60 115.75 262.30 Cumulative cost from last day 0.00 241.55 383.55 603.10 1,915.10 2,016.70 2,132.45 Cumulative costs to date 241.55 383.55 603.10 1,915.10 2,016.70 2,132.45 2,394.75

Step by Step Solution

There are 3 Steps involved in it

Step: 1

To design a new inventory system for Swift Electronic Supply Inc Ill outline a system based on the provided data and rationale including key decision rules to help determine when to order and how much ...

See step-by-step solutions with expert insights and AI powered tools for academic success

Step: 2

Step: 3

Ace Your Homework with AI

Get the answers you need in no time with our AI-driven, step-by-step assistance

Get Started