Answered step by step

Verified Expert Solution

Question

1 Approved Answer

iv. Anokye's company can produce a part it uses in an assembly operation at the rate of 50 an hour. The company operates eight hours

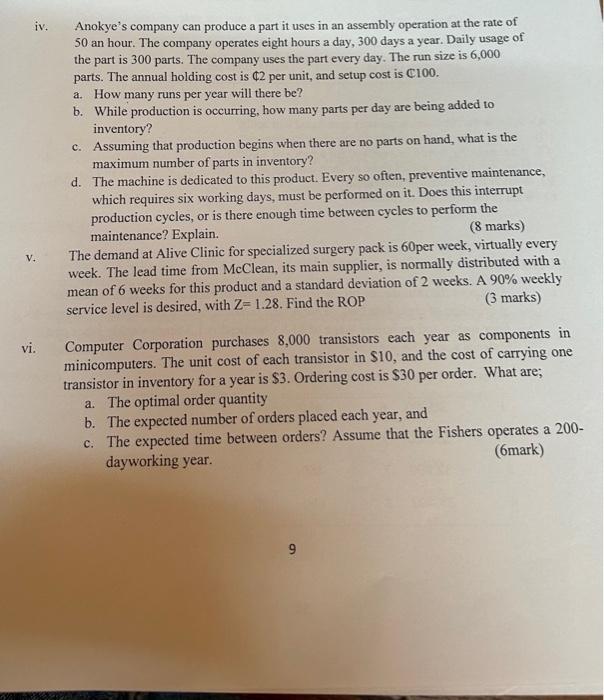

iv. Anokye's company can produce a part it uses in an assembly operation at the rate of 50 an hour. The company operates eight hours a day, 300 days a year. Daily usage of the part is 300 parts. The company uses the part every day. The run size is 6,000 parts. The annual holding cost is $2 per unit, and setup cost is C100. a. How many runs per year will there be? b. While production is occurring, how many parts per day are being added to inventory? c. Assuming that production begins when there are no parts on hand, what is the maximum number of parts in inventory? d. The machine is dedicated to this product. Every so often, preventive maintenance, which requires six working days, must be performed on it. Does this interrupt production cycles, or is there enough time between cycles to perform the maintenance? Explain. (8 marks) The demand at Alive Clinic for specialized surgery pack is 60per week, virtually every week. The lead time from McClean, its main supplier, is normally distributed with a mean of 6 weeks for this product and a standard deviation of 2 weeks. A 90% weekly (3 marks) service level is desired, with Z= 1.28. Find the ROP Computer Corporation purchases 8,000 transistors each year as components in minicomputers. The unit cost of each transistor in $10, and the cost of carrying one transistor in inventory for a year is $3. Ordering cost is $30 per order. What are; a. The optimal order quantity b. The expected number of orders placed each year, and c. The expected time between orders? Assume that the Fishers operates a 200- dayworking year. (6mark) 9

Step by Step Solution

There are 3 Steps involved in it

Step: 1

Get Instant Access to Expert-Tailored Solutions

See step-by-step solutions with expert insights and AI powered tools for academic success

Step: 2

Step: 3

Ace Your Homework with AI

Get the answers you need in no time with our AI-driven, step-by-step assistance

Get Started