Answered step by step

Verified Expert Solution

Question

1 Approved Answer

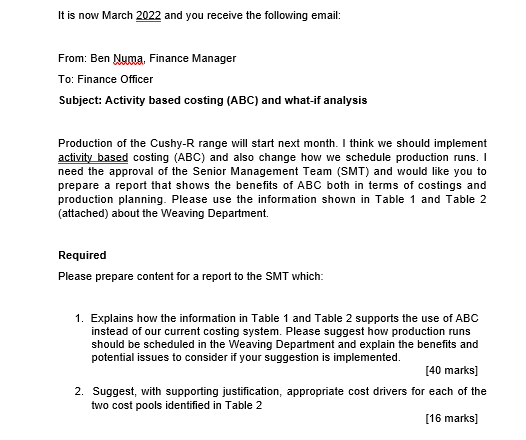

It is now March 2022 and you receive the following email: From: Ben Numa, Finance Manager To: Finance Officer Subject: Activity based costing (ABC)

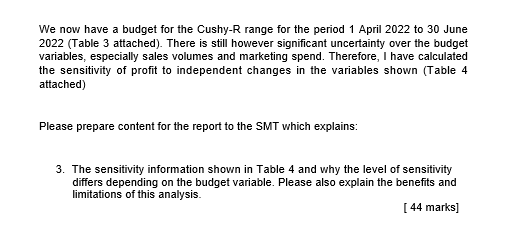

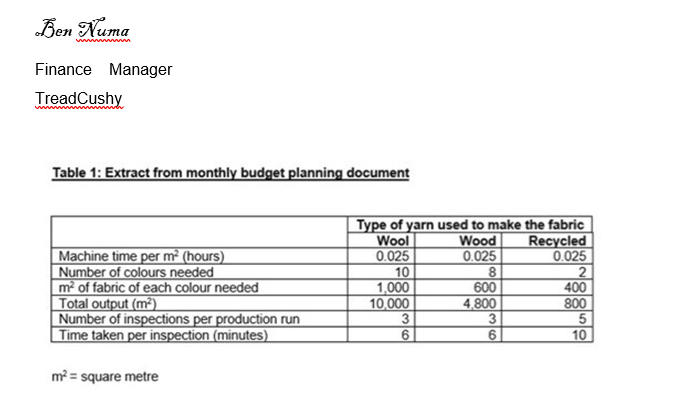

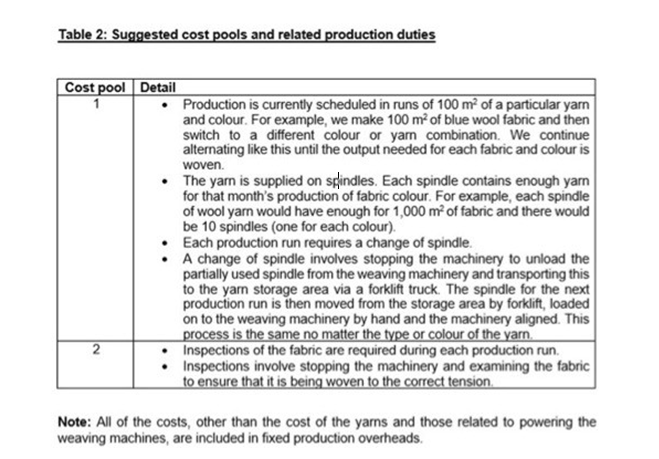

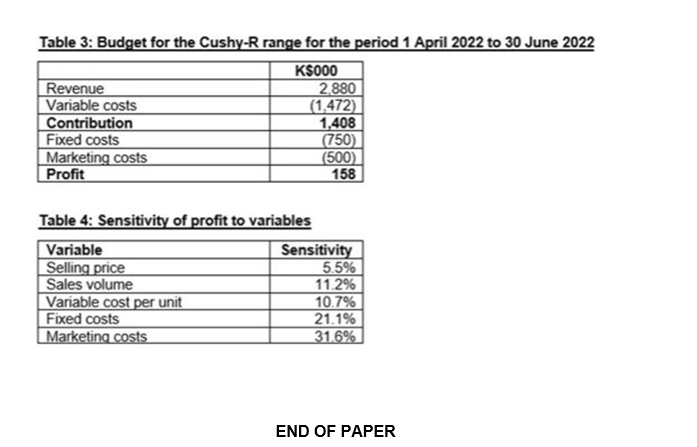

It is now March 2022 and you receive the following email: From: Ben Numa, Finance Manager To: Finance Officer Subject: Activity based costing (ABC) and what-if analysis Production of the Cushy-R range will start next month. I think we should implement activity based costing (ABC) and also change how we schedule production runs. I need the approval of the Senior Management Team (SMT) and would like you to prepare a report that shows the benefits of ABC both in terms of costings and production planning. Please use the information shown in Table 1 and Table 2 (attached) about the Weaving Department. Required Please prepare content for a report to the SMT which: 1. Explains how the information in Table 1 and Table 2 supports the use of ABC instead of our current costing system. Please suggest how production runs should be scheduled in the Weaving Department and explain the benefits and potential issues to consider if your suggestion is implemented. [40 marks] 2. Suggest, with supporting justification, appropriate cost drivers for each of the two cost pools identified in Table 2 [16 marks] We now have a budget for the Cushy-R range for the period 1 April 2022 to 30 June 2022 (Table 3 attached). There is still however significant uncertainty over the budget variables, especially sales volumes and marketing spend. Therefore, I have calculated the sensitivity of profit to independent changes in the variables shown (Table 4 attached) Please prepare content for the report to the SMT which explains: 3. The sensitivity information shown in Table 4 and why the level of sensitivity differs depending on the budget variable. Please also explain the benefits and limitations of this analysis. [44 marks] Ben Numa Finance Manager TreadCushy Table 1: Extract from monthly budget planning document Type of yarn used to make the fabric Machine time per m (hours) Number of colours needed m of fabric of each colour needed Total output (m2) Number of inspections per production run Time taken per inspection (minutes) m = square metre Wool Wood Recycled 0.025 0.025 0.025 10 8 2 1,000 600 400 10,000 4,800 800 3 5 6 6 10 Table 2: Suggested cost pools and related production duties Cost pool 1 2 Detail Production is currently scheduled in runs of 100 m of a particular yarn and colour. For example, we make 100 m of blue wool fabric and then switch to a different colour or yam combination. We continue alternating like this until the output needed for each fabric and colour is woven. The yarn is supplied on spindles. Each spindle contains enough yarn for that month's production of fabric colour. For example, each spindle of wool yarn would have enough for 1,000 m of fabric and there would be 10 spindles (one for each colour). Each production run requires a change of spindle. A change of spindle involves stopping the machinery to unload the partially used spindle from the weaving machinery and transporting this to the yarn storage area via a forklift truck. The spindle for the next production run is then moved from the storage area by forklift, loaded on to the weaving machinery by hand and the machinery aligned. This process is the same no matter the type or colour of the yarn. Inspections of the fabric are required during each production run. Inspections involve stopping the machinery and examining the fabric to ensure that it is being woven to the correct tension. Note: All of the costs, other than the cost of the yarns and those related to powering the weaving machines, are included in fixed production overheads. Table 3: Budget for the Cushy-R range for the period 1 April 2022 to 30 June 2022 Contribution Revenue Variable costs Fixed costs Marketing costs Profit K$000 2,880 (1,472) 1,408 (750) (500) 158 Table 4: Sensitivity of profit to variables Variable Sensitivity Selling price 5.5% Sales volume 11.2% Variable cost per unit 10.7% Fixed costs 21.1% Marketing costs 31.6% END OF PAPER

Step by Step Solution

There are 3 Steps involved in it

Step: 1

Get Instant Access to Expert-Tailored Solutions

See step-by-step solutions with expert insights and AI powered tools for academic success

Step: 2

Step: 3

Ace Your Homework with AI

Get the answers you need in no time with our AI-driven, step-by-step assistance

Get Started